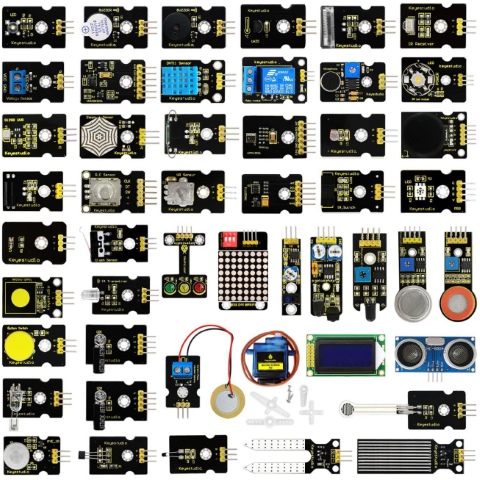

Keyestudio 48 in 1 Sensor Kit

1.Description

This sensor kit which is compatible with various microcontrollers and Raspberry Pi contains 48 commonly used sensors and modules including an active buzzer module, a 5V relay module, a temperature and humidity module and others.

At the same time, some detailed projects for each sensor based on development board are also provided, such as wiring methods and test code. With the help of this kit, you could not only obtain interesting knowledge about them but also make substantial interactive projects.

Note that in the following projects, the main board and other wires are not included in this kit.

Tutorial and code download:KS0522 Tutorial

2.Component List

No. |

Components |

Quantity |

Picture |

|---|---|---|---|

1 |

White LED Module |

1 |

|

2 |

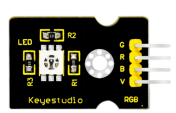

RGB LED Module |

1 |

|

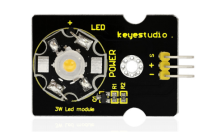

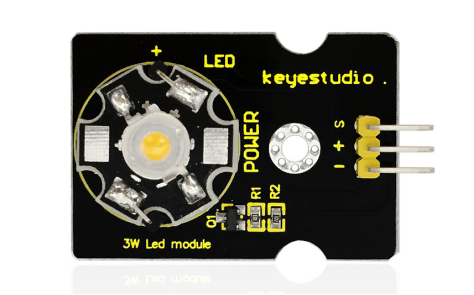

3 |

3W LED Module |

1 |

|

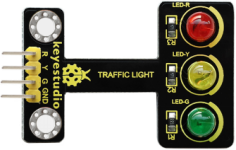

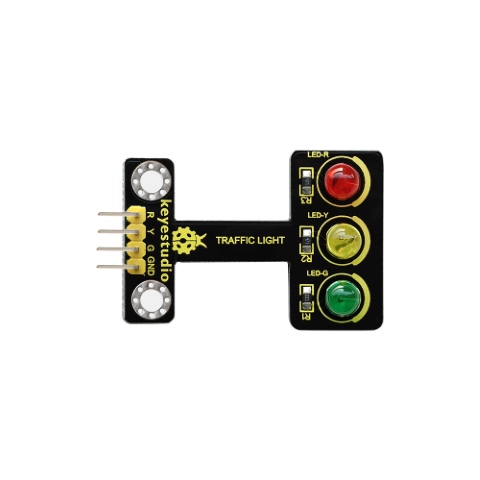

4 |

Traffic Light Module |

1 |

|

5 |

Active Buzzer Module |

1 |

|

6 |

Passive Buzzer Module |

1 |

|

7 |

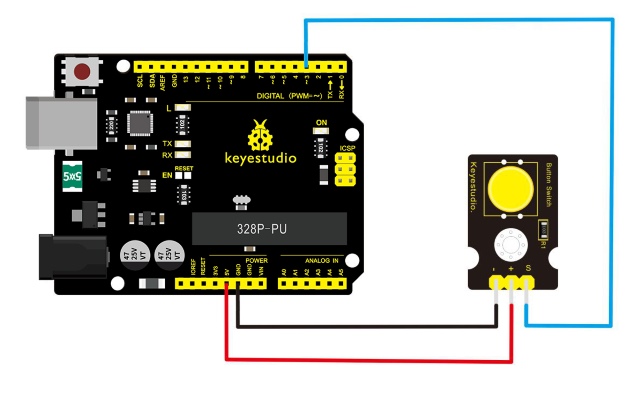

Digital Push Button Module |

1 |

|

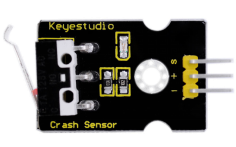

8 |

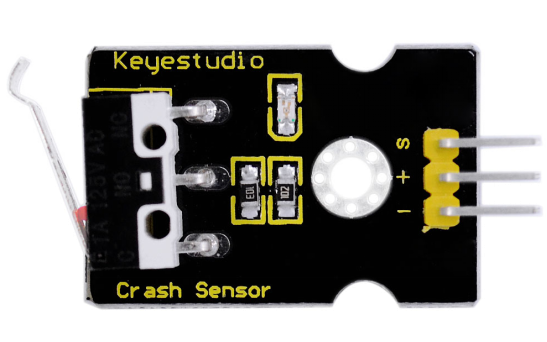

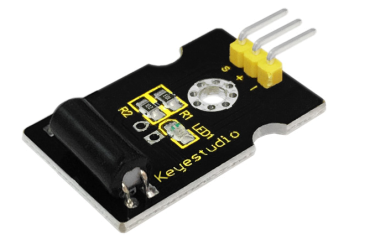

Collision Sensor |

1 |

|

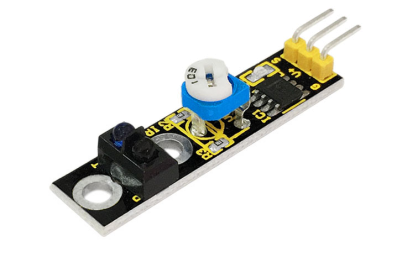

9 |

Line Tracking Sensor |

1 |

|

10 |

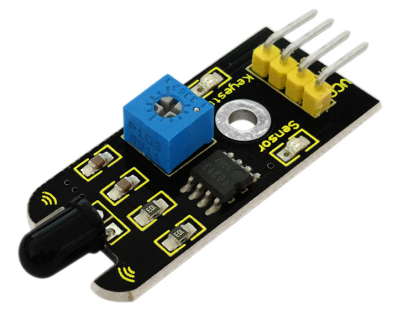

Infrared Obstacle Avoidance Sensor |

1 |

|

11 |

Photo Interrupter Module |

1 |

|

12 |

Hall Magnetic Sensor |

1 |

|

13 |

Knock Sensor Module |

1 |

|

14 |

Digital Tilt Sensor |

1 |

|

15 |

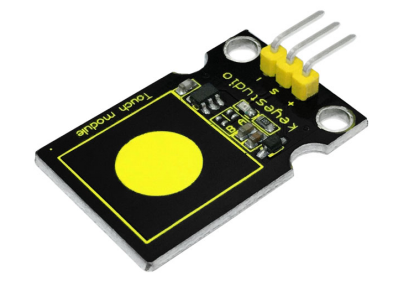

Capacitive Touch Sensor |

1 |

|

16 |

Flame Sensor |

1 |

|

17 |

Reed Switch Module |

1 |

|

18 |

PIR Motion Sensor |

1 |

|

19 |

Analog Temperature Sensor |

1 |

|

20 |

Analog Rotation Sensor |

1 |

|

21 |

Photocell Sensor |

1 |

|

22 |

Analog Sound Sensor |

1 |

|

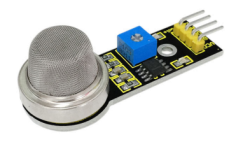

23 |

Water Sensor |

1 |

|

24 |

Soil Humidity Sensor |

1 |

|

25 |

Analog Gas Sensor |

1 |

|

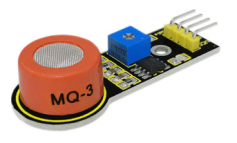

26 |

Analog Alcohol Sensor |

1 |

|

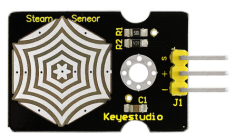

27 |

Steam Sensor |

1 |

|

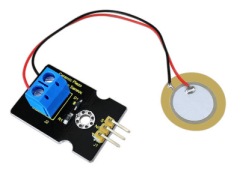

28 |

Analog Piezoelectric Ceramic Vibration Sensor |

1 |

|

29 |

Voltage Sensor |

1 |

|

30 |

Thin-film Pressure Sensor |

1 |

|

31 |

TEMT6000 Ambient Light Sensor |

1 |

|

32 |

GUVA-S12SD 3528 Ultraviolet Sensor |

1 |

|

33 |

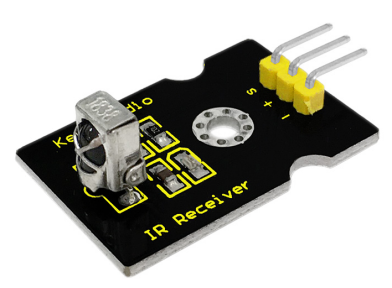

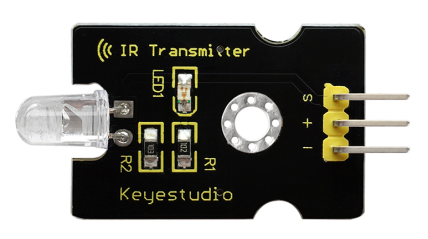

Digital IR Receiver Module |

1 |

|

34 |

Digital IR Transmitter Module |

1 |

|

35 |

Pulse Rate Monitor Module |

1 |

|

36 |

Joystick Module |

1 |

|

37 |

Rotary Encoder Module |

1 |

|

38 |

5V 1 Channel Relay Module |

1 |

|

39 |

LM35 Linear Temperature Sensor |

1 |

|

40 |

DHT11 Temperature and Humidity Sensor |

1 |

|

41 |

Magical Light Cup Module |

2 |

|

42 |

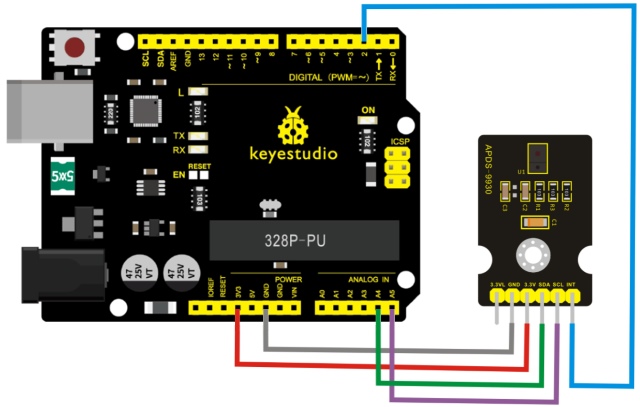

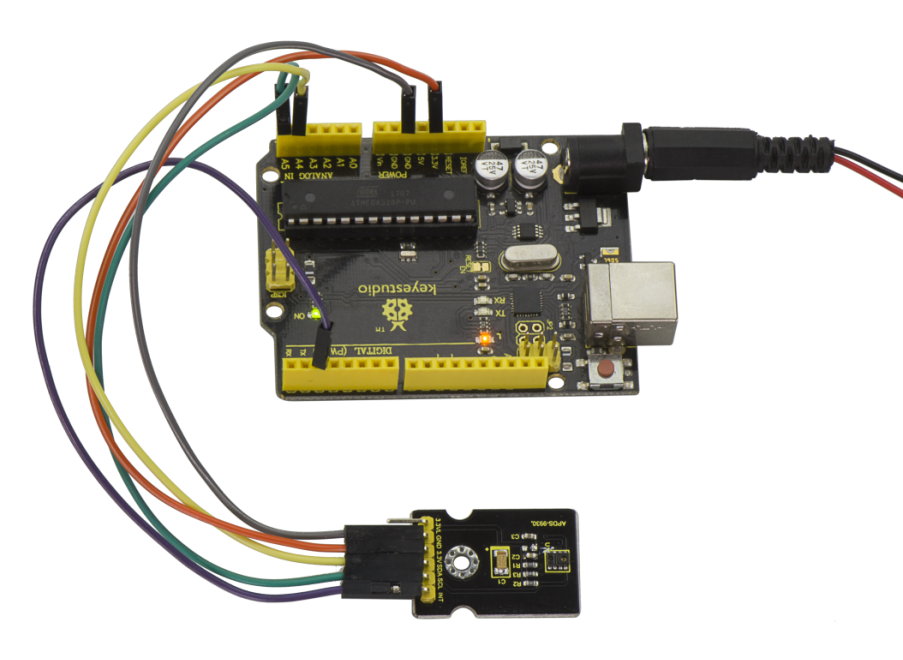

APDS-9930 Attitude Sensor Module |

1 |

|

43 |

ALS Infrared LED Optical Proximity Detection Module |

1 |

|

44 |

MMA8452Q Triaxial Digital Acceleration Tilt Sensor |

1 |

|

45 |

9G Servo Motor |

1 |

|

46 |

HC-SR04 Blue Ultrasonic Sensor |

1 |

|

47 |

0802 LCD module 5V blue screen(with backlight) |

1 |

|

48 |

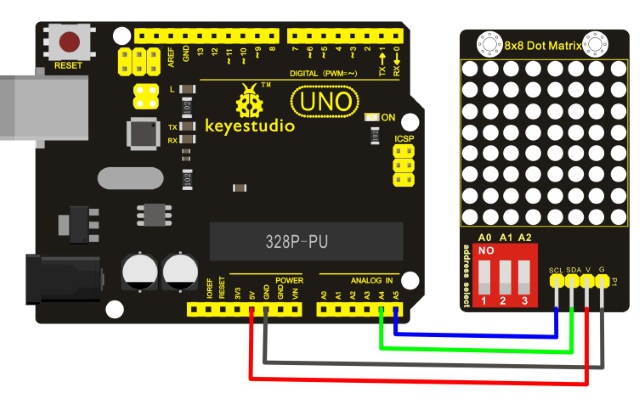

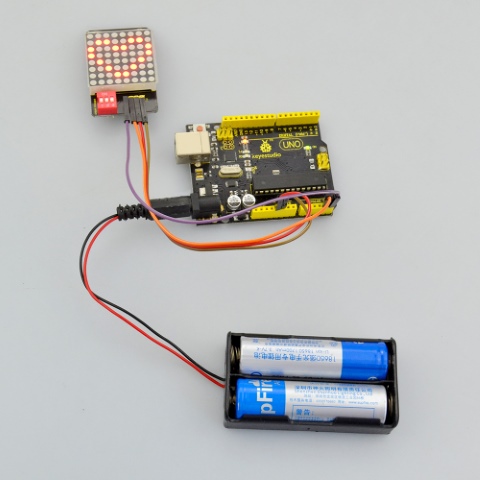

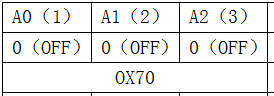

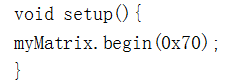

8x8 LED Matrix Module Address Select |

1 |

|

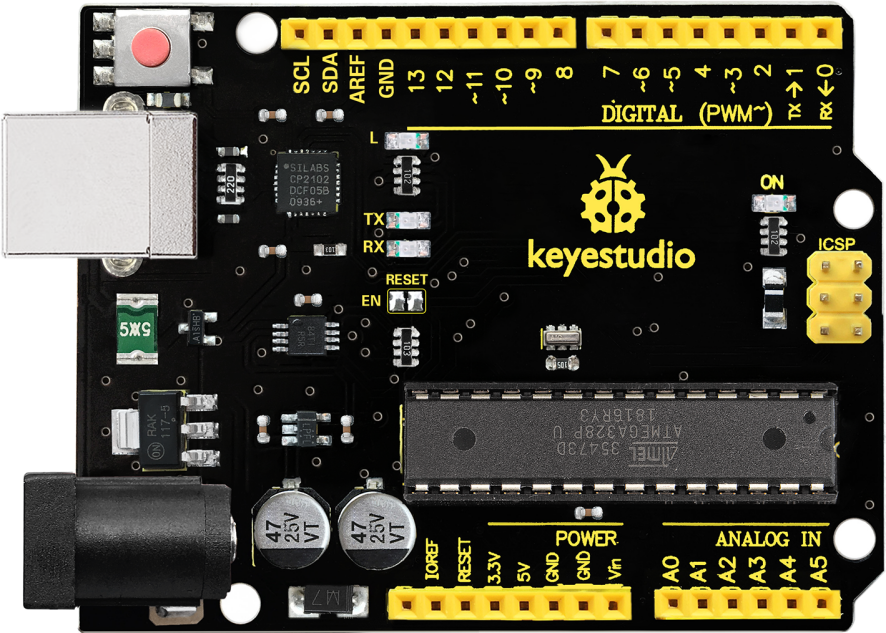

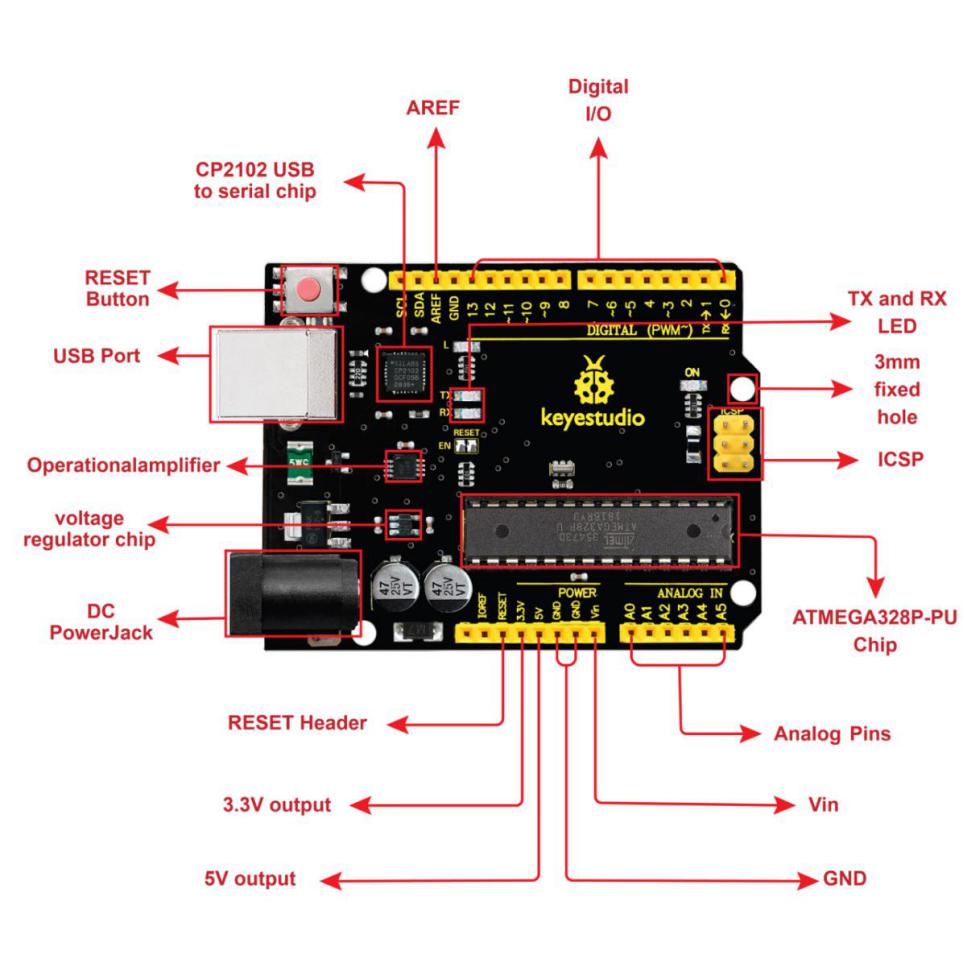

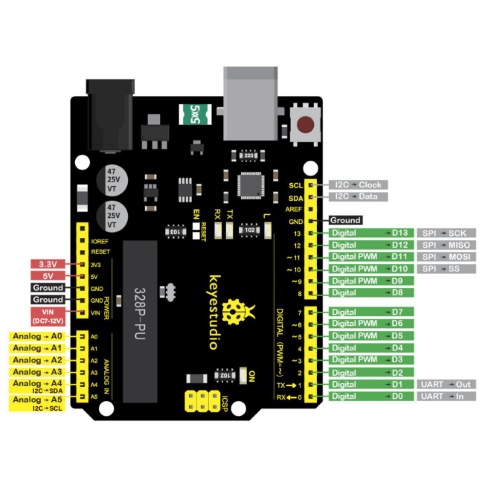

3.keyestudio V4.0 Development Board

Keyestudio V4.0 development board is an Arduino uno-compatible board, which is based on ATmega328P MCU, and with a cp2102 Chip as a UART-to-USB converter.

It has 14 digital input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16 MHz quartz crystal, a USB connection, a power jack, 2 ICSP headers and a reset button.

It contains everything needed to support the micro controller; simply connect it to a computer with a USB cable or power it via an external DC power jack (DC 7-12V) or via female headers Vin/ GND(DC 7-12V) to get started.

It contains everything needed to support the micro controller; simply connect it to a computer with a USB cable or power it via an external DC power jack (DC 7-12V) or via female headers Vin/ GND(DC 7-12V) to get started.

Microcontroller |

ATmega328P-PU |

|---|---|

Operating Voltage |

5V |

Input Voltage (recommended) |

DC7-12V |

Digital I/O Pins |

14 (D0-D13) (of which 6 provide PWM output) |

PWM Digital I/O Pins |

6 (D3, D5, D6, D9, D10, D11) |

Analog Input Pins |

6 (A0-A5) |

DC Current per I/O Pin |

20 mA |

DC Current for 3.3V Pin |

50 mA |

Flash Memory |

32 KB (ATmega328P-PU) of which 0.5 KB used by bootloader |

SRAM |

2 KB (ATmega328P-PU) |

EEPROM |

1 KB (ATmega328P-PU) |

Clock Speed |

16 MHz |

LED_BUILTIN |

D13 |

4.Install Arduino IDE and Driver

Click the link to start learning how to download software, install drivers, upload code, and install library files.

5.Projects

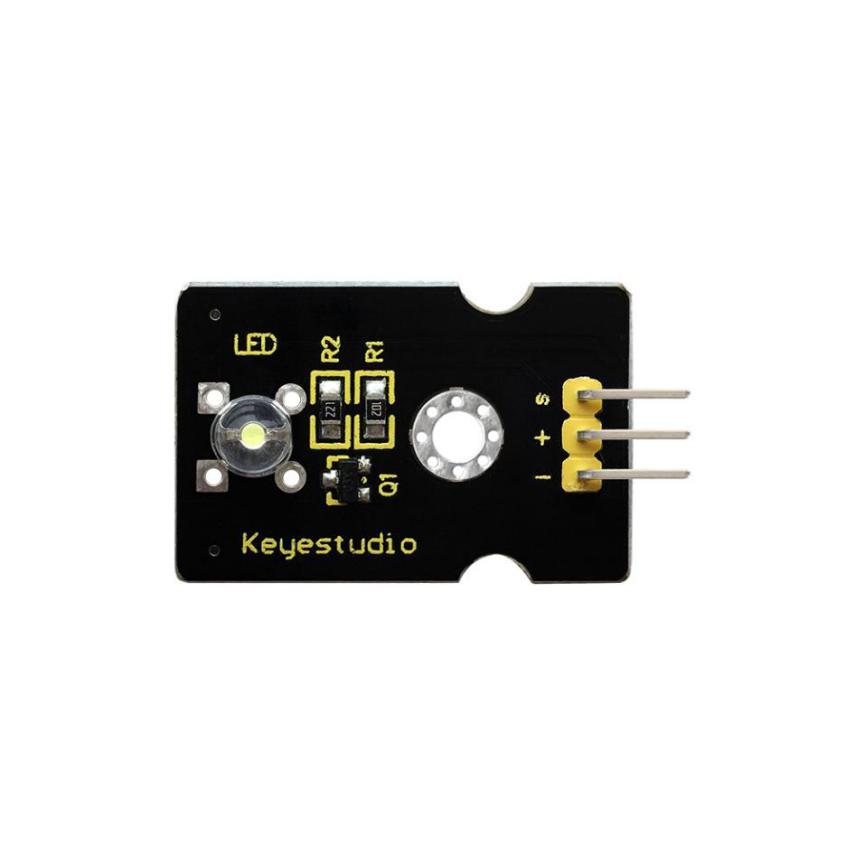

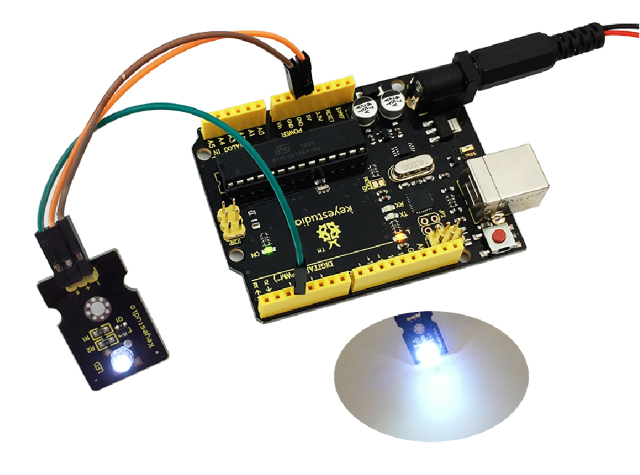

Project 1: White LED

Description

This white LED light module is ideal for Arduino starters. It can be easily connected to IO/Sensor shield. It enables interaction with light-related works.

Note: You can choose other LED modules to emit different color like yellow, red, green and blue.

Specification

White LED module

Type: Digital

PH2.54 socket

Size: 30*20mm

Weight: 3g

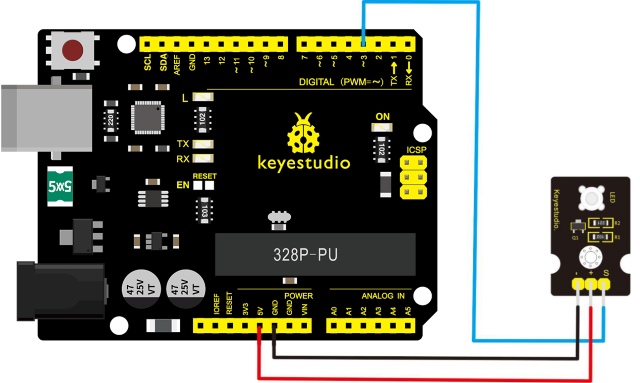

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 board*1

White LED module *1

USB Cable*1

Jumper wire*3

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

int buzzPin =3; //Connect Buzzer on Digital Pin3

void setup()

{

pinMode(buzzPin, OUTPUT);

}

void loop()

{

digitalWrite(buzzPin, HIGH);

delay(1);

digitalWrite(buzzPin, LOW);

delay(1);

}

Example Result

Done wiring and powered up, upload well the code, you will see the LED module emit the white light.

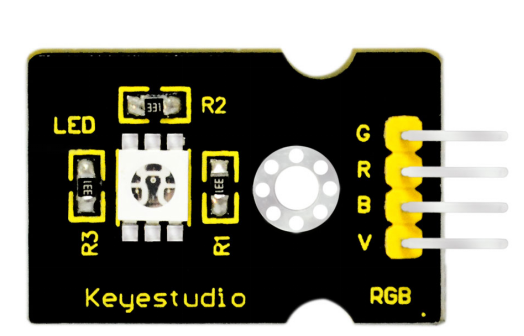

Project 2: RGB LED

Description

This is a full-color LED module, which contains 3 basic colors-red, green and blue. They can be seen as separate LED lights.

After programming, you can turn them on and off by sequence or can also use PWM analog output to mix three colors to generate different colors.

Specification

Color: red, green and blue

Brightness: High

Voltage: 5V

Input: digital level

Size: 30 *20mm

Weight: 3g

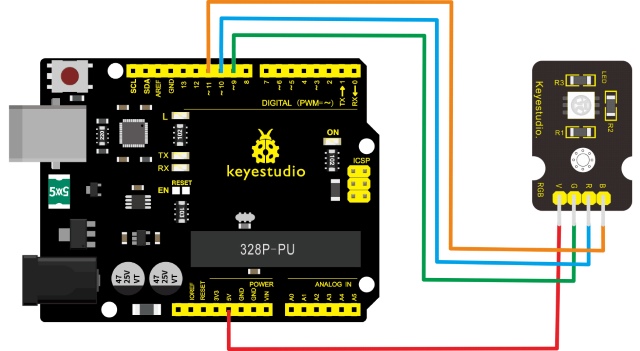

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

RGB LED module *1

USB Cable*1

Jumper Wire*4

Connect the V pin of module to 5V port of V4.0 board, connect the B pin to Digital 11, R pin to Digital 10, G pin to Digital 9.

Sample Code

Copy and paste the below code to Arduino software.

///////////////////////////////////////////////////////////

int redpin = 11; //select the pin for the red LED

int bluepin =10; // select the pin for the blue LED

int greenpin =9;// select the pin for the green LED

int val;

void setup() {

pinMode(redpin, OUTPUT);

pinMode(bluepin, OUTPUT);

pinMode(greenpin, OUTPUT);

}

void loop()

{for(val=255; val>0; val--)

{analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

for(val=0; val<255; val++)

{analogWrite(11, val);

analogWrite(10, 255-val);

analogWrite(9, 128-val);

delay(1);

}

}

///////////////////////////////////////////////////////////

Example Result

Done wiring and powered up, upload well the code, you will see the RGB LED module emit shiny colors.

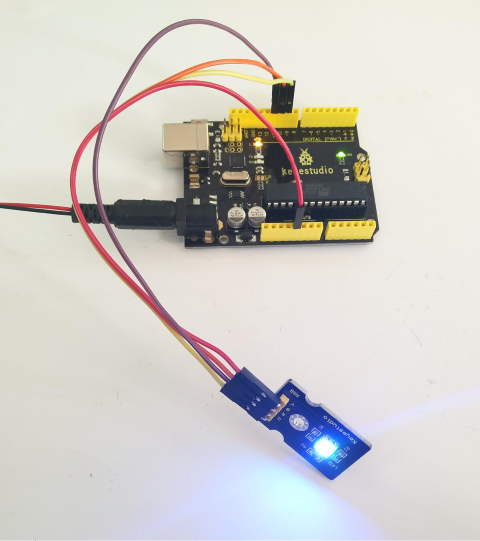

Project 3: 3W LED

Description

This LED module is of high brightness because the lamp beads it carries is 3w. You can apply this module to Arduino projects, ideal for Robot or search and rescue platform application.

For example, intelligent robots can use this module for illumination purpose. Please note that the LED light can’t be exposed directly to human eyes for safety concerns.

Specification

Color temperature: 6000~7000K

Luminous flux: 180~210lm

Current: 700~750mA

Power: 3W

Light angle: 140 degree

Working temperature: -50~80℃

Storage temperature: -50~100℃

High power LED module, controlled by IO port microcontroller

IO Type: Digital

Supply Voltage: 3.3V to 5V

Size: 40x28mm

Weight: 6g

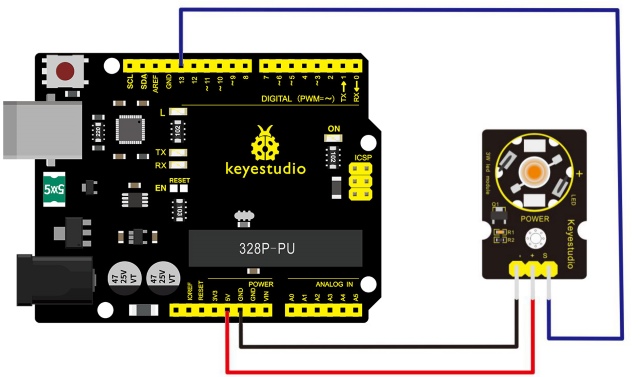

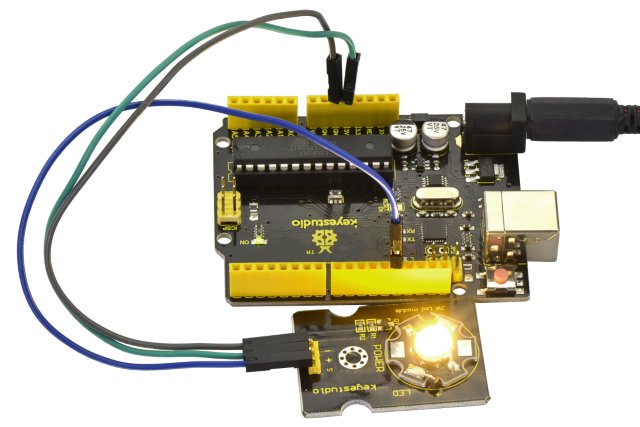

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

3W LED module *1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 13 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

///////////////////////////////////////////////////////////

// the setup function runs once when you press reset or power the board

void setup() {

// initialize digital pin 13 as an output.

pinMode(13, OUTPUT);

}

// the loop function runs over and over again forever

void loop() {

digitalWrite(13, HIGH); // turn the LED on (HIGH is the voltage level)

delay(1000); // wait for a second

digitalWrite(13, LOW); // turn the LED off by making the voltage LOW

delay(1000); // wait for a second

}

///////////////////////////////////////////////////////////

Example Result

Done wiring and powered up, upload well the code, both D13 led and the led on the module blink for one second then off, circularly.

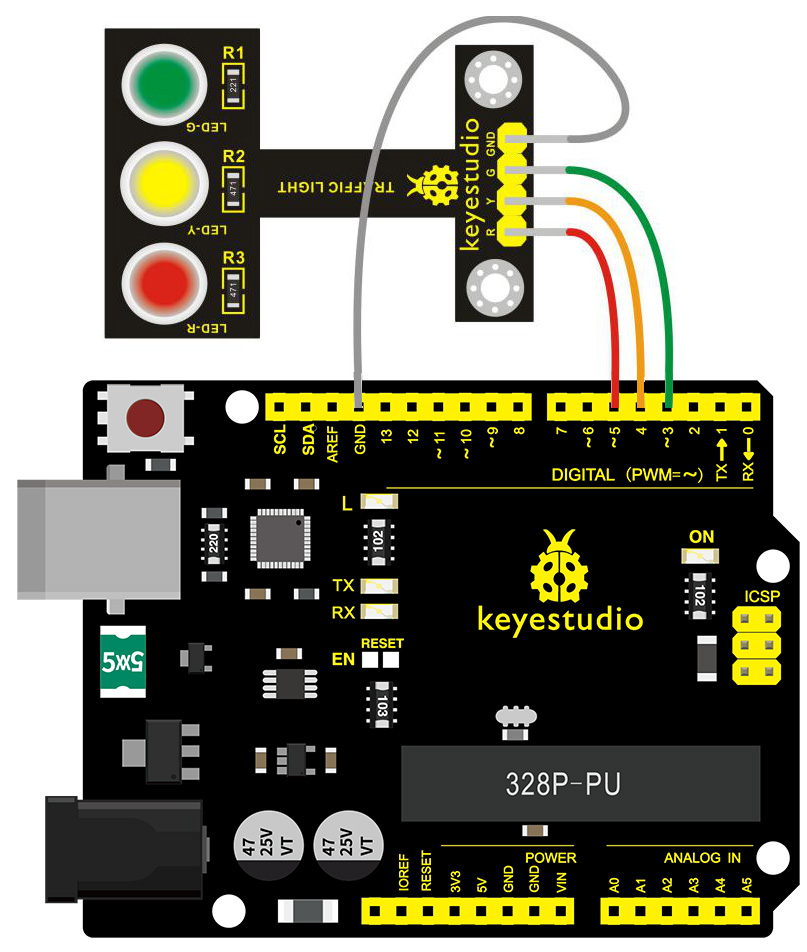

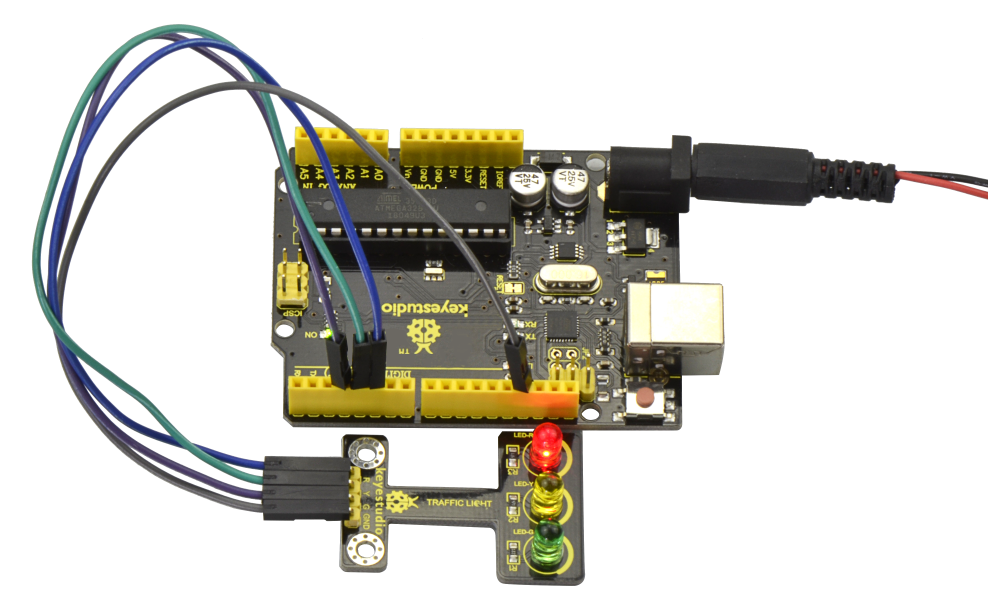

Project 4: Traffic Light

Description

When learning the microcontroller, you may usually use three LEDs, namely red, green and yellow lights to simulate the traffic light blinking via external connection.

This time we specially design this module which is very convenient for wiring, and on the module you can see the red, yellow and green LED.

This module is fully compatible with Arduino microcontroller and Raspberry Pi system.

Specification

Working Voltage: 3.3-5v

Interface Type: digital

PH2.54 Socket

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Traffic light module *1

USB Cable*1

Jumper Wire*4

Connect the R pin of module to Digital 5 of V4.0 board, connect the Y pin to Digital 4, G pin to Digital 3, GND pin to ground port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

int redled =5; // initialize digital pin 5.

int yellowled =4; // initialize digital pin 4.

int greenled =3; // initialize digital pin 3.

void setup()

{

pinMode(redled, OUTPUT);// set the pin with red LED as “output”

pinMode(yellowled, OUTPUT); // set the pin with yellow LED as “output”

pinMode(greenled, OUTPUT); // set the pin with green LED as “output”

}

void loop()

{

digitalWrite(greenled, HIGH);//// turn on green LED

delay(5000);// wait 5 seconds

digitalWrite(greenled, LOW); // turn off green LED

for(int i=0;i<3;i++)// blinks for 3 times

{

delay(500);// wait 0.5 seconds

digitalWrite(yellowled, HIGH);// turn on yellow LED

delay(500);// wait 0.5 seconds

digitalWrite(yellowled, LOW);// turn off yellow LED

}

delay(500);// wait 0.5 seconds

digitalWrite(redled, HIGH);// turn on red LED

delay(5000);// wait 5 seconds

digitalWrite(redled, LOW);// turn off red LED

}

////////////////////////////////////////////////////////////////////

Example Result

Done uploading the code, powered up, three LEDs on the module will automatically simulate the traffic light on and off, circularly.

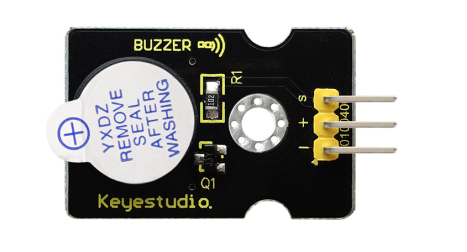

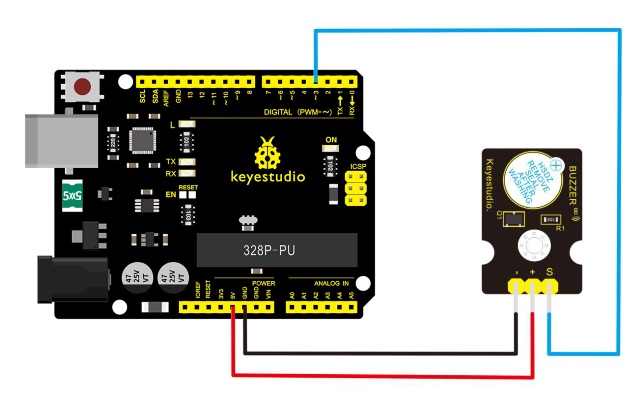

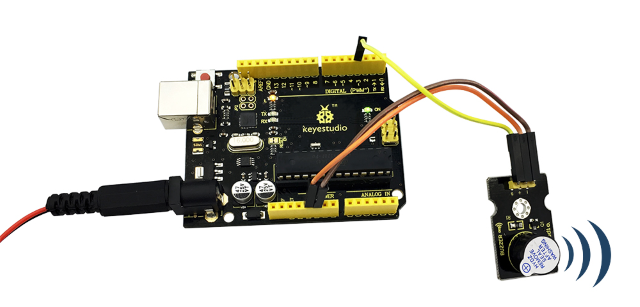

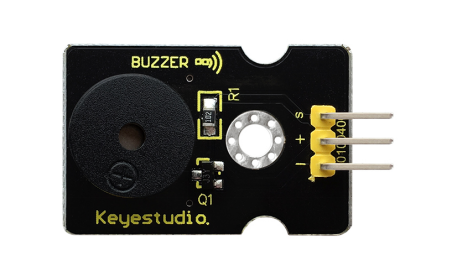

Project 5: Buzzer Beeps

Description

Here is the simplest sound making module. You can use high/low level to drive it. Changing the frequency it buzzes can produce different sounds.

This module is widely used on our daily appliances like PC, refrigerator, phones, etc.

In addition, you can create many interesting interactive projects with this small but useful module. Just try it!! You will find the electronic sound it creates so fascinating.

Specification

Working voltage: 3.3-5v

Interface type: digital

Size: 30*20mm

Weight: 4g

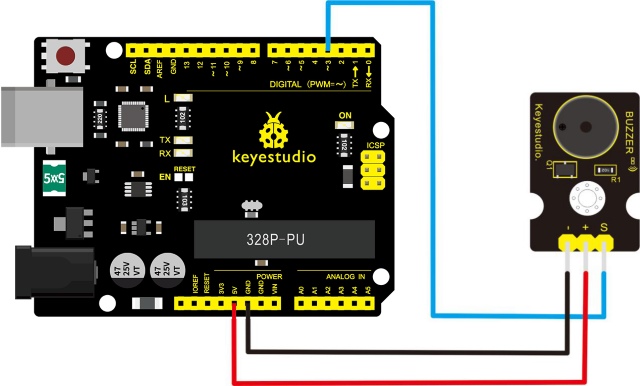

Connection Diagram

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

int buzzPin =3; //Connect Buzzer on Digital Pin3

void setup()

{

pinMode(buzzPin, OUTPUT);

}

void loop()

{

digitalWrite(buzzPin, HIGH);

delay(1);

digitalWrite(buzzPin, LOW);

delay(1);

}

////////////////////////////////////////////////////////////////////

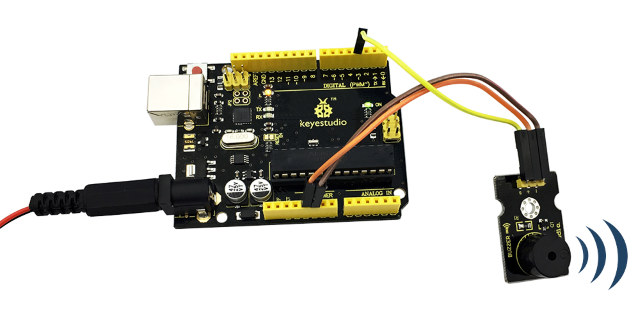

Example Result

Done uploading the code to board, the buzzer will make a sound.

Project 6: Passive Buzzer

Description

We can use Arduino to make many interactive works of which the most commonly used is acoustic-optic display. The circuit in this experiment can produce sound.

Normally, the experiment can be done with a buzzer or a speaker, while buzzer is simpler and easier to use.

The buzzer we introduced here is a passive buzzer. It cannot be actuated by itself, but by external pulse frequencies. Different frequencies produce different sounds. You can use Arduino to code the melody of a song, quite fun and simple.

Specification

Working voltage: 3.3-5v

Interface type: digital

Size: 30*20mm

Weight: 4g

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Passive buzzer module*1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

int buzzer=3;//set digital IO pin of the buzzer

void setup()

{

pinMode(buzzer,OUTPUT);// set digital IO pin pattern, OUTPUT to be output

}

void loop()

{ unsigned char i,j;//define variable

while(1)

{ for(i=0;i<80;i++)// output a frequency sound

{ digitalWrite(buzzer,HIGH);// sound

delay(1);//delay1ms

digitalWrite(buzzer,LOW);//not sound

delay(1);//ms delay

}

for(i=0;i<100;i++)// output a frequency sound

{

digitalWrite(buzzer,HIGH);// sound

digitalWrite(buzzer,LOW);//not sound

delay(2);//2ms delay

}

}

}

////////////////////////////////////////////////////////////////////

Example Result

Done uploading the code to board, the buzzer will make a sound.

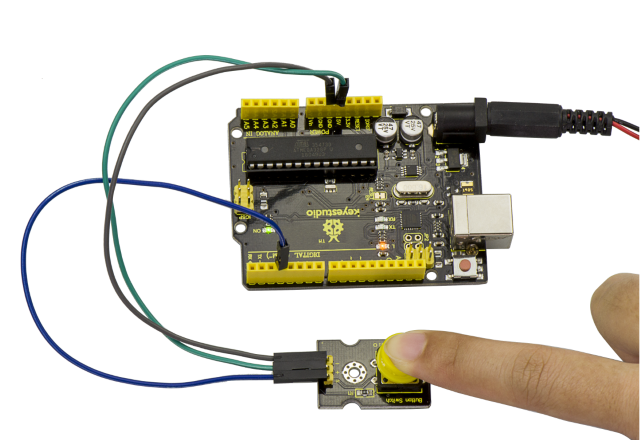

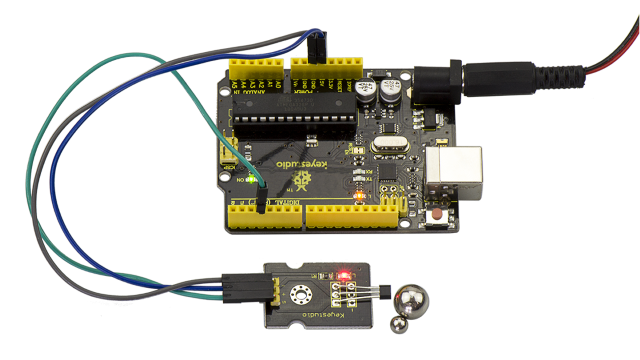

Project 8: Collision Flash

Description

Crash sensor, also known as electronic switch, is a digital on-off input module necessary for elementary electronic learning.

By programming, it can realize to control over light, sound device, key choice function of LCD display, etc.

Using 3P sensor cable to connect it to sensor shield, it can be installed to 4WD AL alloy mobile robot platform to realize collision detection function. It is both convenient and efficient.

You can make a collision flasher using collision module and built-in LED on interface 13. Connect the collision sensor to pin 3. When the collision sensor senses a collision signal, the LEDs on both main board and module will light up simultaneously.

Parameters

If collision happens upfront of where collision module is installed, module outputs low level signal; no collision, outputs high level signal.

Module reserves M3 mounting hole, convenient for fixation on a car.

With switch indicator light, if there is collision, light is on; no collision, light is off.

Pin definition

Positive pin (+): connect to 3v-12v power supply

Negative pin (-): connect to GND

Signal pin (S): connect to High-low level output

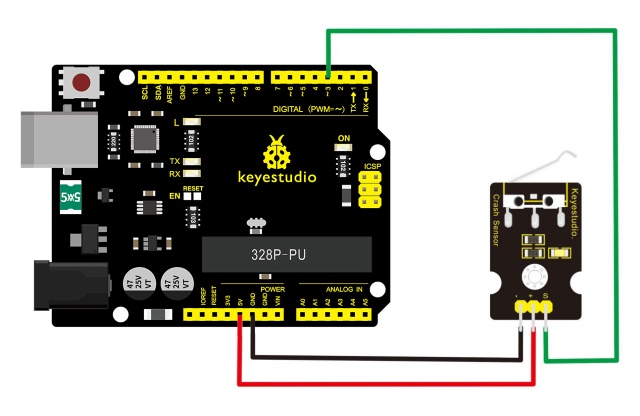

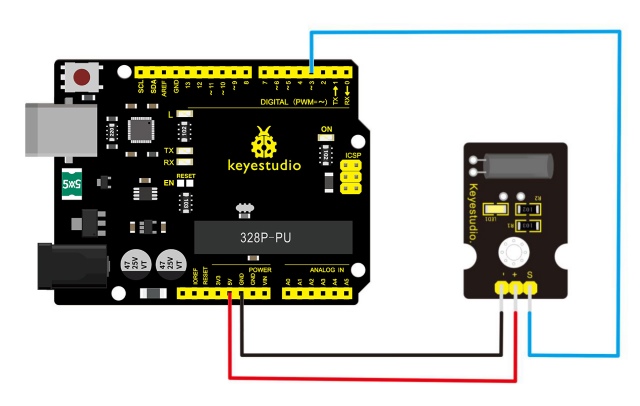

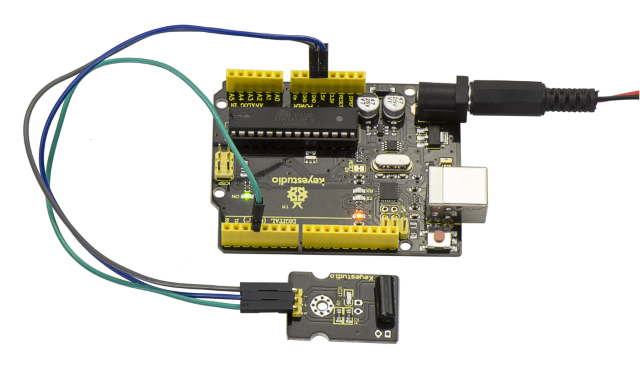

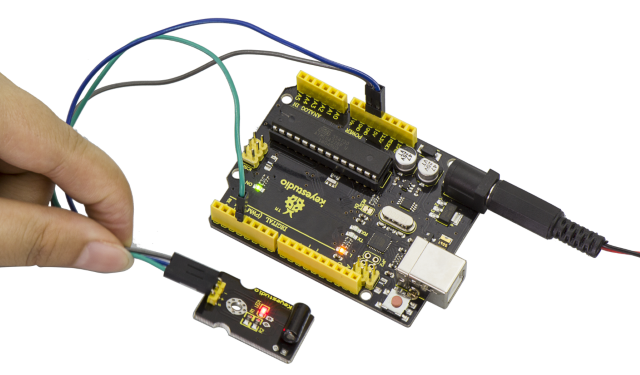

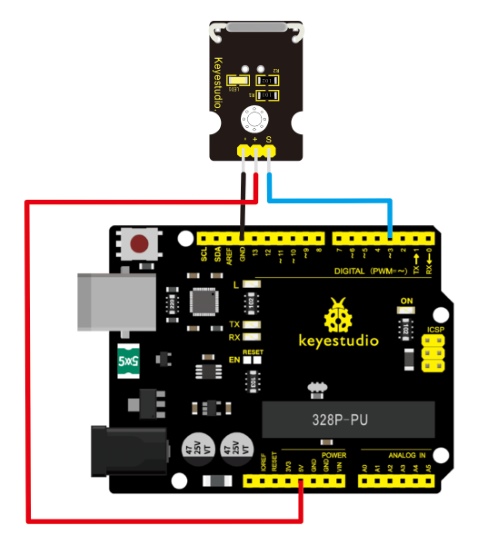

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Crash module *1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

int Led=13;// set pin for LED

int Shock=3// set pin for collision sensor

;int val;// set digital variable val

void setup()

{

pinMode(Led,OUTPUT);// set pin LED as output

pinMode(Shock,INPUT);// set collision sensor as input

}

void loop()

{

val=digitalRead(Shock);// read value on pin 3 and assign it to val

if(val==HIGH)// when collision sensor detects a signal, LED turns on.

{

digitalWrite(Led,LOW);

} else

{

digitalWrite(Led,HIGH);

}

}

////////////////////////////////////////////////////////////////////

Example Result

Wire it up well and then upload the code to the board.

When the object crashes the switch of sensor, both the led on the sensor and led 13 on the board are turned on.

Project 9: Line -tracking Sensor

Description

This Line Tracking Sensor can detect white line in black or black line in white.

The single line-tracking signal provides a stable output signal TTL for a more accurate and more stable line. Multi-channel option can be easily achieved by installing required line-tracking robot sensors.

Specification

Power supply: +5V

Operating current: <10mA

Operating temperature range: 0°C ~ + 50°C

Output interface: 3-wire interface (1 - signal, 2 - power, 3 - power supply negative)

Output Level: TTL level

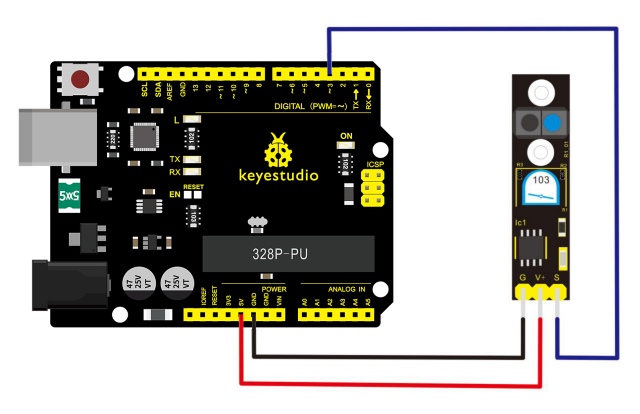

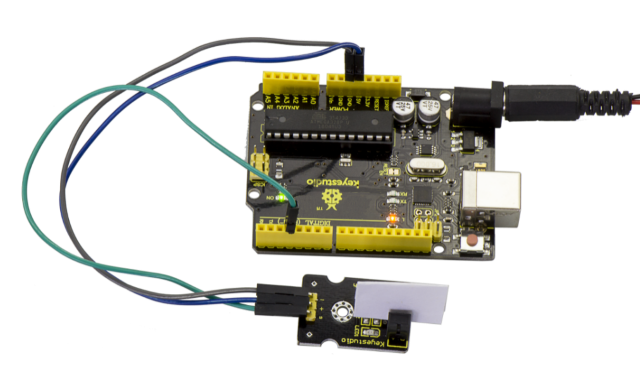

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Line tracking module *1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 3 of V4.0 board, connect the GND pin to GND port, V+ pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

//Arduino Sample Code

void setup()

{

Serial.begin(9600);

}

void loop()

{

Serial.println(digitalRead(3)); // print the data from the sensor

delay(500);

}

////////////////////////////////////////////////////////////////////

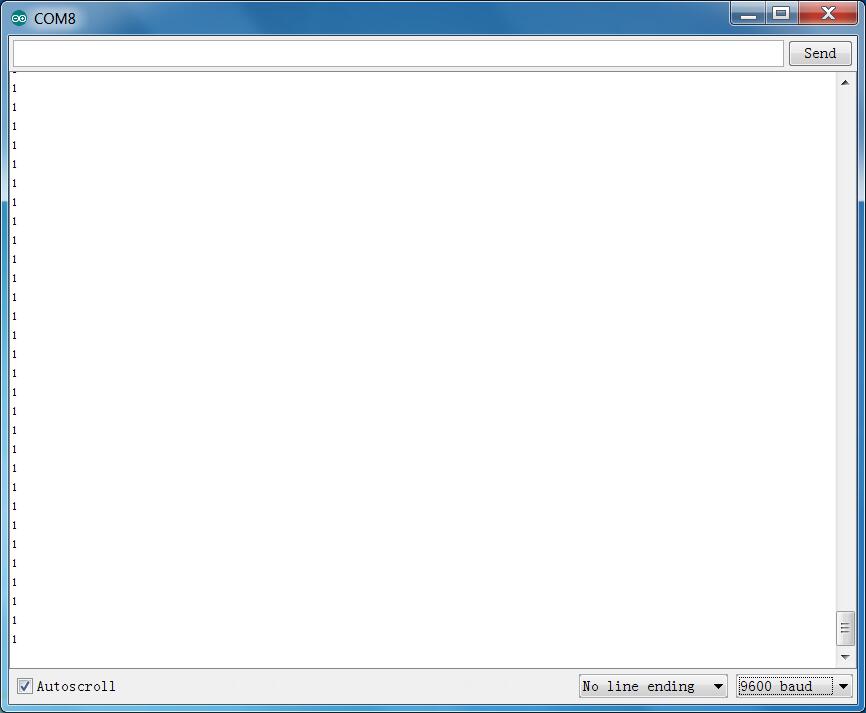

Example Result

Done uploading the code to board, open the serial monitor and set the baud rate as 9600, then you can see the data from the sensor.

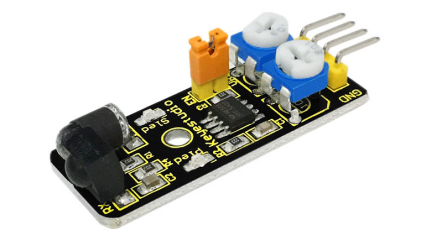

Project 10: Infrared Obstacle Avoidance

Description

Infrared obstacle detector sensor is equipped with distance adjustment function and is especially designed for wheeled robots.

This sensor has strong adaptability to ambient light and is of high precision.

It has a pair of infrared transmitting and receiving tube. When infrared ray launched by the transmitter tube encounters an obstacle (its reflector), the infrared ray will be reflected to the receiver tube, thus the indicator will light up, and signal output interface outputs digital signal.

In addition, you can rotate the potentiometer knob to adjust detection distance (effective distance: 2~40cm, working Voltage: 3.3V-5V ).

Thanks to a wide voltage range, this sensor can work steadily even under fluctuating power supply voltage, and is suitable for various micro-controllers, Arduino controllers and BS2 controllers.

A robot mounted with this sensor can sense obstacle in the environment.

Specification

Working voltage: DC 3.3V-5V

Working current: ≥20mA

Working temperature: -10℃ to+50℃

Detection distance: 2-40cm

IO Interface: 4 wire interfaces (-/+/S/EN)

Output signal: TTL voltage

Accommodation mode: Multi-circle resistance regulation

Effective Angle: 35°

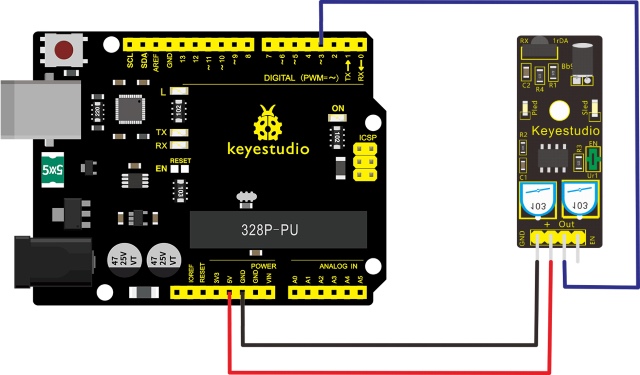

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Obstacle detector module *1

USB Cable*1

Jumper Wire*3

Connect the Out pin of module to Digital 2 of V4.0 board, connect the V+ pin to 5V port, GND pin to GND port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

const int sensorPin = 3; // the number of the sensor pin

const int ledPin = 13; // the number of the LED pin

int sensorState = 0; // variable for reading the sensor status

void setup() {

pinMode(ledPin, OUTPUT);

pinMode(sensorPin, INPUT); }

void loop(){

// read the state of the sensor value:

sensorState = digitalRead(sensorPin);

// if it is, the sensorState is HIGH:

if (sensorState == HIGH) {

digitalWrite(ledPin, HIGH);

}

else {

digitalWrite(ledPin, LOW);

}

}

////////////////////////////////////////////////////////////////////

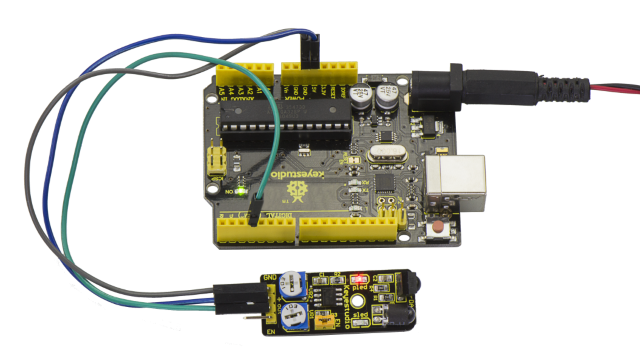

Example Result

Done uploading the code to board, you can see the led on both V4.0 board and obstacle detector sensor is turned on.

If we put a foam block in front of the sensor, this time when sensor detects the obstacle, sled on the sensor will be turned on.

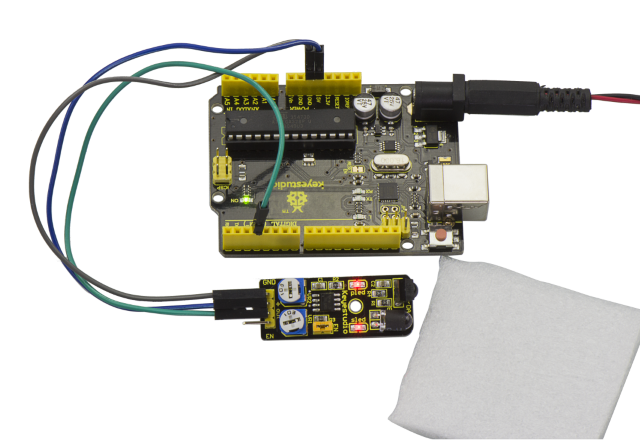

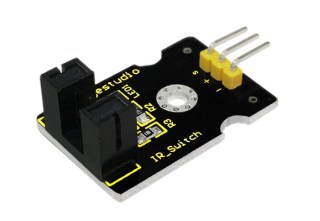

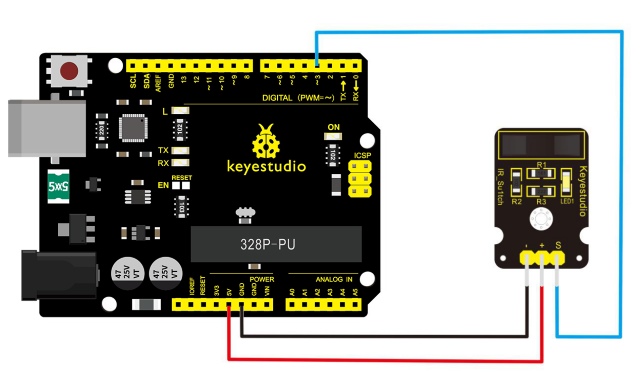

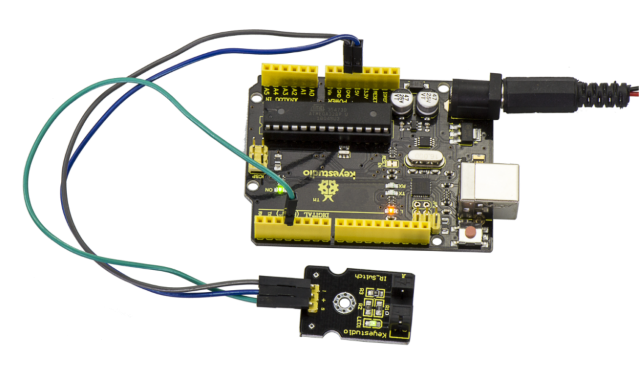

Project 11: Photo Interrupter

Description

Upright part of this sensor is an infrared emitter and on the other side, it’s a shielded infrared detector. By emitting a beam of infrared light from one end to other end, the sensor can detect an object when an object passes through the beam.

It is used for many applications including optical limit switches, pellet dispensing, general object detection, etc.

Specification

Supply Voltage: 3.3V to 5V

Interface: Digital

Size: 30*20mm

Weight: 3g

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Photo interrupter module *1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

// photo interrupter module

int Led = 13 ;// define LED Interface

int buttonpin = 3; // define the photo interrupter sensor interface

int val ;// define numeric variables val

void setup ()

{

pinMode (Led, OUTPUT) ;// define LED as output interface

pinMode (buttonpin, INPUT) ;// define the photo interrupter sensor output interface

}

void loop ()

{

val = digitalRead (buttonpin) ;// digital interface will be assigned a value of 3 to read val

if (val == HIGH) // When the light sensor detects a signal is interrupted, LED flashes

{

digitalWrite (Led, HIGH);

}

else

{

digitalWrite (Led, LOW);

}

}

////////////////////////////////////////////////////////////////////

Example Result

Done uploading the code to board, you can see both led on V4.0 board and on module are turned on. Shown as below.

When pick up a paper on groove joint of module, the signal is interrupted, and led1 on the module will be turned off.

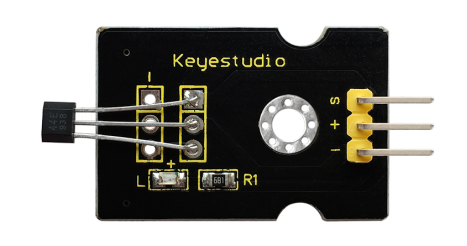

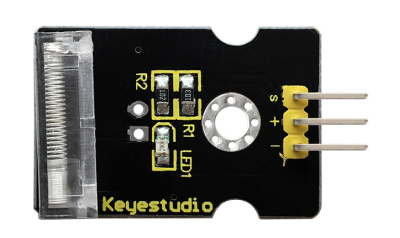

Project 12: Hall Magnetic Sensor

Description

This is a magnetic induction sensor. It can sense the magnetic materials within a detection range up to 3cm. The detection range and the strength of magnetic field are proportional. The output is digital on/off.

This sensor uses the SFE Reed Switch - Magnetic Field Sensor.

Specification

Sensing magnetic materials

Detection range: up to 3cm

Output: digital on/off

Size: 30*20mm

Weight: 3g

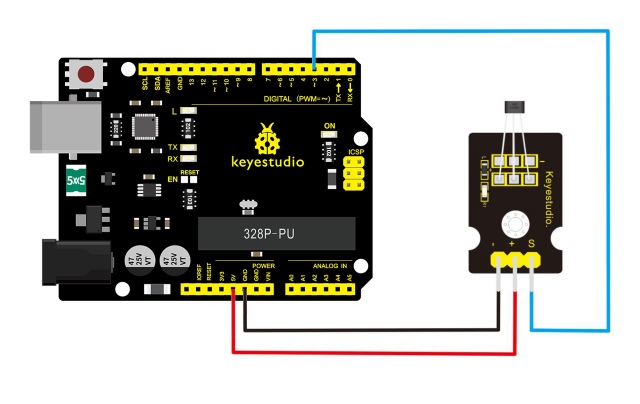

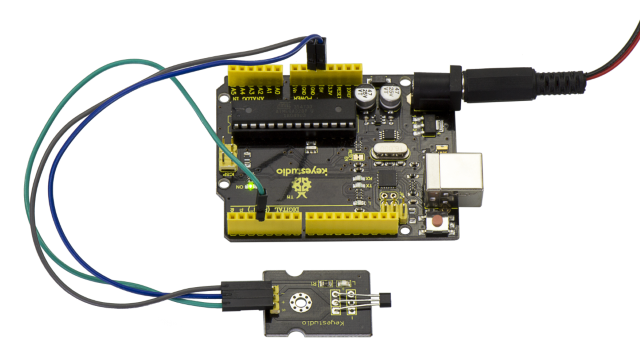

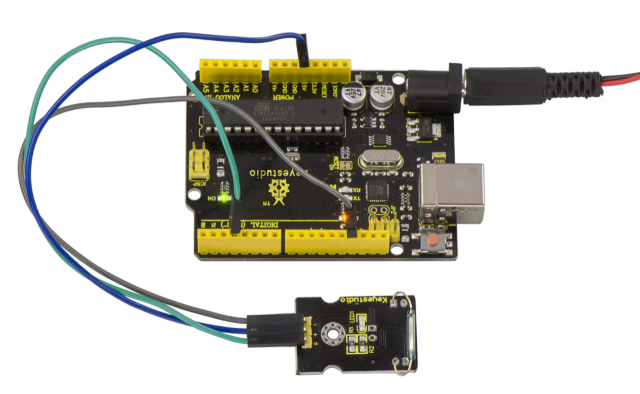

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Hall sensor *1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

int ledPin = 13; // choose the pin for the LED

int inputPin = 3; // Connect sensor to input pin 3

int val = 0; // variable for reading the pin status

void setup() {

pinMode(ledPin, OUTPUT); // declare LED as output

pinMode(inputPin, INPUT); // declare push button as input

}

void loop(){

val = digitalRead(inputPin); // read input value

if (val == HIGH) { // check if the input is HIGH

digitalWrite(ledPin, LOW); // turn LED OFF

} else {

digitalWrite(ledPin, HIGH); // turn LED ON

}

}

////////////////////////////////////////////////////////////////////

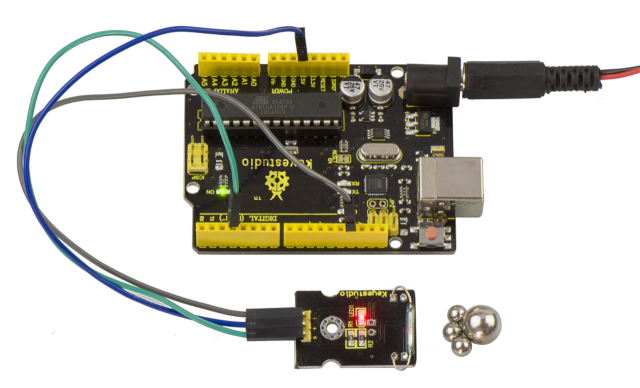

Example Result

Wire it up and upload well the code to board, you will see that D13 indicator on V4.0 board is off, and led on the module is also off.

But if put a magnetic ball close to the hall module, you will see the D13 indicator on V4.0 board is turned on, and led on the module is also turned on.

Project 13: Knock Sensor

Description

This module is a knock sensor. When you knock it, it can send a momentary signal.

You can combine it with Arduino to make some interesting experiments, e.g. electronic drum

Specification

Working voltage: 5V

Size: 30*20mm

Weight: 3g

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Knock sensor *1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

int Led=13;//define LED interface

int Shock=3;//define knock sensor interface

int val;//define digital variable val

void setup()

{

pinMode(Led,OUTPUT);//define LED to be output interface

pinMode(Shock,INPUT);//define knock sensor to be output interface

}

void loop()

{

val=digitalRead(Shock);//read the value of interface3 and evaluate it to val

if(val==HIGH)//when the knock sensor detect a signal, LED will be flashing

{

digitalWrite(Led,LOW);

}

else

{

digitalWrite(Led,HIGH);

}

}

////////////////////////////////////////////////////////////////////

Example Result

Done wiring and powered up as above, upload well the code, then knock at the sensor, you will see both D13 led on the V4.0 board and D1 led on the sensor are turned on.

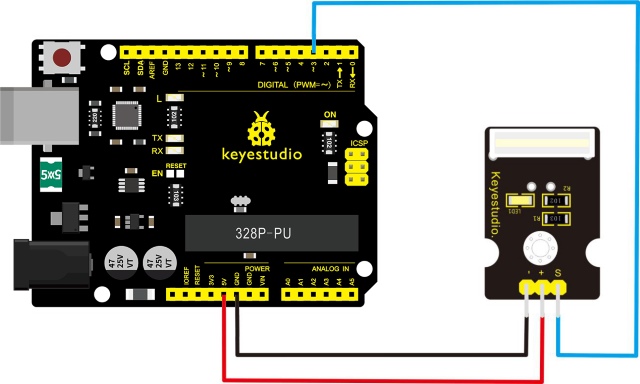

Project 14: Digital Tilt Switch

Description

Tilt Sensor is a digital tilt switch. It can be used as a simple tilt switch.

Simply plug it to our IO/Sensor shield, easy for wire connection. With dedicated sensor shield and Arduino, you can make lots of interesting and interactive works.

Specification

Supply Voltage: 3.3V to 5V

Interface: Digital

Size: 30*20mm

Weight: 3g

Connection Diagram

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

int Led=13;//define LED interface

int Shock=3;//define knock sensor interface

int val;//define digital variable val

void setup()

{

pinMode(Led,OUTPUT);//define LED to be output interface

pinMode(Shock,INPUT);//define knock sensor to be output interface

}

void loop()

{

val=digitalRead(Shock);//read the value of interface3 and evaluate it to val

if(val==HIGH)//when the knock sensor detect a signal, LED will be flashing

{

digitalWrite(Led,LOW);

}

else

{

digitalWrite(Led,HIGH);

}

}

Example Result

Done wiring and powered up, then upload well the code to V4.0 board.

Then tilt the sensor, you will see the led on the sensor is turned on. Shown as below.

Project 15: Capacitive Touch

Description

Are you tired of clicking mechanic buttons? Well, try our capacitive touch sensor. You can find touch sensors mostly used on electronic device. So upgrade your Arduino project with this touch sensor to make it more cool.

This little sensor can sense the touch of body and metal with feedback of a high/low voltage level. Even isolated by some cloth and papers, it can still feel the touch. But its sensitivity will decrease as isolation layer gets thicker.

We will make further improvement on those sensor modules to give you better experience.

Specification

Supply Voltage: 3.3V to 5V

Interface: Digital

Size: 30*20mm

Weight: 3g

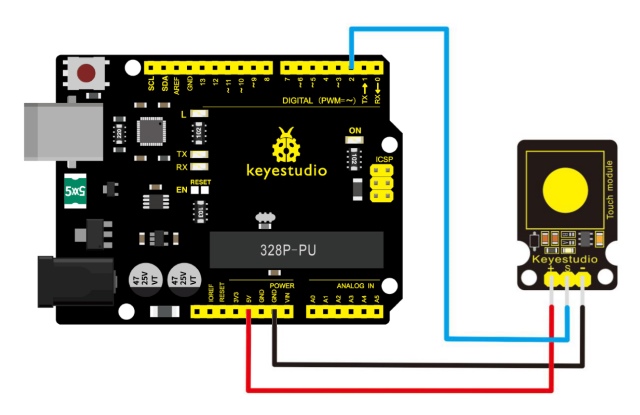

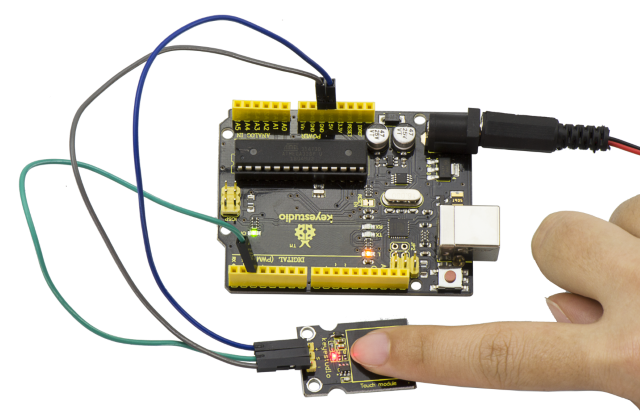

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Capacitive touch sensor*1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 2 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

int ledPin = 13; // Connect LED to pin 13

int switcher = 3; // Connect Tilt sensor to Pin3

void setup()

{

pinMode(ledPin, OUTPUT); // Set digital pin 13 to output mode

pinMode(switcher, INPUT); // Set digital pin 3 to input mode

}

void loop()

{

if(digitalRead(switcher)==HIGH) //Read sensor value

{

digitalWrite(ledPin, HIGH); // Turn on LED when the sensor is tilted

}

else

{

digitalWrite(ledPin, LOW); // Turn off LED when the sensor is not triggered

}

}

////////////////////////////////////////////////////////////////////

Example Result

Done wiring and powered up, upload well the code, then touch the sensor with your finger, both D2 led on the sensor and D13 indicator on V4.0 board are on. Otherwise, those two indicators are turned off.

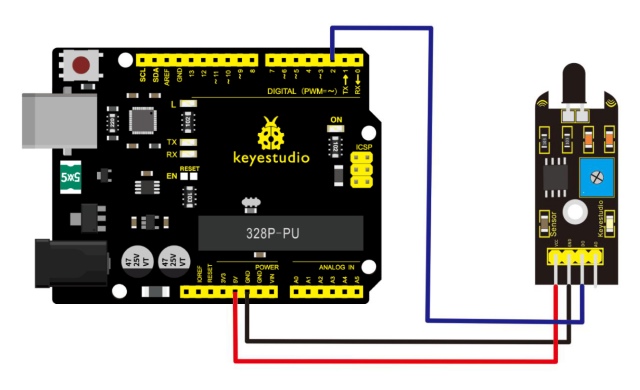

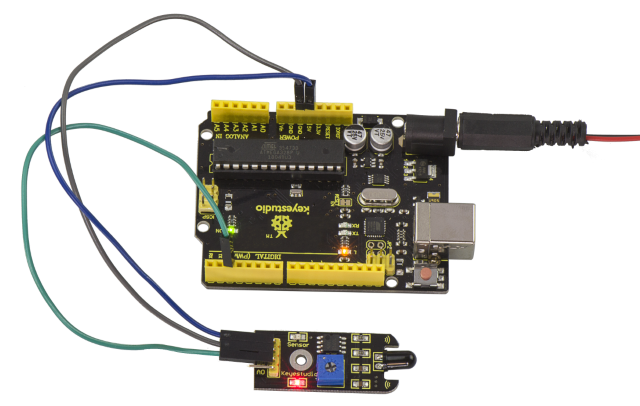

Project 16: Flame Alarm

Description

This flame sensor can be used to detect fire or other lights with wavelength stands at 760nm ~ 1100nm.

In the fire-fighting robot game, the flame plays an important role in the probing, which can be used as the robot’s eyes to find fire source.

Specification

Supply Voltage: 3.3V to 5V

Detection range: 20cm (4.8V) ~ 100cm (1V)

Rang of Spectral Bandwidth: 760nm to 1100nm

Operating temperature: -25℃to 85℃

Interface: digital

Size: 44*16.7mm

Weight: 4g

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Flame sensor*1

USB Cable*1

Jumper Wire*3

Connect the D0 pin of module to Digital 2 of V4.0 board, connect the GND pin to GND port, VCC pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

const int flamePin = 2; // the number of the flame pin

const int ledPin = 13; // the number of the LED pin

// variables will change:

int State = 0; // variable for reading status

void setup() {

// initialize the LED pin as an output:

pinMode(ledPin, OUTPUT);

// initialize the pushbutton pin as an input:

pinMode(flamePin, INPUT);

}

void loop(){

// read the state of the value:

State = digitalRead(flamePin);

if (State == HIGH) {

// turn LED on:

digitalWrite(ledPin, HIGH);

}

else {

// turn LED off:

digitalWrite(ledPin, LOW);

}

}

////////////////////////////////////////////////////////////////////

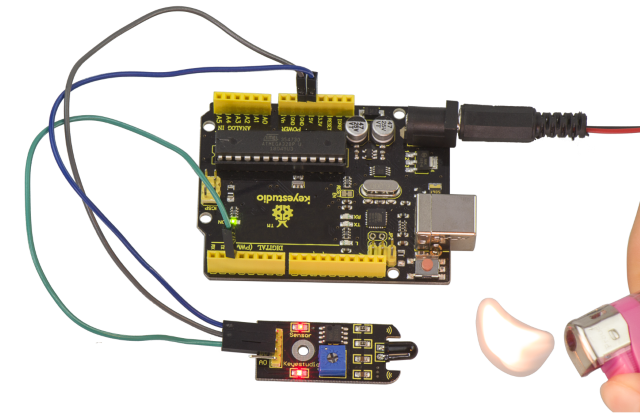

Example Result

Done wiring and powered up, upload well the code to the board.

Then if you put a lighter close to the sensor, when the sensor detects the flame, another led on the sensor is turned on.

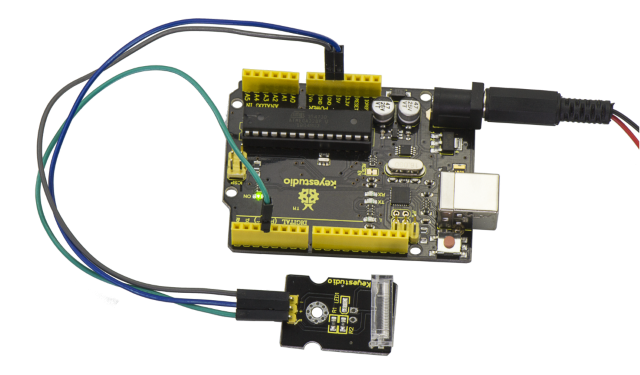

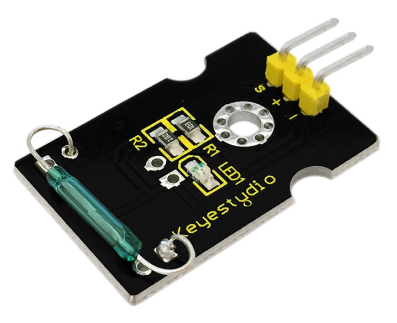

Project 17: Reed Switch

Description

Reed Switch is a special switch and a main component for reed relay and proximity switch.

Reed switch is usually comprised of two soft magnetic materials and metal reed contacts which will disconnect itself when there is no magnetic.

In addition, some reed switches are also equipped with another reed acting as the third normally-closed contact. These reed contacts are encapsulated in a glass tube full of inert gases(such as nitrogen and helium) or in a vacuum glass tube.

The reeds encapsulated in the glass tube are placed in parallel with ends overlapped. Certain amount of space or mutual contact will be reserved to constitute the normally-open or normally-closed contacts of the switch.

Reed switch can be used as for count, limit or other purposes.

For instance, a kind of bike-kilometer is constituted by sticking magnetic to the tire and mounting reed switch aside.

You can also mount reed switch on the door for alarming purpose or as switches.

Reed switch has been widely applied in household appliances, cars, communication, industry, healthcare and security areas.

Furthermore, it can also be applied to other sensors and electric devices such as liquidometer, door magnet, reed relay, oil level sensor and proximity sensor(magnetic sensor). It can be used under high-risk environment.

Specification

Working voltage: DC 3.3V-5V

Working current: ≥20mA

Working temperature: -10℃ to +50℃

Detection distance: ≤10mm

IO Interface: 3 wire interfaces (-/+/S)

Size: 30*20mm

Weight: 3g

Connection Diagram

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

int Led=13;//define LED interface

int buttonpin=3; //define magnetic ring sensor interface

int val;//define digital variable val

void setup()

{

pinMode(Led,OUTPUT);//define LED as output interface

pinMode(buttonpin,INPUT);//define magnetic ring sensor as output interface

}

void loop()

{

val=digitalRead(buttonpin);// read and assign the value of digital interface 3 to val

if(val==HIGH)//When a signal is detected by magnetic ring sensor, LED will flash

{

digitalWrite(Led,HIGH);

}

else

{

digitalWrite(Led,LOW);

}

}

////////////////////////////////////////////////////////////////////

Example Result

Done wiring and powered up, upload well the code to the board. You can see the D13 led on V4.0 board is on.

Then we put some magnetic balls close to the sensor. When the sensor detects the magnetic field signal, the led on the sensor will be turned on but D13 led will be turned off.

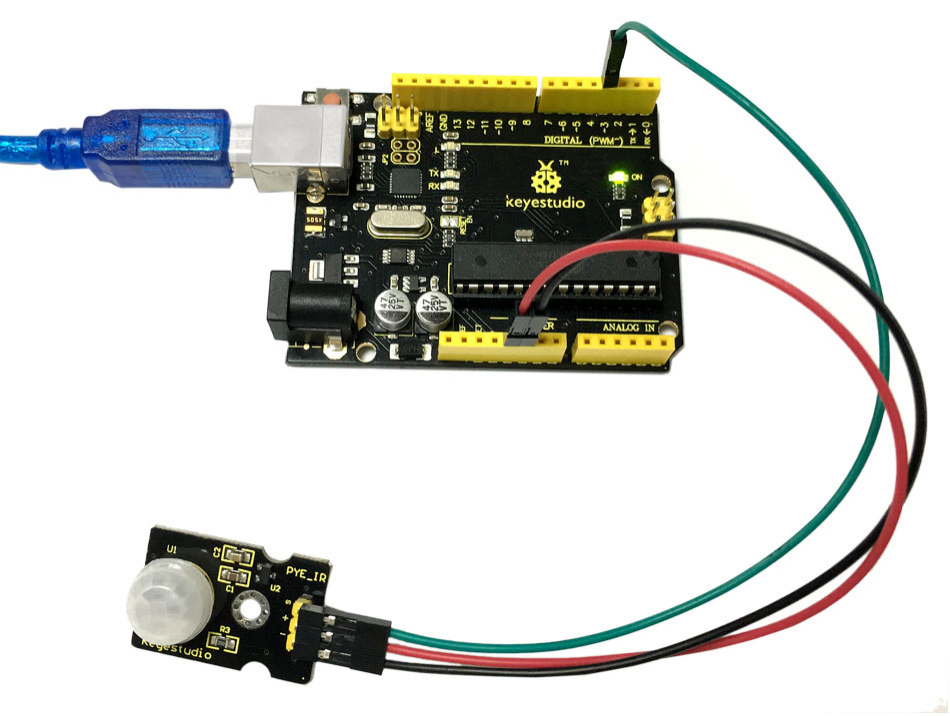

Project 18: PIR Motion Sensor

Description

Pyroelectric infrared motion sensor can detect infrared signals from a moving person or moving animal, and output switching signals.

It can be applied to a variety of occasions to detect the movement of human body.

Conventional pyroelectric infrared sensors require body pyroelectric infrared detector, professional chip and complex peripheral circuit, so the size is much more bigger, with complex circuit and lower reliability.

Now we launch this new pyroelectric infrared motion sensor, specially designed for Arduino.

It uses an integrated digital body pyroelectric infrared sensor, with smaller size, higher reliability, lower power consumption and simpler peripheral circuit.

Specification

Input Voltage: 3.3 ~ 5V, Maximum for 6V

Working Current: 15uA

Working Temperature: -20 ~ 85 ℃

Output Voltage: High 3V, Low 0V

Output Delay Time (High Level): About 2.3 to 3 Seconds

Detection Angle: 100 °

Detection Distance: 7 meters

Output Indicator LED (if output HIGH, it will be ON)

Limit Current for Pin: 100mA

Size: 30*20mm

Weight: 4g

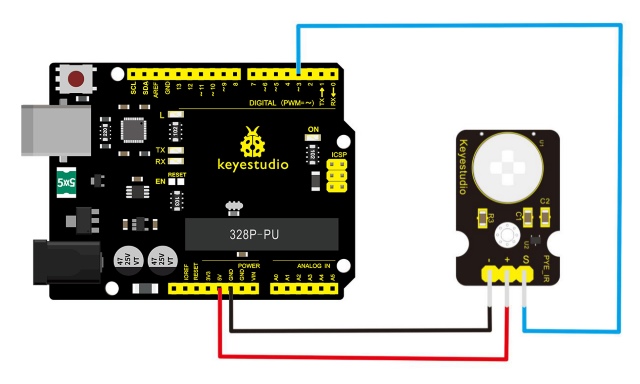

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

PIR motion sensor*1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

byte sensorPin = 3;

byte indicator = 13;

void setup()

{

pinMode(sensorPin,INPUT);

pinMode(indicator,OUTPUT);

Serial.begin(9600);

}

void loop()

{

byte state = digitalRead(sensorPin);

digitalWrite(indicator,state);

if(state == 1)Serial.println("Somebody is in this area!");

else if(state == 0)Serial.println("No one!");

delay(500);

}

////////////////////////////////////////////////////////////////////

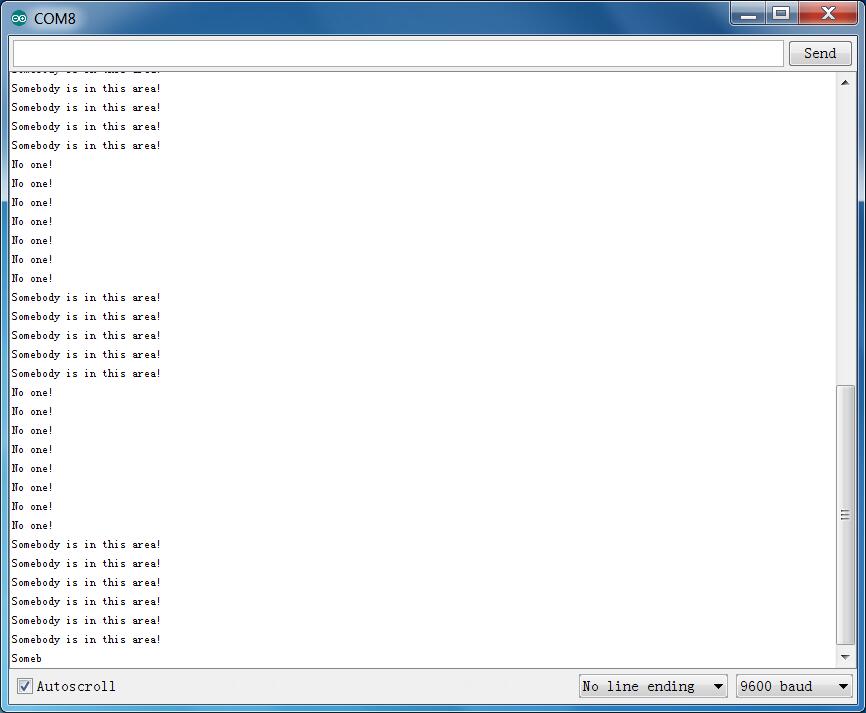

Example Result

Done wiring and powered up, upload well the code, if the sensor detects someone moving nearby, D13 indicator on V4.0 board will light up, and “Somebody is in this area!” is displayed on the serial monitor of Arduino software.

If no detecting the movement, D13 indicator on V4.0 board will be off, and “No one!” is displayed on the serial monitor.

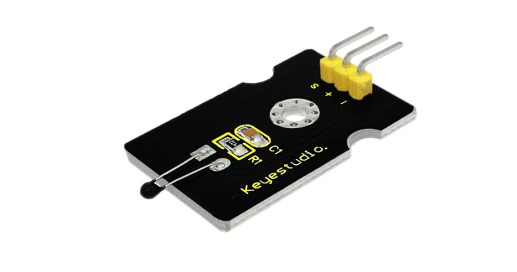

Project 19: Analog Temperature

Description

This module is based on the working principle of a thermistor (resistance varies with temperature change in the environment).

It can sense temperature changes in the surrounding and send the data to the analog IO of Arduino board.

All we need to do is to convert the sensor’s output data into degrees Celsius temperature via simple programming, finally displaying it on the monitor.

It’s both convenient and effective, thus it is widely applied to gardening, home alarm system and other devices.

Specification

Interface type: analog

Working voltage: 5V

Temperature range: -55℃~315℃

Size: 30*20mm

Weight: 3g

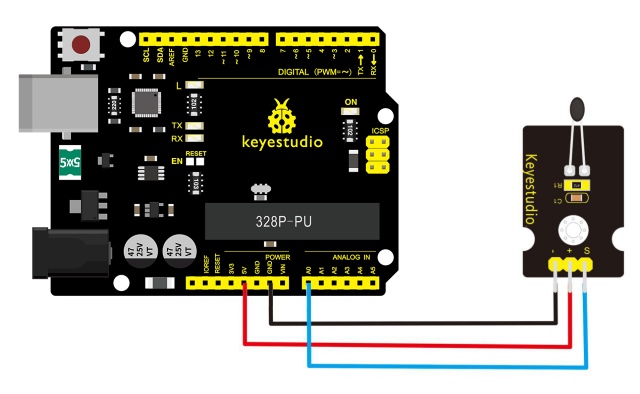

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 Board*1

Analog temperature sensor*1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

void setup()

{Serial.begin(9600);

}

// the loop routine runs over and over again forever:

void loop()

{int sensorValue = analogRead(A0);

Serial.println(sensorValue);

delay(1); }

////////////////////////////////////////////////////////////////////

The above code is only for analog value.

You can see that the analog value is changing according to the temperature change in the environment. But it’s not very obvious.

Let’s solve this by using the following equation. Then upload the code below to the Arduino board. The value read from the serial port is similar to normal temperature. eg. The temperature right now is 30°C.

////////////////////////////////////////////////////////////////////

#include <math.h>

void setup()

{

Serial.begin(9600);

}

void loop()

{

double val=analogRead(0);

double fenya=(val/1023)*5;

double r=(5-fenya)/fenya*4700;

Serial.println( 1/( log(r/10000) /3950 + 1/(25+273.15))-273.15);

delay(1000);

}

////////////////////////////////////////////////////////////////////

Example Result

Done wiring and powered up as the above figure, upload well the code to the board, then open the serial monitor of Arduino IDE, you will see the current temperature value.

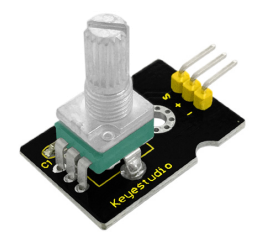

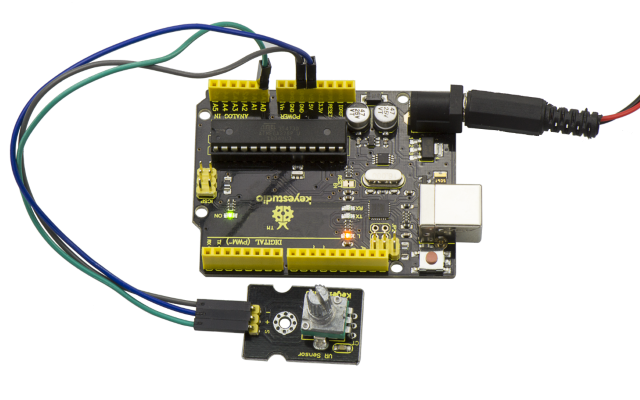

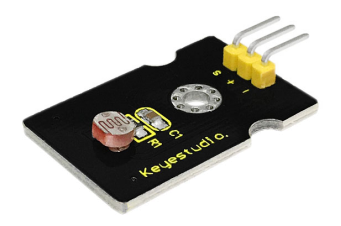

Project 20: Analog Rotation

Description

This analog rotation sensor is Arduino compatible. It is based on a potentiometer. Its voltage can be subdivided into 1024, easy to be connected to Arduino with our sensor shield.

Combined with other sensors, you can use it to make interesting projects by reading the analog value from the IO port.

Specification

Supply Voltage: 3.3V to 5V

Interface: Analog

Size: 30*20mm

Weight: 8g

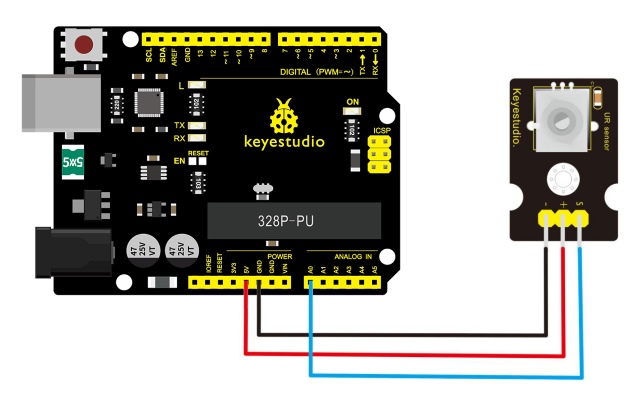

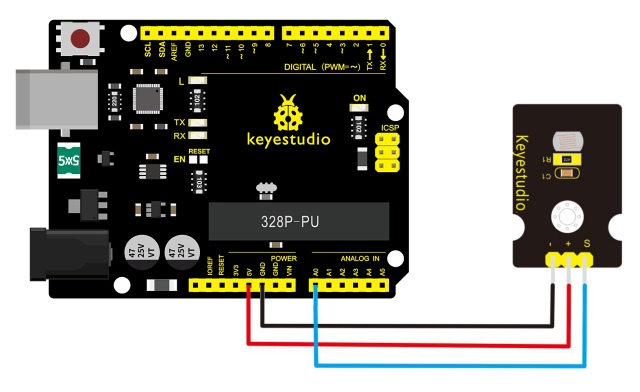

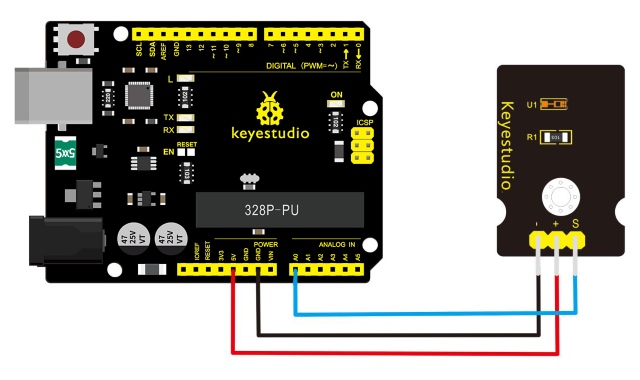

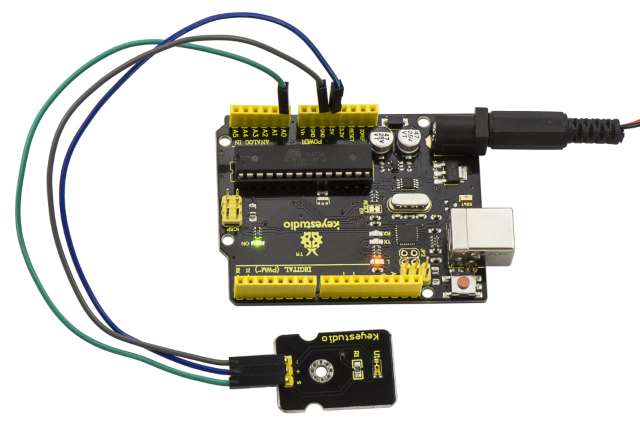

Connection Diagram

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

void setup()

{

Serial.begin(9600); //Set serial baud rate to 9600 bps

}

void loop()

{

int val;

val=analogRead(0);//Read rotation sensor value from analog 0

Serial.println(val,DEC);//Print the value to serial port

delay(100);

}

////////////////////////////////////////////////////////////////////

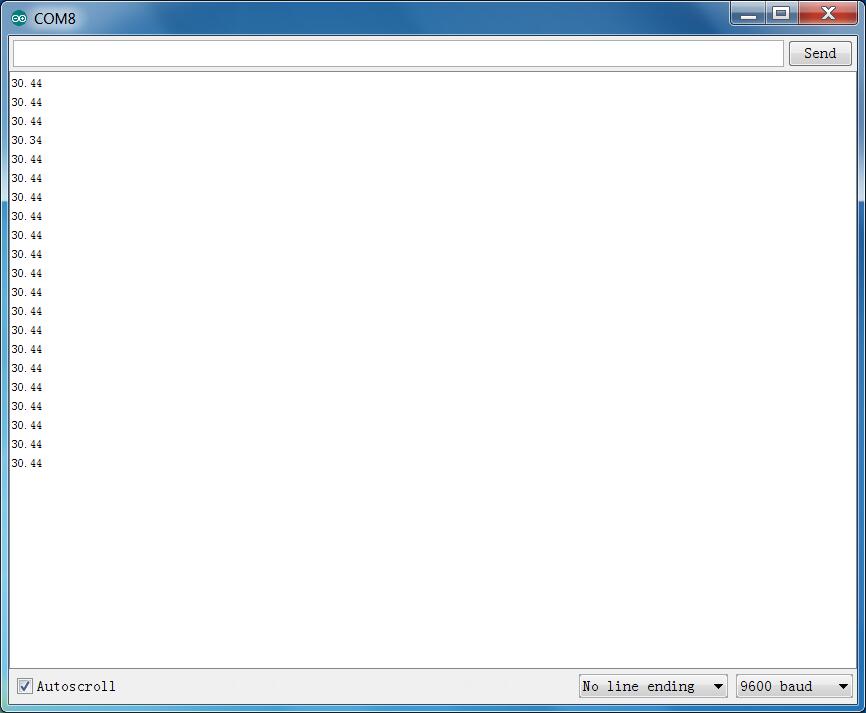

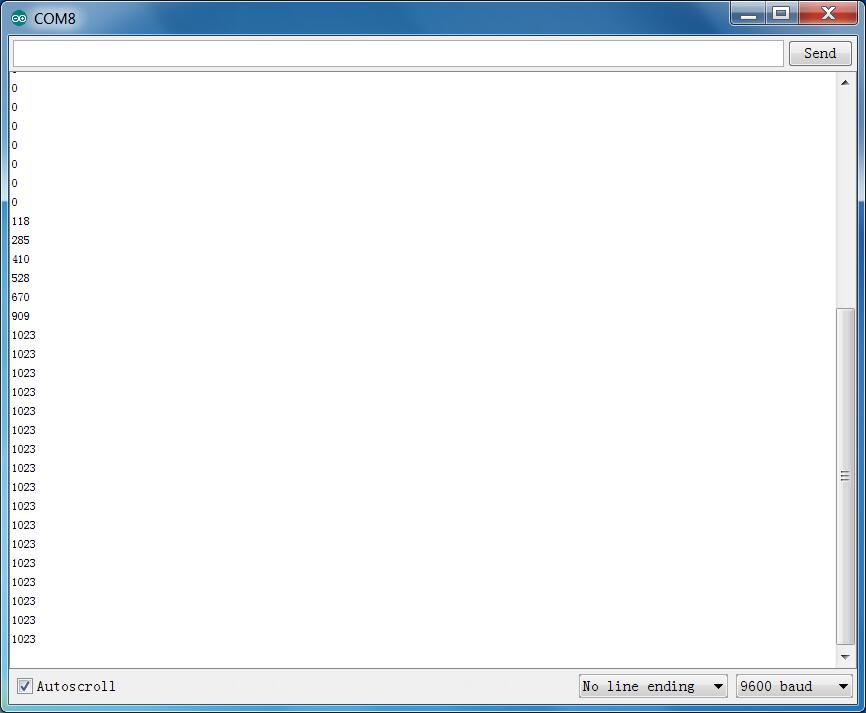

Example Result

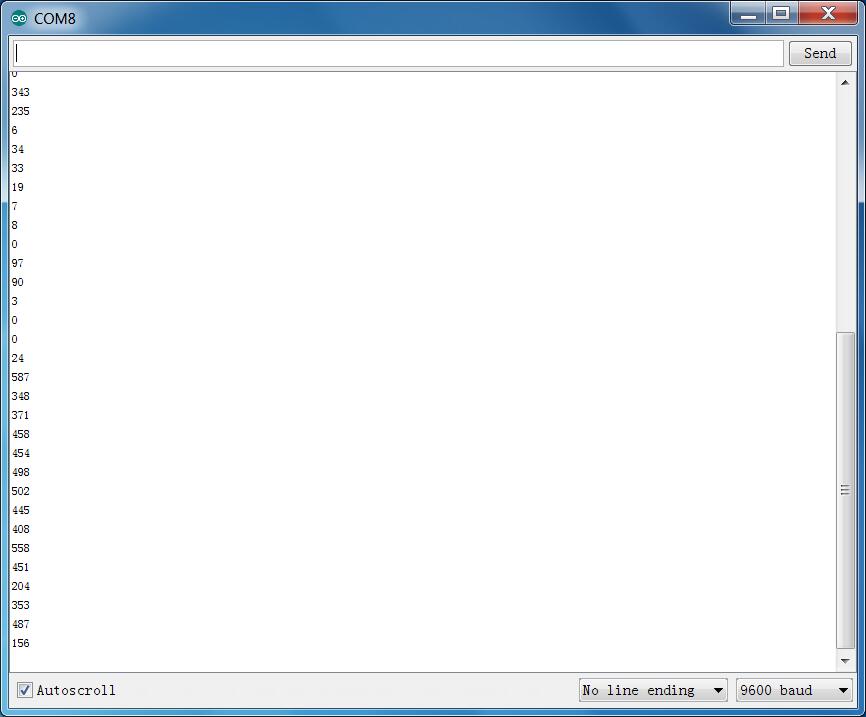

Done wiring and powered up, upload well the code, then open the serial monitor and set the baud rate as 9600, finally you will see the analog value. If rotate the knob on the rotation sensor, the value will be changed within 0-1023. Shown below.

Project 21: Photocell

Description

Photocell is commonly seen in our daily life and is mainly used in intelligent switch, also in common electronic design. To make it easier and more effective, we supply the corresponding modules.

Photocell is a semiconductor. It has features of high sensitivity, quick response, spectral characteristic and R-value consistence, maintaining high stability and reliability in environment extremely such as high temperature and high humidity.

It’s widely used in automatic control switch fields like cameras, garden solar lights, lawn lamps, money detectors, quartz clocks, music cups, gift boxes, mini night lights, sound and light control switches, etc.

Specification

Interface type: analog

Working voltage: 5V

Size: 30*20mm

Weight: 3g

Connection Diagram

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

void setup()

{

Serial.begin(9600); //Set serial baud rate to 9600 bps

}

void loop()

{

int val;

val=analogRead(0);//Read rotation sensor value from analog 0

Serial.println(val,DEC);//Print the value to serial port

delay(100);

}

////////////////////////////////////////////////////////////////////

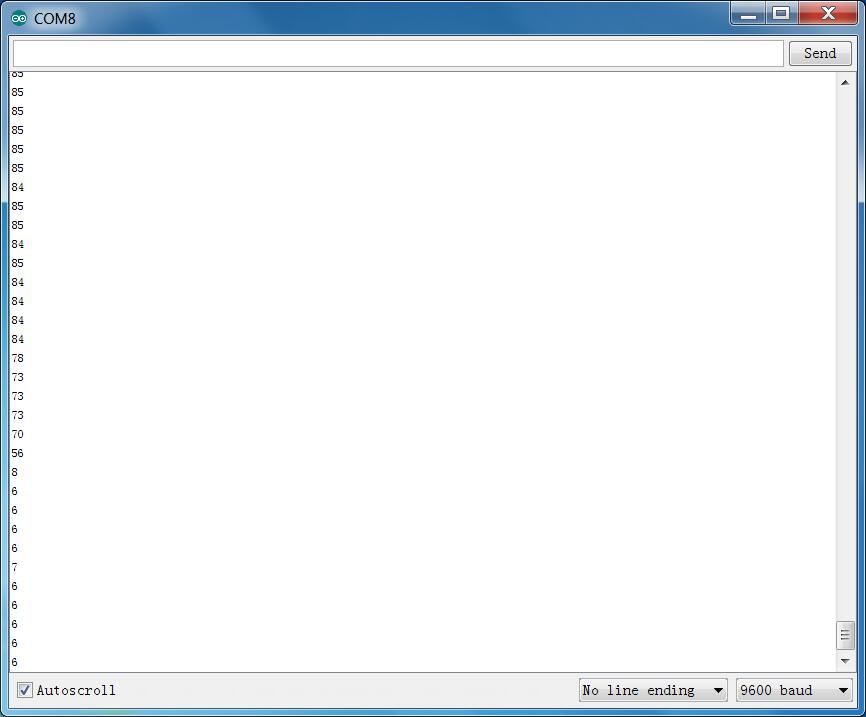

Example Result

Done wiring and powered up, upload well the code, then open the serial monitor, if cover the photocell on the sensor with your hand, you will see the analog value decrease.

Project 22: Analog Sound

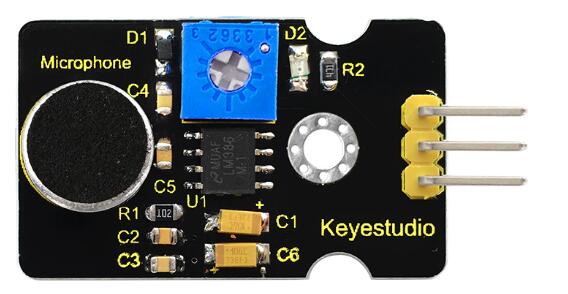

Description

Analog sound sensor is typically used in detecting the volume of ambient sounds. The sensor comes with a potentiometer, so that you can turn it to adjust the signal gain.

You can use it to make some interesting and interactive works, such as a voice operated switch.

Specification

Supply Voltage: 3.3V to 5V

Interface: Analog

Size: 30*20mm

Weight: 4g

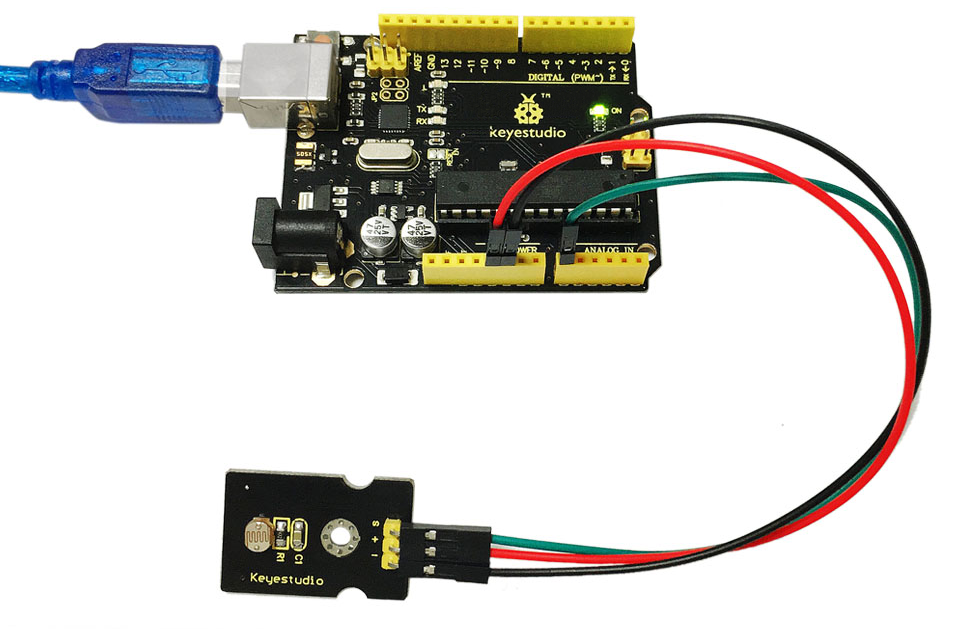

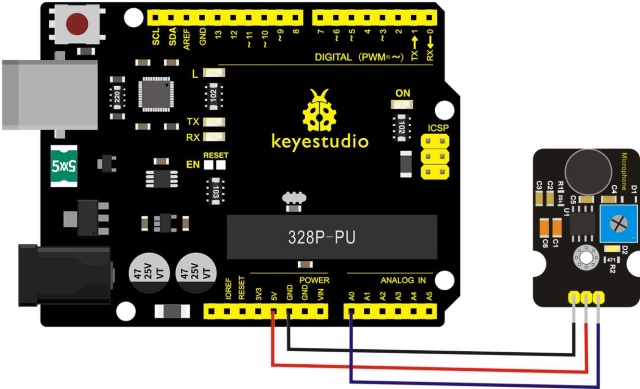

Connection Diagram

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

int sensorPin =A0 ;

int value = 0;

void setup()

{

Serial.begin(9600); }

void loop()

{

value = analogRead(sensorPin);

Serial.println(value, DEC);

delay(50);

}

////////////////////////////////////////////////////////////////////

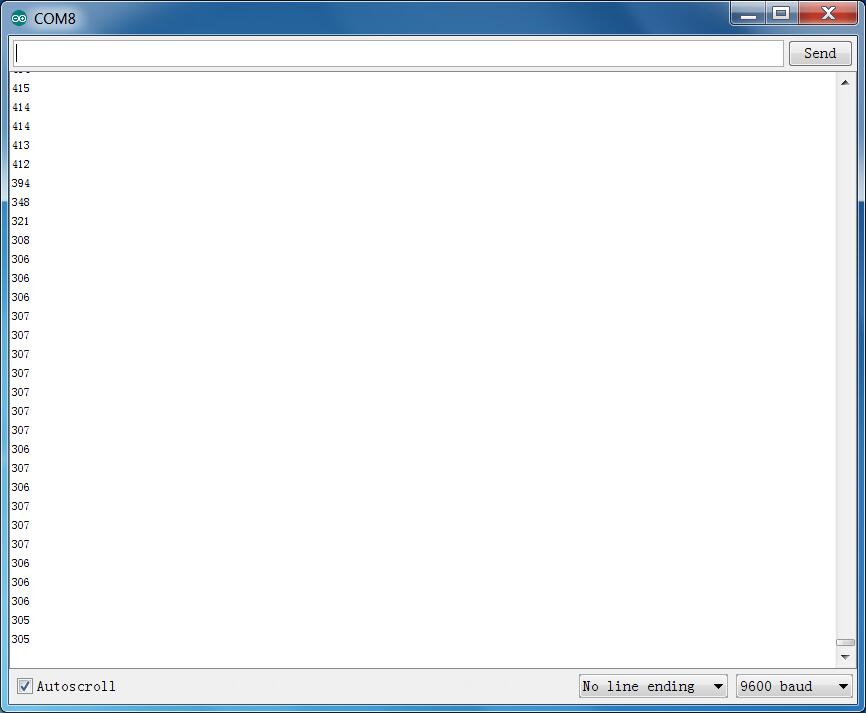

Example Result

Done wiring and powered up, upload well the code, then open the serial monitor and set the baud rate as 9600, you will see the analog value. When talking toward the micro head, the value will increase. Shown below.

Project 23: Water Level

Description

Keyestudio water sensor is easy- to-use, portable and cost-effective, designed to identify and detect water level and water drop.

This small sensor can measure the volume of water drop or water quantity through an array of traces of exposed parallel wires.

Features

smooth conversion between water quantity and analog quantity;

strong flexibility, outputting basic analog value;

low power consumption and high sensitivity;

directly connect to microprocessor or other logic circuits, suitable for a variety of development boards and controllers such as Arduino controller, STC single-chip microcomputer, AVR single-chip microcomputer and more.

Specifications

Operating voltage: DC5V

Operating current: ﹤20mA

Sensor type: Analog

Detection area: 40mm x16mm

Production process: FR4 double-side tinned

Shape design: Anti-skid semi-lunar recess

Working Temperature: 10℃-30℃

Working Humidity: 10%-90% without condensation

Weight: 3g

Dimensions: 65mm x 20mm x 8mm

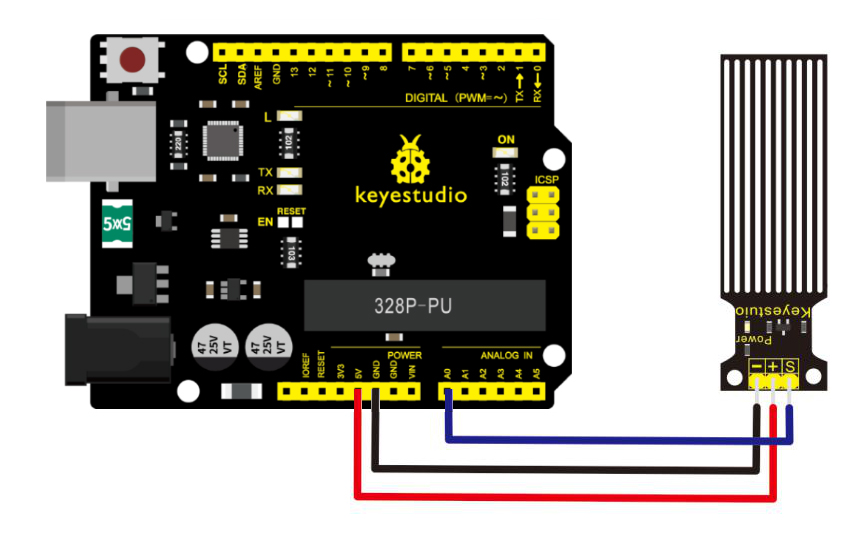

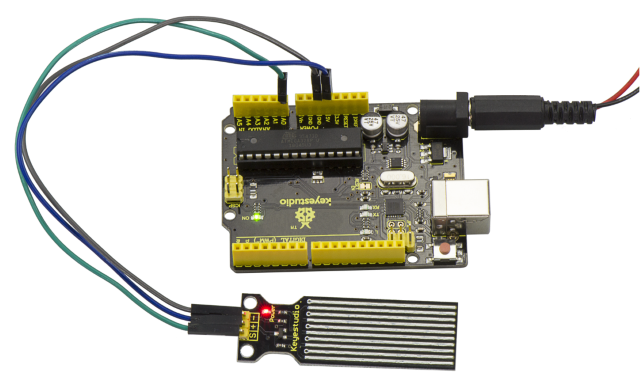

Connection Diagram

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

int analogPin = 0; //connect water sensor to analog interface 0

int led = 13; //LED to digital interface 13

int val = 0; //define the initial value of variable ‘val’ as 0

int data = 0; //define the initial value of variable ‘data’ as 0

void setup()

{

pinMode(led, OUTPUT); //define led as output pin

Serial.begin(9600); //set baud rate at 9600

}

void loop()

{

val = analogRead(analogPin); //read and assign analog value to variable ’val’

if(val>700){ //decide whether variable ‘val’ is over 700

digitalWrite(led,HIGH); //turn on LED when variable ‘val’ is over 700

}

else{

digitalWrite(led,LOW); //turn off LED when variable ‘val’ is under 700

}

data = val; //variable ’val’ assigns value to variable ‘data’

Serial.println(data); //print variable ‘data’ by Serial.print

delay(100);

}

////////////////////////////////////////////////////////////////////

Example Result

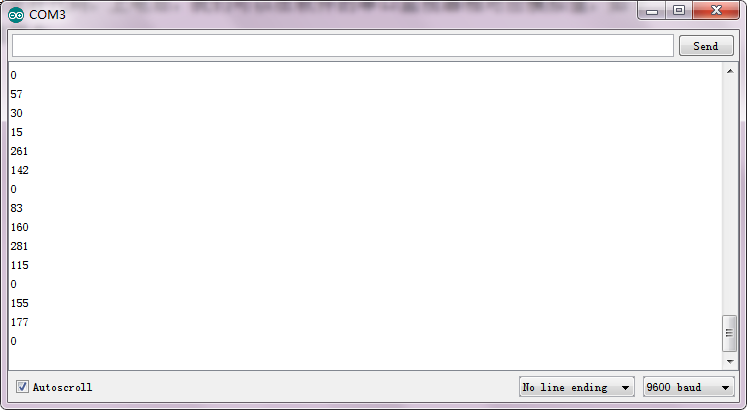

After the above steps are done, let’s do a test on lower water level and check what happens?

Upload well the code to V4.0 board, then open the serial monitor and set the baud rate as 9600.

When place the sensor into the water at different level, you will see the value change correspondingly.

Furthermore, you can set an alarm value and connect a buzzer to make an alarm.

The LED can’t light up when water level haven’t reach alarm value. If water level reaches the alarm value, LED will be turned on and buzzer will sound to make an alarm.

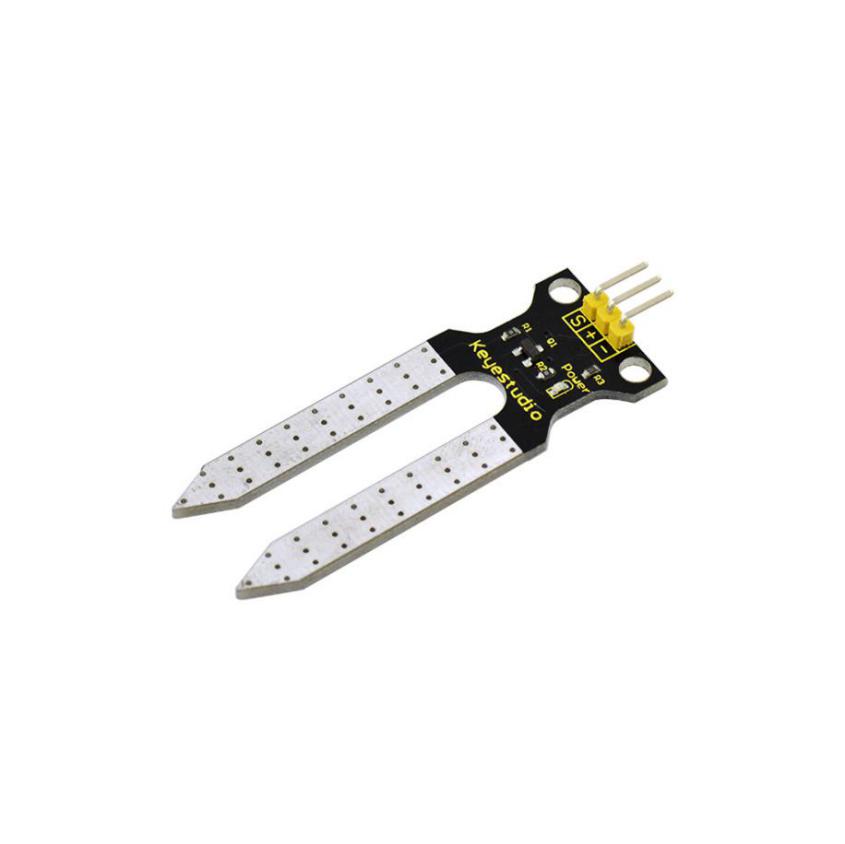

Project 24: Soil Moisture

Description

This is a simple soil humidity sensor aimed to detect the soil humidity. If the soil is in lack of water, the analog value output by the sensor will decrease, otherwise, it will increase.

If you use this sensor to make an automatic watering device, it can detect whether your botany is thirsty to prevent it from withering when you go out.

Combine this sensor with Arduino controller can make your plant more comfortable and your garden more smarter.

The soil humidity sensor module is not as complicated as you might think, so if you need to detect the soil in your project, it will be your best choice.

The sensor is set with two probes which are inserted into the soil. If the current goes through the soil, the sensor will get resistance value by reading the current changes between the two probes, then convert the resistance value into moisture content.

The higher moisture (less resistance), the higher conductivity the soil has.

The surface of the sensor has undergone metallization process to prolong its service life. Insert it into the soil and then use the AD converter to read it. With the help of this sensor, the plant can remind of you: I need water.

Specification

Power Supply Voltage: 3.3V or 5V

Working Current: ≤ 20mA

Output Voltage: 0-2.3V (When the sensor is totally immersed in water, the voltage will be 2.3V) The higher humidity, the higher the output voltage.

Sensor type: Analog output

Interface: Pin1- signal, Pin2- GND, Pin3 - VCC

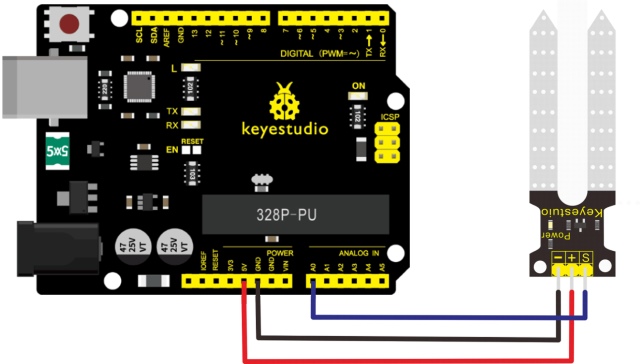

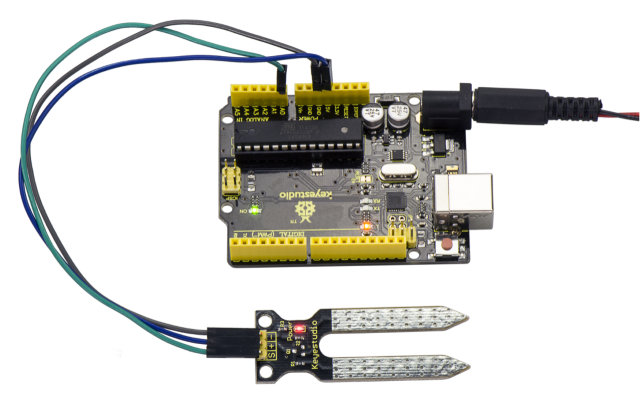

Connection Diagram

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

/*

# Example code for the moisture sensor

# Connect the sensor to the A0(Analog 0) pin on the Arduino board

# the sensor value description

# 0 ~300 dry soil

# 300~700 humid soil

# 700~950 in water

*/

void setup(){

Serial.begin(57600);

}

void loop(){

Serial.print("Moisture Sensor Value:");

Serial.println(analogRead(0));

delay(100);

}

////////////////////////////////////////////////////////////////////

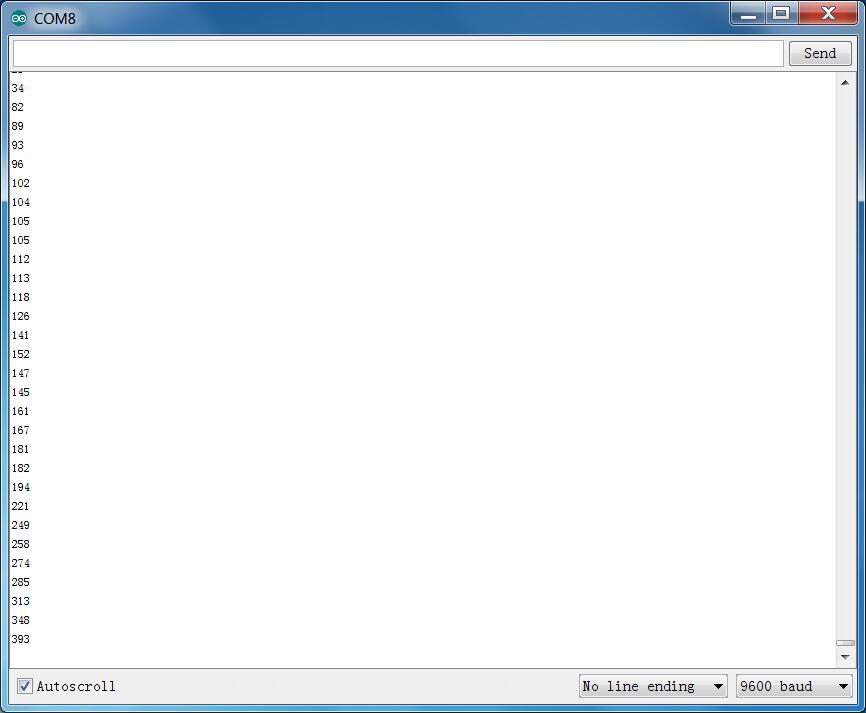

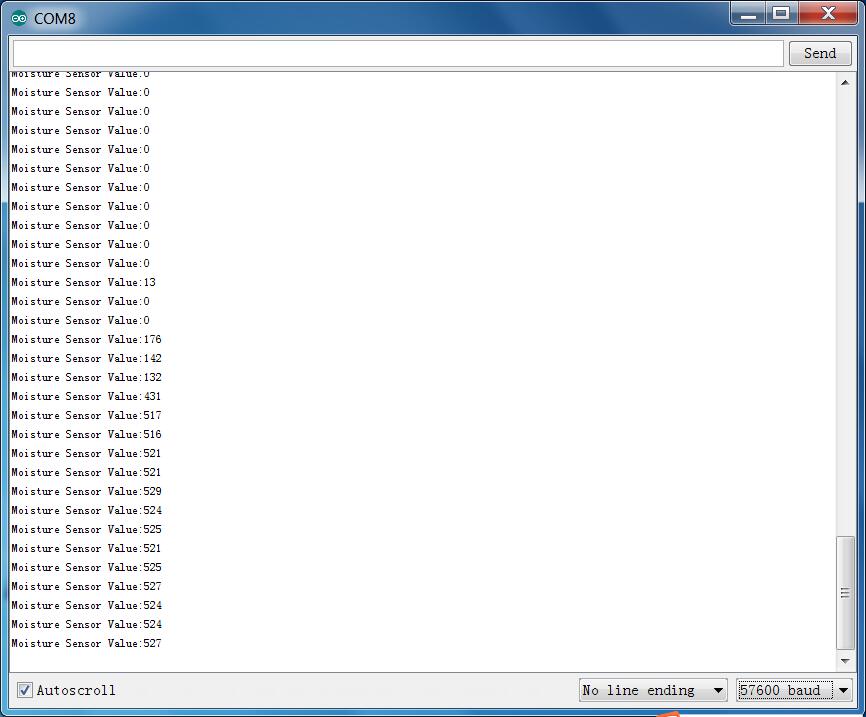

Example Result

Done wiring and powered up, upload well the code, then open the serial monitor and set the baud rate as 57600, you will see the value. When the sensor detects the moisture, the value will make corresponding changes. Shown below.

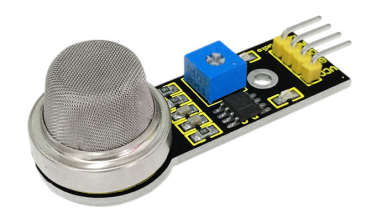

Project 25: Analog Gas

Description

This analog gas sensor MQ2 is used in gas leakage detecting equipment in both consumer electronics and industrial markets. This sensor is suitable for detecting LPG, I-butane, propane, methane, alcohol, Hydrogen and smoke.

The detecting scope of this sensor is very wide and it has high sensitivity and quick response.

In addition, the sensitivity can be adjusted by rotating the potentiometer on the sensor.

Specification

Power supply: 5V

Interface type: Analog

Simple drive circuit

Stable and long lifespan

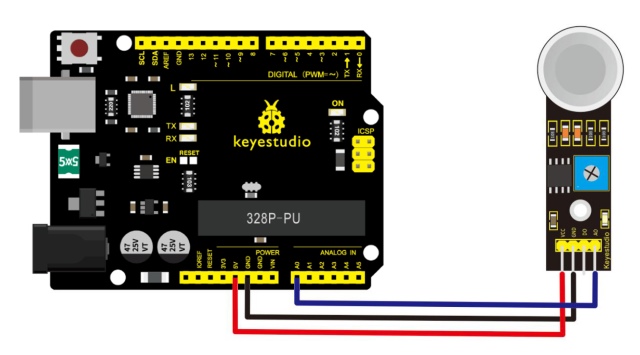

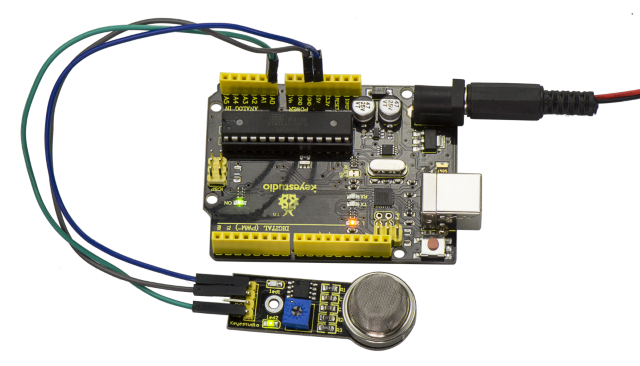

Connection Diagram

Connect the A0 pin of module to Analog A0 of V4.0 board, connect the GND pin to GND port, VCC pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

//Arduino Sample Code

void setup()

{

Serial.begin(9600); //Set serial baud rate to 9600 bps

}

void loop()

{

int val;

val=analogRead(0);//Read Gas value from analog 0

Serial.println(val,DEC);//Print the value to serial port

delay(100);

}

////////////////////////////////////////////////////////////////////

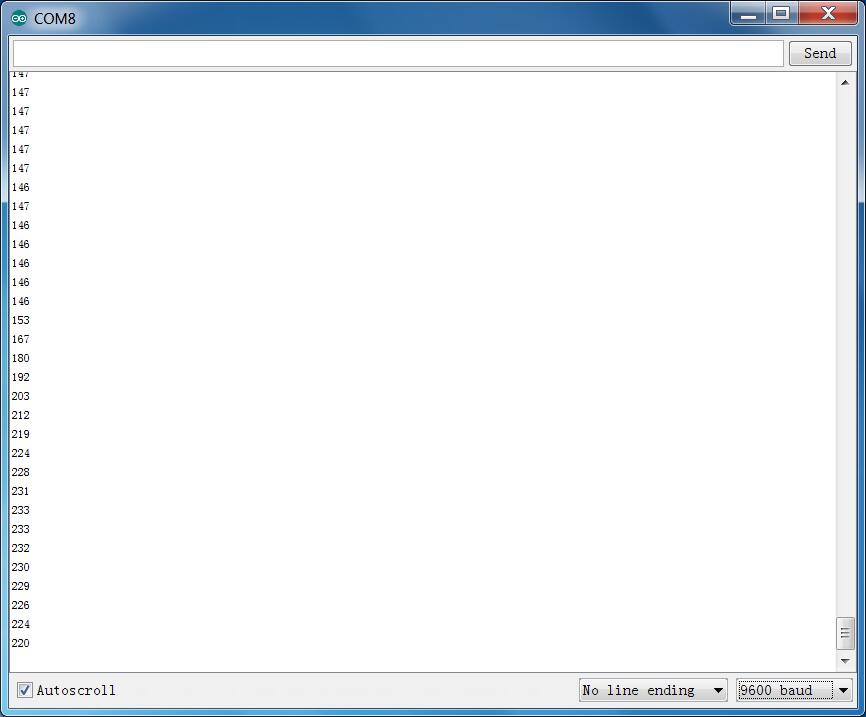

Example Result

Done wiring and powered up, upload well the code, then open the serial monitor and set the baud rate as 9600, you will see the analog value. When detecting the gas, the value will make a change.

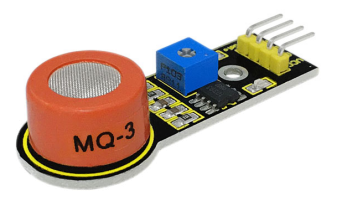

Project 26: Analog Alcohol

Description

This analog sensor-MQ3 is suitable for detecting the alcohol. It can be used in a breath [analyzer](file:///C:\Documents%2520and%2520Settings\Administrator\桌面\javascript:void(0);).

It has good selectivity because it has higher sensitivity to alcohol and lower sensitivity to Benzine.

The sensitivity can be adjusted by rotating the potentiometer on the sensor.

Specification

Power supply: 5V

Interface type: Analog

Simple drive circuit

Stable and long service life

Quick response and High sensitivity

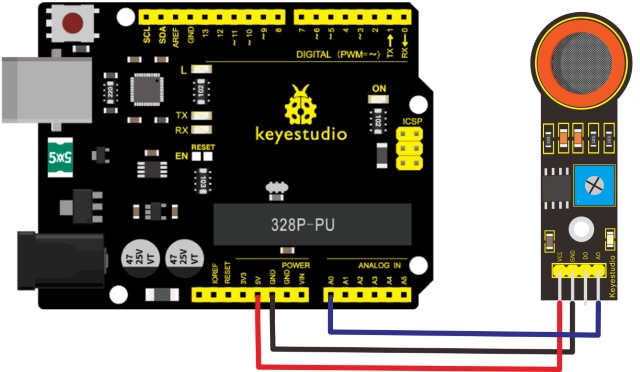

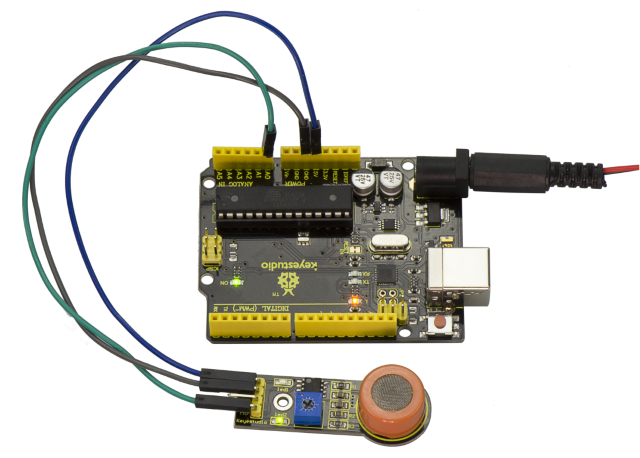

Connection Diagram

Connect the A0 pin of module to Analog A0 of V4.0 board, connect the GND pin to GND port, VCC pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

//Arduino Sample Code

void setup()

{

Serial.begin(9600); //Set serial baud rate to 9600 bps

}

void loop()

{

int val;

val=analogRead(0);//Read Gas value from analog 0

Serial.println(val,DEC);//Print the value to serial port

delay(100);

}

////////////////////////////////////////////////////////////////////

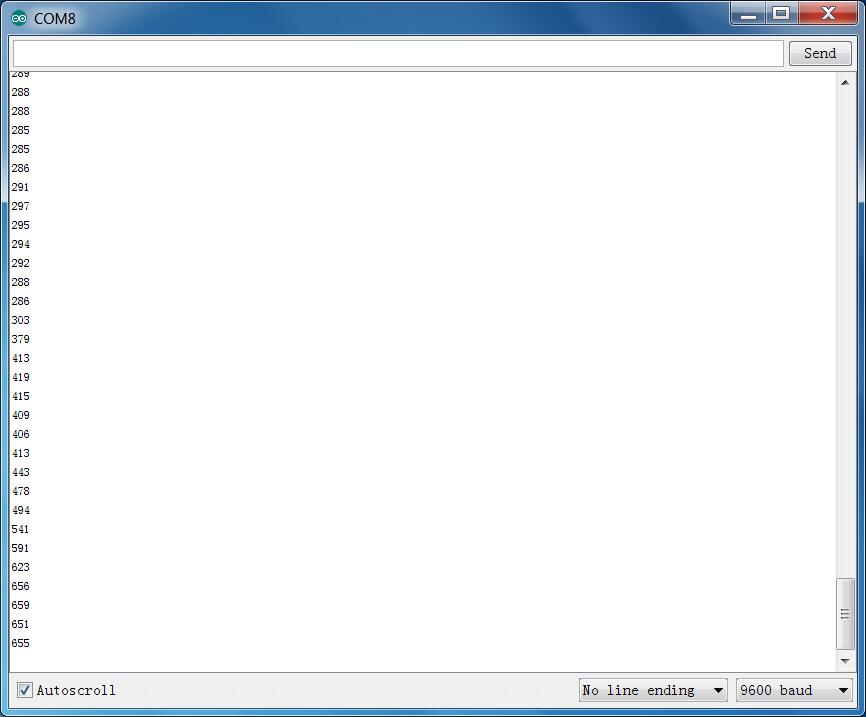

Example Result

Done wiring and powered up, upload well the code, then open the serial monitor and set the baud rate as 9600, you will see the analog value. When detecting the alcohol gas, the value will make a change.

Project 27: Steam Sensor

Description

Steam sensor is an analog sensor and can be made as a simple rainwater detector and liquid level switch. When humidity on the face of this sensor rises, output voltage will increase.

Caution: connection parts is non-waterproof, so please don’t put them into water.

Parameters

Working Voltage: 3.3V or 5V

Working Current: <20mA

Range of Working Temperature: -10℃~+70℃

Interface Type: Analog Signal Output

Pin Definition

S pin: for Signal Output

Positive pin (+): for Power Supply (VCC)

Negative pin (-): for Ground (GND)

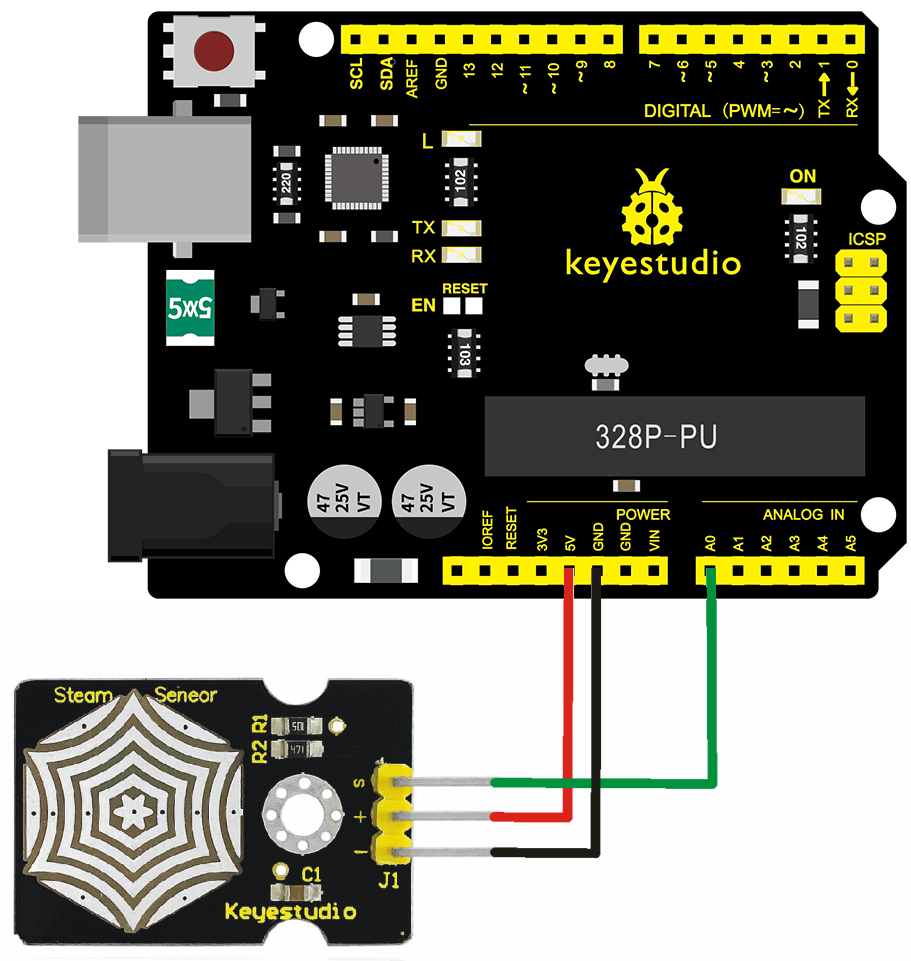

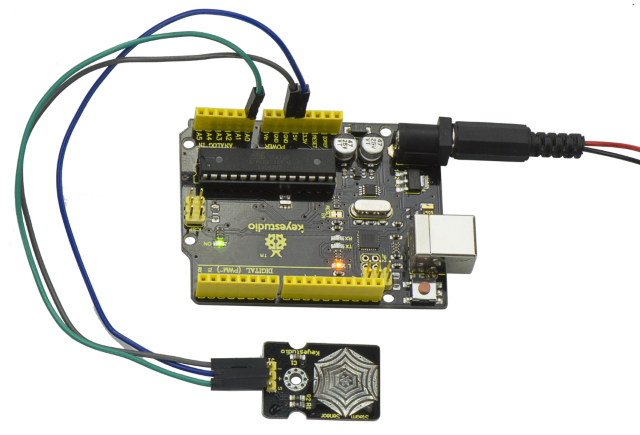

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 board*1

Steam sensor*1

USB Cable*1

Jumper wire*3

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

////////////////////////////////////////////////////////////////////

void setup()

{

Serial.begin(9600); //open serial port, and set baud rate at 9600bps

}

void loop()

{

int val;

val=analogRead(0); //plug vapor sensor into analog port 0

Serial.print("Moisture is ");

Serial.println(val,DEC); //read analog value through serial port printed

delay(100);

}

////////////////////////////////////////////////////////////////////

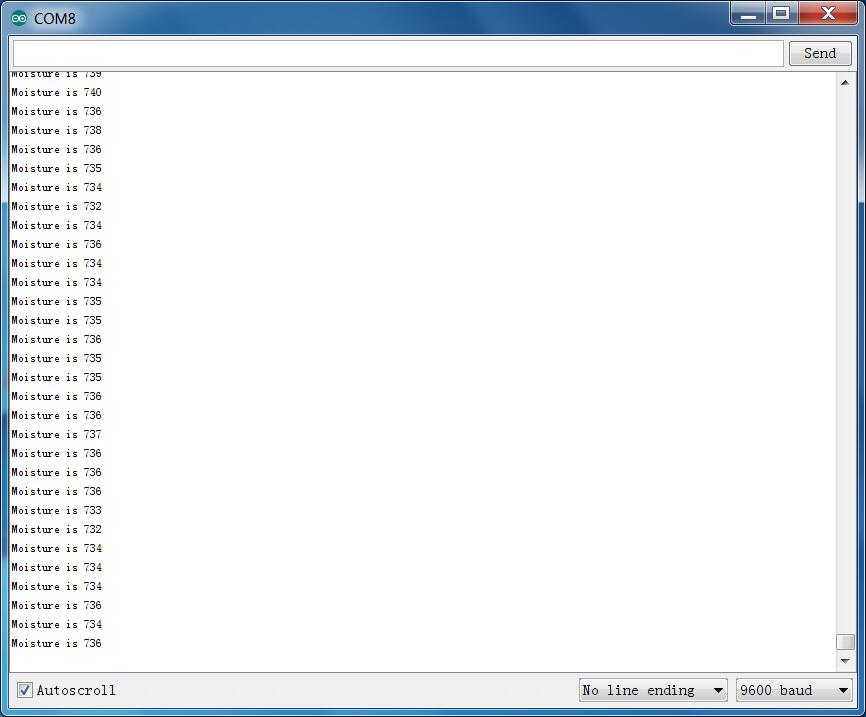

Example Result

When detecting different degrees of humidity, the sensor will get the feedback of different current value. Shown as the following picture.

Due to the limited condition, you can put a drop of water on the sensor, the moisture value will be changed on serial monitor of Arduino software.

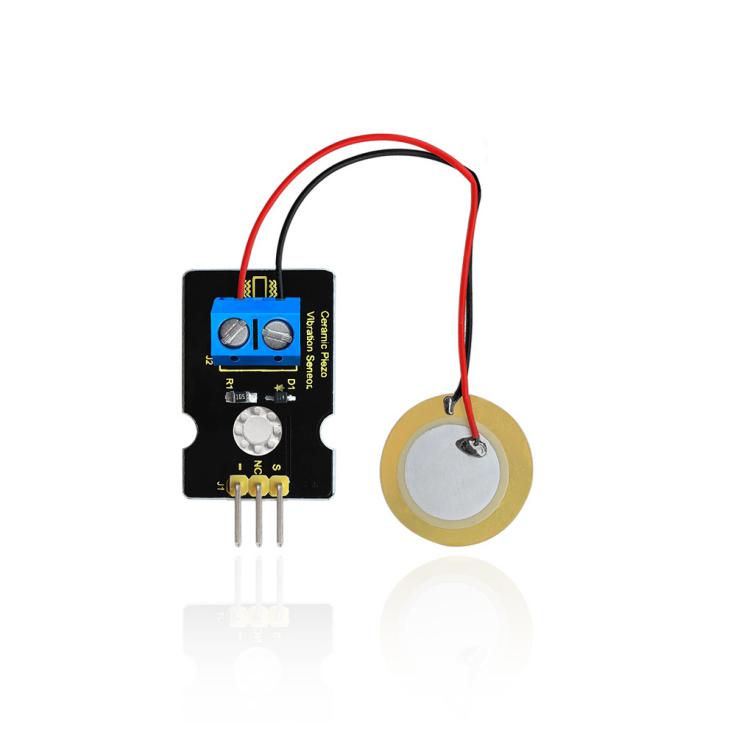

Project 28: Analog Ceramic Vibration

Description

This vibration sensor is based on piezoelectric ceramic chip analog vibration. It makes use of the anti-conversion process that piezoelectric ceramic vibration will generate the electric signals. When vibrating the piezoelectric ceramic chip, the sensor’s signal terminal will generate electrical signals.

The sensor can be used with Arduino dedicated sensor shield, and Arduino analog port can perceive weak vibration signals, so that it can make interactive works related to vibration, such as electronic drum.

Connect the vibration sensor to the analog port A0 of Arduino UNO. When vibrating the sensor in different degrees, you will see the different output value displayed on serial monitor of Arduino software.

Specification

Supply Voltage: 3.3V to 5V

Working Current:<1mA

Working Temperature Range:-10℃~+70℃

Output Signal:analog signal

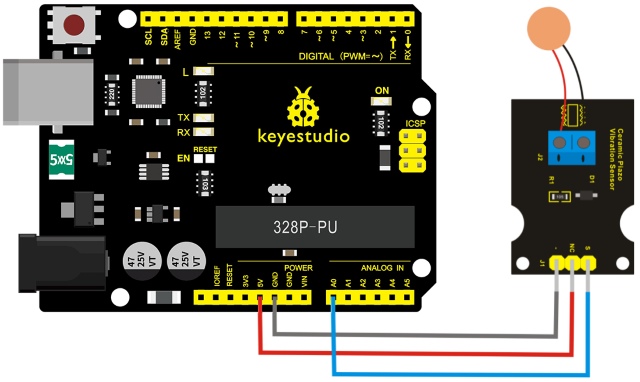

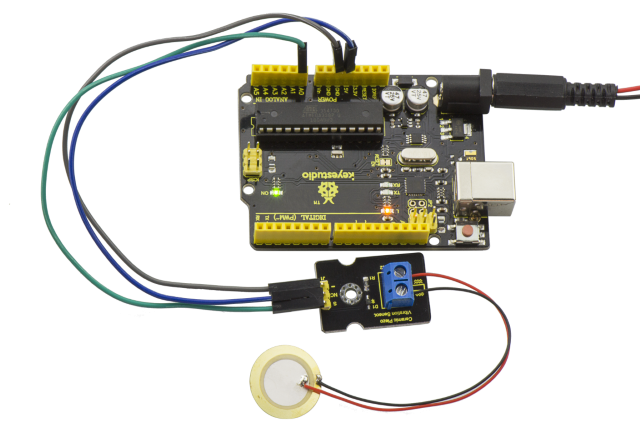

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 board*1

vibration sensor*1

USB Cable*1

Jumper wire*3

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, NC pin to 5V port.

Sample Code

Copy and paste the below code to Arduino software.

///////////////////////////////////////////////////////////

void setup()

{

Serial.begin(9600); //Open the serial to set the baud rate as 9600bps

}

void loop()

{

int val;

val=analogRead(0); //Connect the sensor to analog interface A0

Serial.print("Vibration is ");

Serial.println(val,DEC);//Print the analog value read on serial port

delay(100);

}

///////////////////////////////////////////////////////////

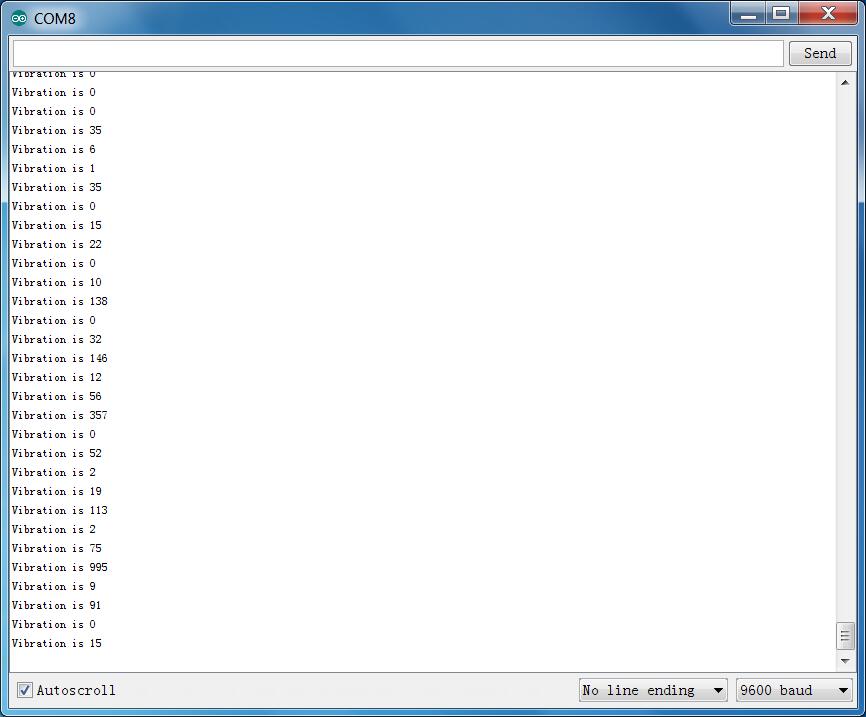

Example Result

Wiring as the above diagram and upload well the code, then open the serial monitor and set the baud rate as 9600.

When vibrating the ceramic chip, you will see the data change as the figure shown below.

Project 29: Voltage Detection

Description

Since the electronic products are various, the voltage of the power supply is also different. It is indeed necessary to detect it with a suitable voltage detection module or controller.

The maximum input voltage of the controller’s analog interface is 5V, which means that the voltage greater than 5V will not be detected.

However, this voltage detection module can achieve to detect the voltage greater than 5 V.

It is designed on the basis of resistive voltage divider principle, which can make the input voltage of bindingpost interface narrow 5 times, and the analog input voltage is up to 5 V, thus the input voltage of voltage detection module is not greater than 5V * 5 = 25 V (if using 3.3 V system, the input voltage is not greater than 3.3 V *5 = 16.5 V).

The AVR chip is 10-bit AD, so the analog resolution of this module is 0.00489 V (5V / 1023), and the minimum input voltage is 0.00489V * 5 = 0.02445 V.

When connect this sensor to expansion board using 3Pin wire, it can not only easily detect the magnitude of the voltage power and monitor the electric quantity of battery for interactive media works or robot, but also can combine with IIC LCD1602 LCD module to display the voltage or make a voltage monitor.

Specification

Working voltage: 0V-25V DC

Signal type: analog signal

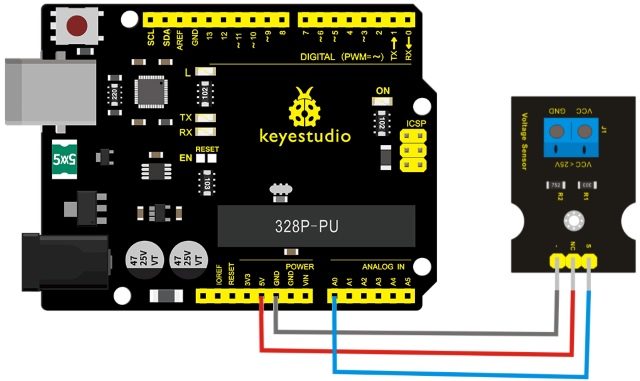

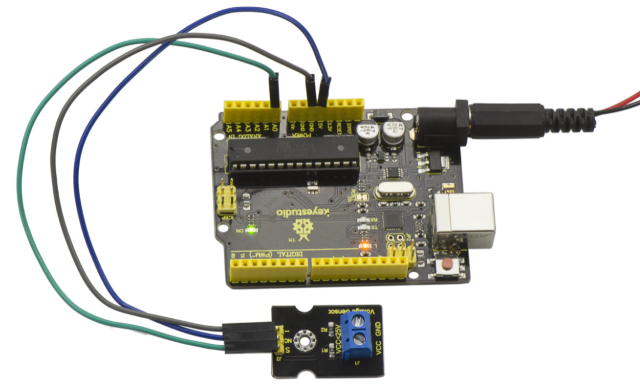

Connection Diagram

First, you need to prepare the following parts before connection:

V4.0 board*1

Voltage sensor*1

USB Cable*1

Jumper wire*3

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, NC pin to 5V port.

Sample Code

////////////////////////////////////////////////////////////////////

int analogpin=0; // Define analogpin as analog port 0

int val,val5; //Define variables val,val5

int val2=0; //Define variables val2

int val3=0; //Define variables val3

int val4=0; //Define variables val4

void setup()

{

Serial.begin(9600); //Set baud rate of 9600

}

void loop()

{

int val,val5;

float val1;

val=analogRead(analogpin); //Read the value of the analog port and assign it to the variable val

val1=val/3.9;

val5=(int)val1;

val3=val5/100;

val2=(val5%100)/10;

val4=val5%10;

Serial.print("$CLEAR\r\n"); //clear the screen

Serial.print("$GO 1 1\r\n");

Serial.print("$PRINT Voltage:\r\n");

Serial.print("$GO 1 9\r\n");

Serial.print("$PRINT ");

Serial.print(val3); //The serial port prints the value of the variable val3

Serial.print(val2); //The serial port prints the value of the variable val2

Serial.print("."); //The serial port prints out a point"."

Serial.print(val4); //The serial port prints the value of the variable val4

Serial.println("V"); //The serial port prints out capital “ V”

delay(100); //delay 0.1 second

}

////////////////////////////////////////////////////////////////////

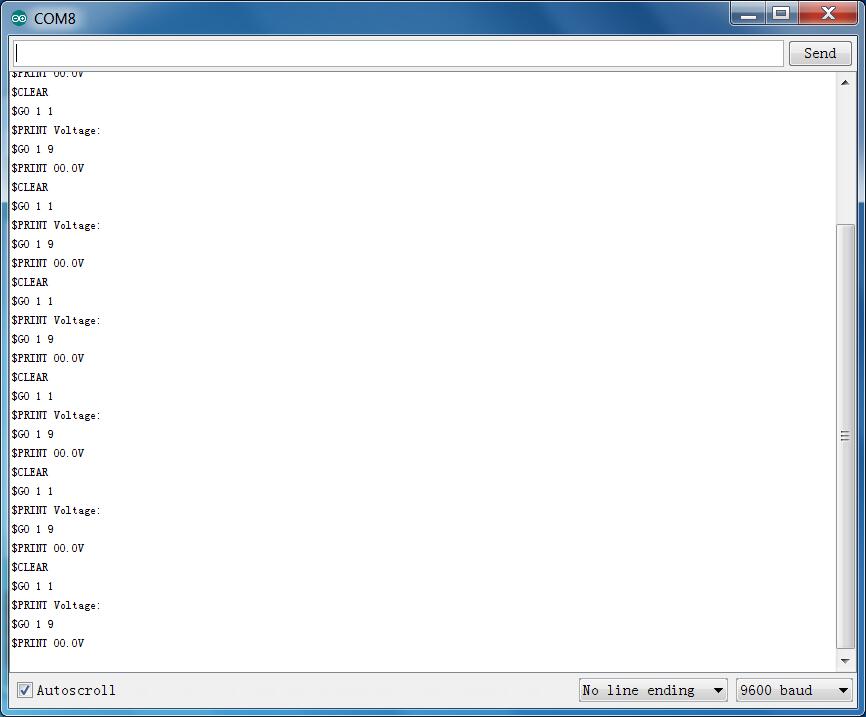

Example Result

Done as the above wiring, compile and upload the code, powered-on, then open the serial port monitor, it will print out the detected voltage value shown below.

Project 30: Pressure Detection

Description

This sensor adopts the new flexible nano pressure sensitive material with ultra thin film pad. It has the functions of water-proof and pressure detection.

When the sensor detects the outside pressure, the resistance of sensor will make a change.

So using the circuit, it can convert the pressure signal that senses pressure change into the corresponding electric signal output.

In this way, we can get the conditions of pressure changes by detecting the signal changes.

Parameters

Working Voltage:DC 3.3V—5V

Range:0-10KG

Thickness:<0.25mm

Response Point:<20g

Repeatability:<±5.8%(50% load)

Accuracy:±2.5%(85% range interval)

Durability:>100 thousand times

Initial Resistance:>100MΩ(no load)

Response Time:<1ms

Recovery Time:<15ms

Working Temperature:﹣20℃—60℃

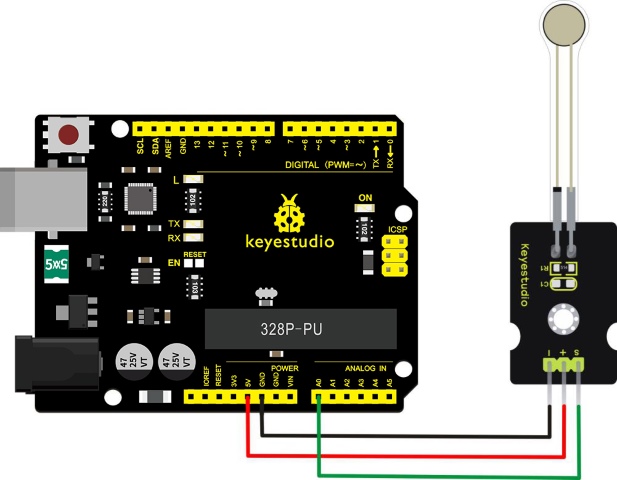

Connection Diagram

Firstly you need to prepare the following parts before connection.

V4.0 Board*1

Pressure sensor*1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the code below to Arduino software.

///////////////////////////////////////////////////////////////

int s_pin = A0;

void setup()

{

Serial.begin(9600);

pinMode(s_pin,INPUT);

}

void loop()

{

Serial.println(analogRead(s_pin));

delay(500);

}

///////////////////////////////////////////////////////////////

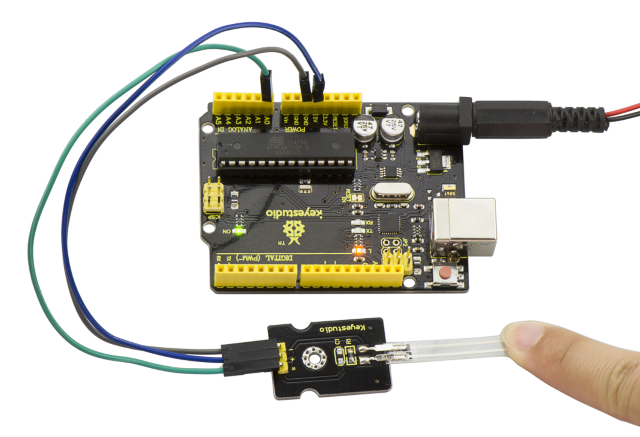

Example Result

Wiring well and uploading the code, open the serial monitor on Arduino software.

Then, press the sensor with your hand tightly, the value shown on the monitor is increasing.

Project 31: Ambient Light

Description

At some point you are going to sense ambient brightness with better precision than your trusty photoresistor without adding complexity to your project. When that day comes, go get yourself a TEMT6000 ambient light sensor.

The TEMT6000 is supposed to be adapted to the sensitivity of the human eye, but found it preformed sub-par in low light conditions. It does however work very well reacting to very small changes in a large range of brightness. Because it is meant to mimic the human eye, it does not react well to IR or UV light, so just make sure to note that when using it in your project.

Specification

Supply Voltage: +5VDC 50mA

Size: 36.5*16mm

Weight: 4g

Connection Diagram

Firstly you need to prepare the following parts before connection.

V4.0 Board*1

TEMT6000 ambient light sensor*1

USB Cable*1

Jumper Wire*3

This is an incredibly simple part, just connect power and ground, and the signal pin to analog input port, if done connecting, the sensor will output analog voltage, that ramps up when it gets brighter. You can power it with 3.3V as you like, the output value will just be much lower.

Sample Code

You can not get more simpler than this – This just reports the reading value from the sensor to the serial terminal: 0-1023 with 1023 being very bright, and 0 being very dark.

///////////////////////////////////////////////////////////////

int temt6000Pin = 0;

void setup() {

Serial.begin(9600);

}

void loop() {

int value = analogRead(temt6000Pin);

Serial.println(value);

delay(100); //only here to slow down the output so it is easier to read

}

///////////////////////////////////////////////////////////////

Example Result

Wiring well and uploading the code above, open the serial monitor of Arduino software.

Then cover the sensor with your hand or a paper, the light becomes weak, finally you will see the value showed on monitor decreasing.

Project 32: Ultraviolet Light

Description

Keyestudio GUVA-S12SD ultraviolet sensor is used to detect ultraviolet light. It includes GUVA-S12SD applied to measure ultraviolet index of intelligent wearable device, such as watches, smart phone and outdoor device with UV index detecting.

It can be also used to monitor the intensity of ultraviolet light or used as a UV flame detector when disinfecting things by ultraviolet light.

Parameters

Size: 15mm×30mm×0.7mm

Supply Voltage: 2.5V~5V

Output Signal: Analog Signal

Detecting Range of Spectrum: 240-370nm

Active Region: 0.076mm2

Responsivity: 0.14A/W

Dark Current: 1nA

Light Current: 101~125nA UVA Light, 1mW/cm2

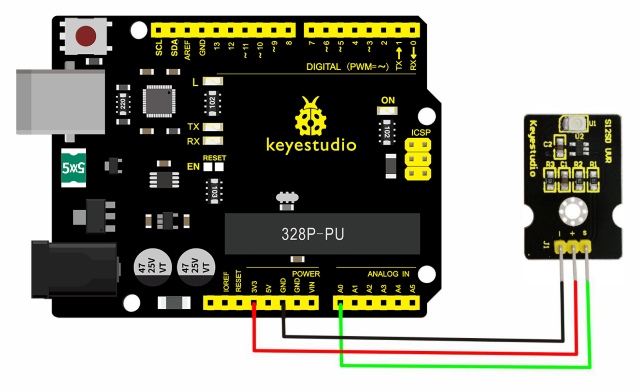

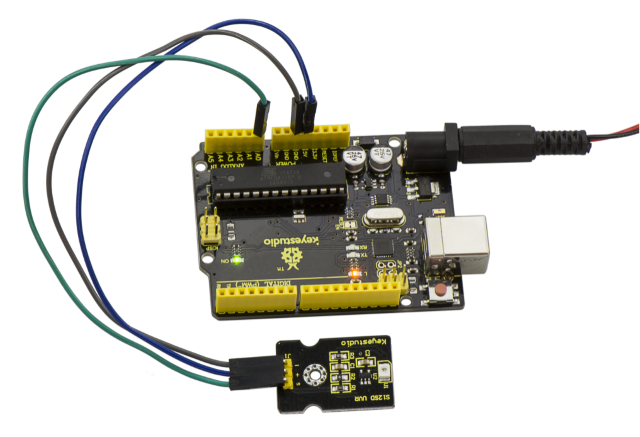

Connection Diagram

Firstly you need to prepare the following parts before connection.

V4.0 Board*1

GUVA-S12SD 3528 Ultraviolet Sensor *1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Analog A0 of V4.0 board, connect the negative pin to GND port, positive pin to 3V3 port.

Sample Code

Copy and paste the code below to Arduino software.

///////////////////////////////////////////////////////////////

/*

AnalogReadSerial

Reads an analog input on pin 0, prints the result to the serial monitor.

Attach the center pin of a potentiometer to pin A0, and the outside pins to +5V and ground.

This example code is in the public domain.

*/

// the setup routine runs once when you press reset:

void setup() {

// initialize serial communication at 9600 bits per second:

Serial.begin(9600);

}

// the loop routine runs over and over again forever:

void loop() {

// read the input on analog pin 0:

int sensorValue = analogRead(A0);

// print out the value you read:

Serial.println(sensorValue);

delay(1); // delay in between reads for stability

}

///////////////////////////////////////////////////////////////

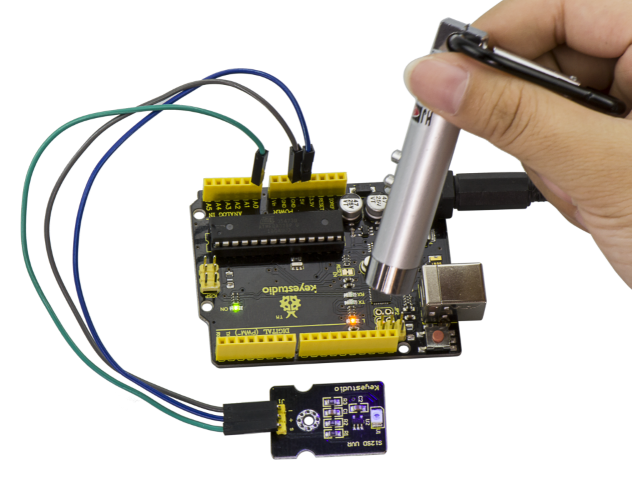

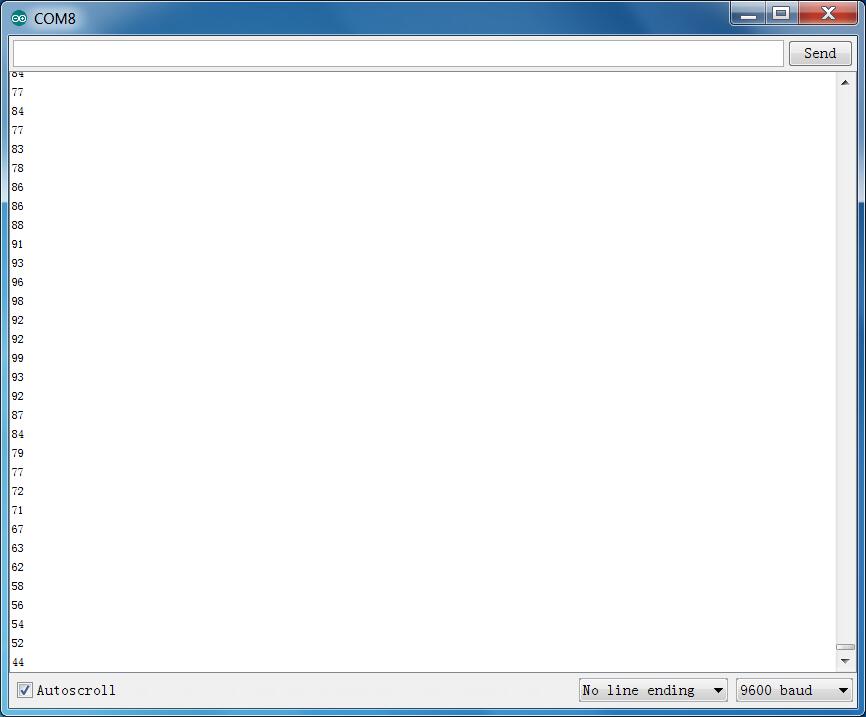

Example Result

Wire it up well and upload the program code, then open serial monitor, it will display the data.

If shine UV light to the sensor, the data on serial monitor is changing shown as the following picture.

Project 33: Digital IR Receiver

Description

IR is widely used in remote control. With this IR receiver, Arduino project is able to receive command from any IR remoter controllers if you have the right decoder. Well, it will be also easy to make your own IR controller using IR transmitter.

Specification

Power Supply: 5V

Interface: Digital

Modulation Frequency: 38Khz

Module Interface Socket: JST PH2.0

Size: 30*20mm

Weight: 4g

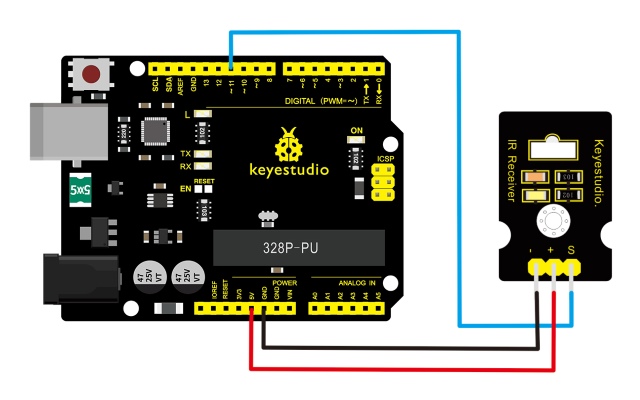

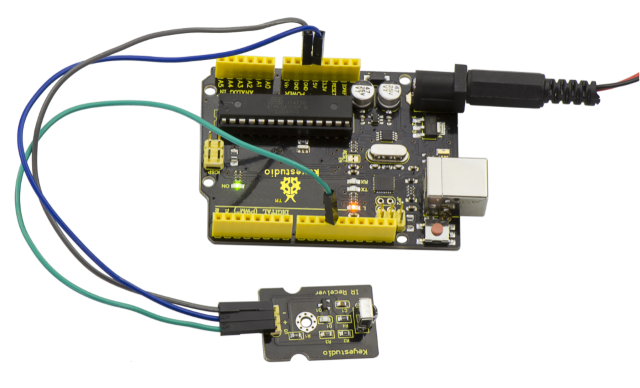

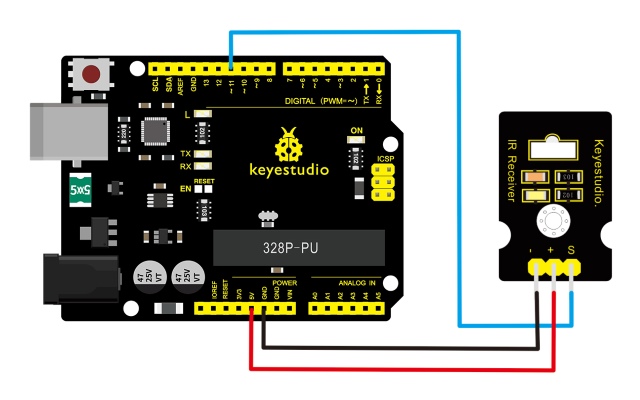

Connection Diagram

Firstly you need to prepare the following parts before connection.

V4.0 Board*1

IR Receiver module*1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 11 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

In the sample code below Digital pin 11 is in use, you may either change your wiring or change the sample code to match.

Sample Code

Copy and paste the code below to Arduino software.

///////////////////////////////////////////////////////////////

#include <IRremote.h>

int RECV_PIN = 11;

IRrecv irrecv(RECV_PIN);

decode_results results;

void setup()

{

Serial.begin(9600);

irrecv.enableIRIn(); // Start the receiver

}

void loop() {

if (irrecv.decode(&results)) {

Serial.println(results.value, HEX);

irrecv.resume(); // Receive the next value

}

}

///////////////////////////////////////////////////////////////

Note: before compiling the code, do remember to place the library into libraries directory of Arduino IDE. Otherwise, compiling will fail.

IR Remote Library Includes some sample codes for sending and receiving.

https://github.com/shirriff/Arduino-IRremote

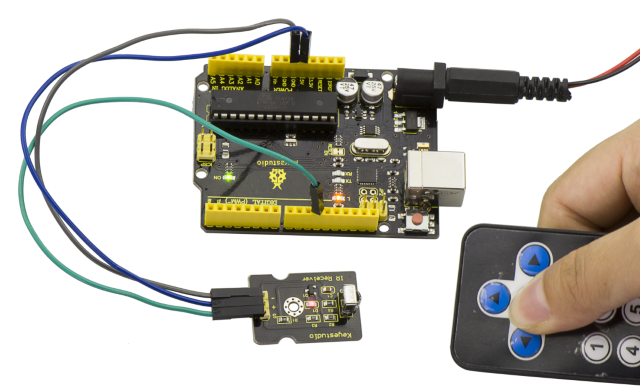

Example Result

Done wiring and uploading the code, then control the IR receiver module by an infrared remote control, D1 led will flash.

Project 34: Digital IR Transmitter

Description

IR transmitter module is designed for IR communication, which is widely used for operating the television device from a short line-of-sight distance.

Since infrared (IR) remote control uses light, it requires line of sight to operate the destination device. The signal can, however, be reflected by mirrors, just like any other light sources.

Infrared receivers also tend to have a more or less limited operating angle, which mainly depends on the optical characteristics of the phototransistor.

However, it’s easy to increase the operating angle using a matte transparent object in front of the receiver.

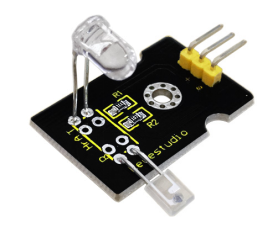

Specification

Power Supply: 3-5V

Infrared center frequency: 850nm-940nm

Infrared emission angle: about 20 degrees

Infrared emission distance: about 1.3m (5V 38Khz)

Interface socket: JST PH2.0

Mounting hole: inner diameter is 3.2mm, spacing is 15mm

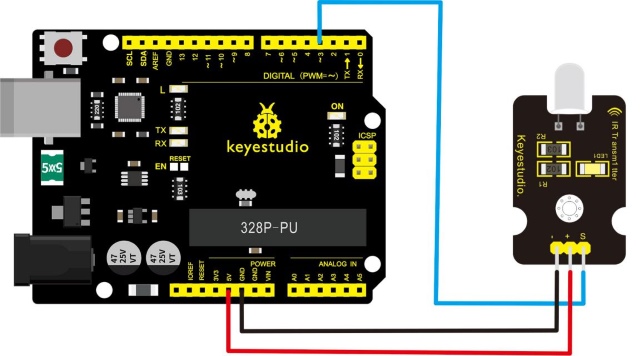

Connection Diagram

Firstly you need to prepare the following parts before connection.

V4.0 Board*1

IR Transmitter module*1

USB Cable*1

Jumper Wire*3

Connect the S pin of module to Digital 3 of V4.0 board, connect the negative pin to GND port, positive pin to 5V port.

Sample Code 1:

int led = 3;

void setup() {

pinMode(led, OUTPUT);

}

void loop() {

digitalWrite(led, HIGH);

delay(1000);

digitalWrite(led, LOW);

delay(1000);

}

In the darkness of the environment, you are going to see blinking blue light on phone’s screen when using camera to shoot the infrared LED.

Upload well the above code to the board, the led on the sensor will blink red light.

In the following, let’s move on to an interactive example between IR receiver and IR transmitter module.

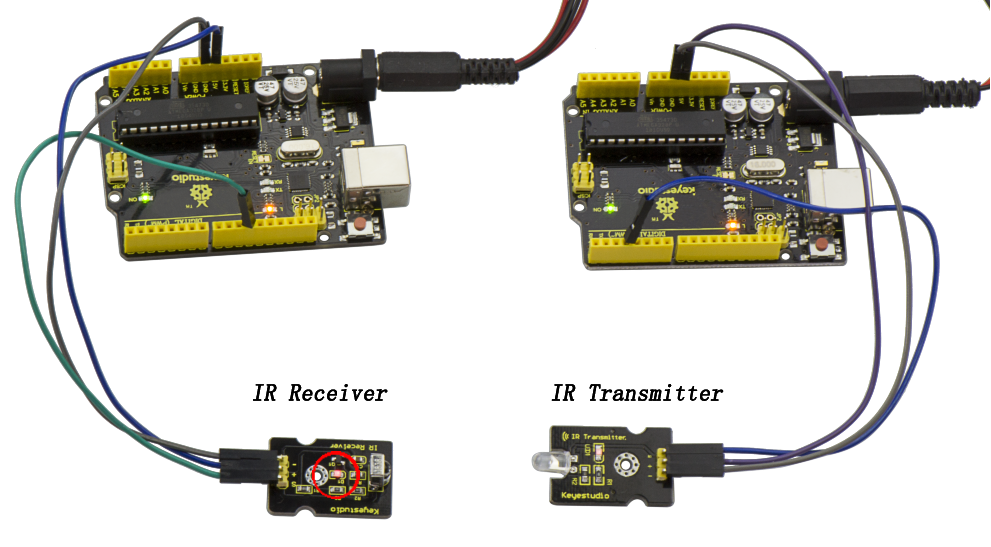

Infrared Remote/Communication:

Hardware Required

Arduino R3 x2

Digital IR Receiver x1

IR Transmitter Module x1

Note: here if you have no two main boards, you can replace it with the breadboard for connection, may be more easier and convenient.

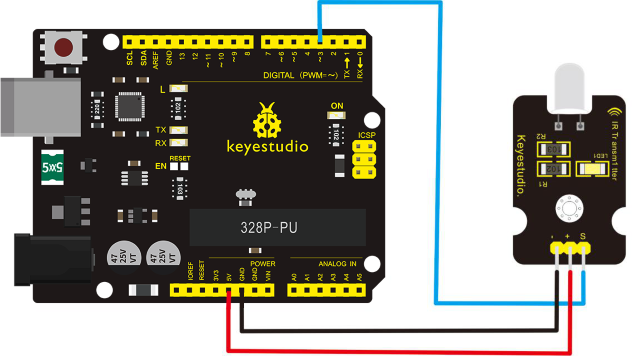

Connection Diagram:

For IR Transmitter:

Notice: Arduino-IR remote only supports D3 as transmitter.

For IR Receiver:

Connect the signal pin to D11 port.

Upload code 2 to the V4.0 connected with IR Transmitter:

int led = 3;

void setup() {

pinMode(led, OUTPUT);

}

void loop() {

digitalWrite(led, HIGH);

delay(1000);

digitalWrite(led, LOW);

delay(1000); }

Upload code 3 to the V4.0 connected with IR Receiver:

#include <IRremote.h>

const int RECV_PIN = 11;

const int LED_PIN = 13;

IRrecv irrecv(RECV_PIN);

decode_results results;

void setup()

{Serial.begin(9600);

irrecv.enableIRIn(); // Start the receiver

}

void loop()

{if (irrecv.decode(&results))

{ if ( results.bits > 0 )

{

int state;

if ( 0x1 == results.value )

{

state = HIGH;

}

else

{

state = LOW;

}

digitalWrite( LED_PIN, state );

}

irrecv.resume(); // prepare to receive the next value

}}

Result:

When IR Receiver module receives the infrared signal from IR Transmitter, D1 led on the IR Receiver module will blink.

When IR Receiver module receives the infrared signal from IR Transmitter, D1 led on the IR Receiver module will blink.

Project 35: Pulse Rate Monitor

Description

This module makes use of a ultra-clear infrared LED and a phototransistor to detect the pulse in your finger. The red LED will flash in time with your pulse.

Working principle

Shine the bright LED onto one side of your finger while the phototransistor on the other side of your finger picks up the amount of transmitted light. The resistance of the phototransistor will vary slightly as the blood pulses through your finger.

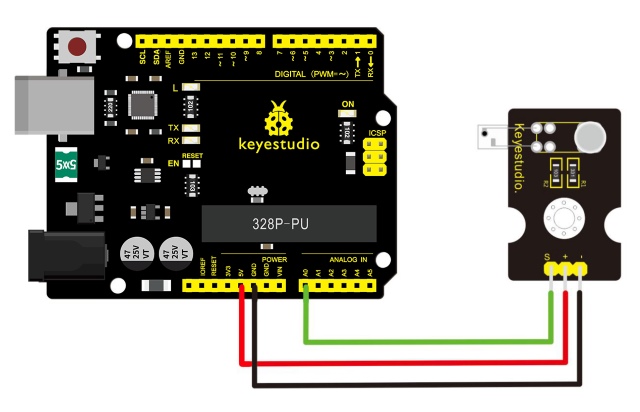

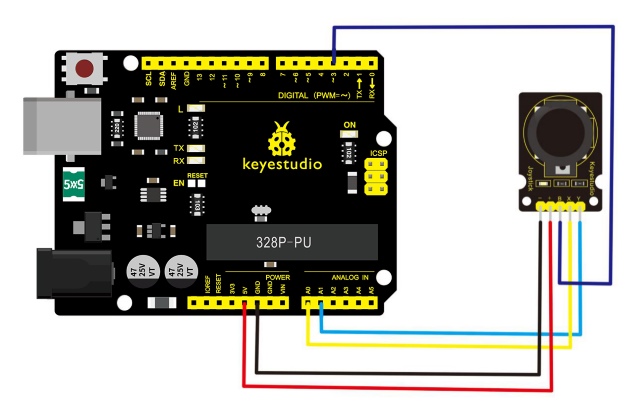

Connection Diagram

Firstly you need to prepare the following parts before making a test.

V4.0 Board*1

Pulse module*1

USB Cable*1

Jumper Wire*3

Connect the Signal pin of module to Analog A0 of V4.0 board, the positive pin to 5V port, the negative pin to GND port.

Sample Code

Copy and paste the code below to Arduino software.

///////////////////////////////////////////////////////////////

int ledPin = 13;

int sensorPin = 0;

double alpha = 0.75;

int period = 20;

double change = 0.0;

void setup()

{

pinMode(ledPin, OUTPUT);

Serial.begin(115200);

}

void loop()

{

static double oldValue = 0;

static double oldChange = 0;

int rawValue = analogRead(sensorPin);

double value = alpha * oldValue + (1 - alpha) * rawValue;

Serial.print(rawValue);

Serial.print(",");

Serial.println(value);

oldValue = value;

delay(period);

}

///////////////////////////////////////////////////////////////

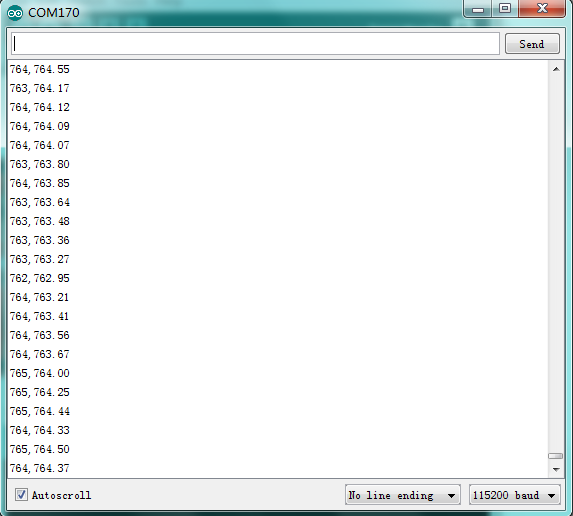

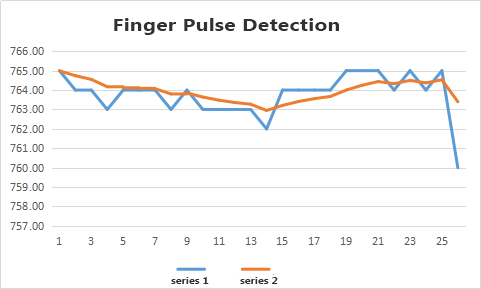

Example Result

Wire it up well as the above diagram, then upload well the code to the board and click the icon of serial monitor on the upper right corner of Arduino software. Set the baud rate as 115200, you will see the data is displayed on the monitor.

You can copy and paste the data to the excel, finally it will generate the corresponding picture shown below.

Project 36: Joystick

Description

Lots of robot projects need joystick. This module provides an affordable solution. By simply connecting to two analog inputs, the robot is at your commands with X, Y control. It also has a switch that is connected to a digital pin.

Specification

Supply Voltage: 3.3V to 5V

Interface: Analog x2, Digital x1

Size: 40*28mm

Weight: 12g

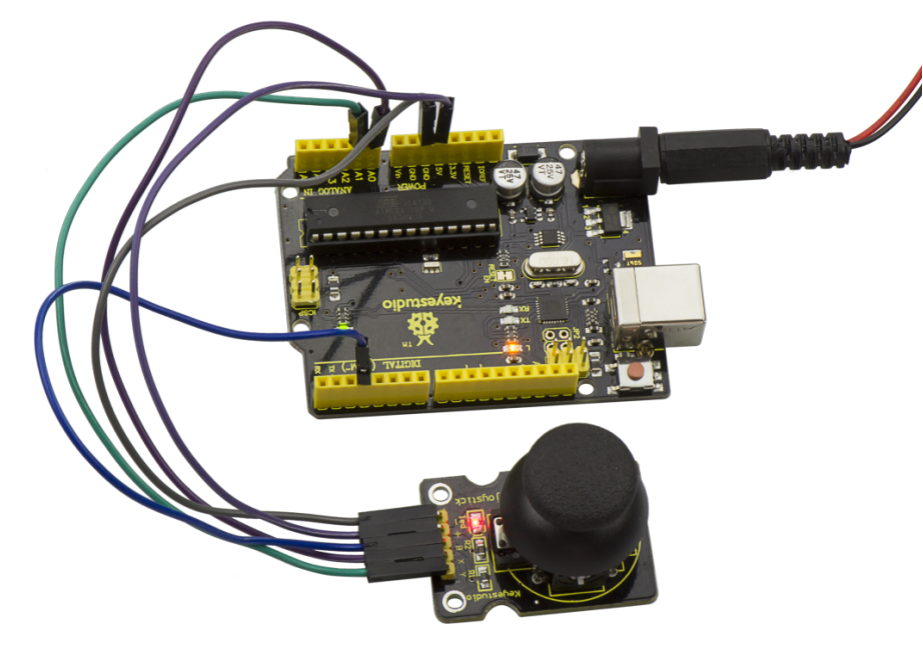

Connection Diagram

Firstly you need to prepare the following parts before connection.

V4.0 Board*1

Joystick module*1

USB Cable*1

Jumper Wire*5

Connect the Y pin of module to Analog A1 of V4.0 board, connect the X pin to Analog A0, B pin to Digital 3; Connect negative pin to GND port, positive pin to 5V port.

Sample Code

Copy and paste the code below to Arduino software.

///////////////////////////////////////////////////////////////

int JoyStick_X = 0; //x

int JoyStick_Y = 1; //y

int JoyStick_Z = 3; //key

void setup()

{

pinMode(JoyStick_Z, INPUT);

Serial.begin(9600); // 9600 bps

}

void loop()

{

int x,y,z;

x=analogRead(JoyStick_X);

y=analogRead(JoyStick_Y);

z=digitalRead(JoyStick_Z);

Serial.print(x ,DEC);

Serial.print(",");

Serial.print(y ,DEC);

Serial.print(",");

Serial.println(z ,DEC);

delay(100);

}

///////////////////////////////////////////////////////////////

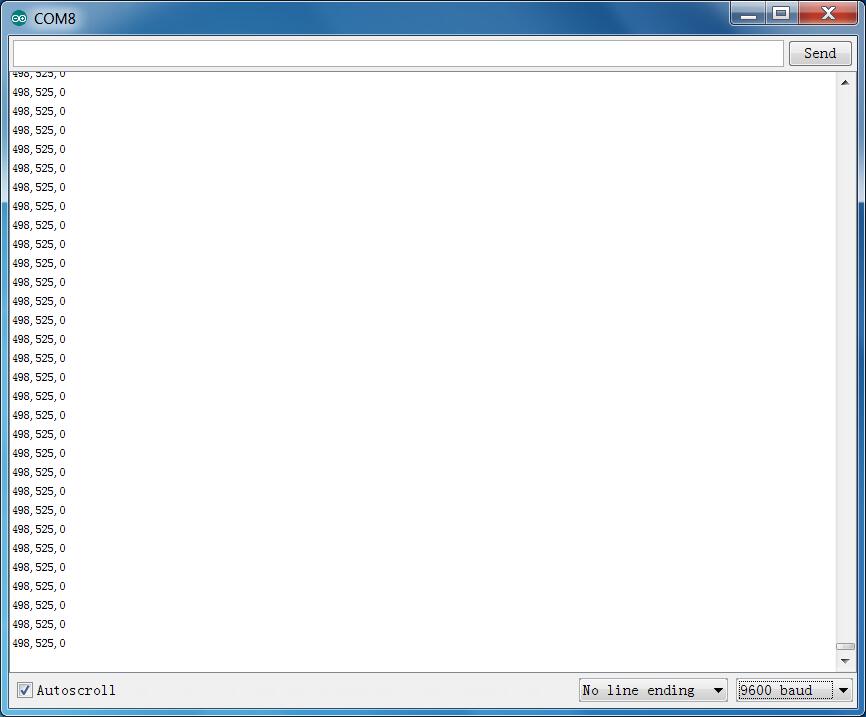

Example Result

Wiring well and uploading the code, open the serial monitor on Arduino software, and set the baud rate as 9600, you will see the value shown below. If push the joystick downward /upward /leftward /rightward, the data will change.

Project 37: Rotary Encoder

Introduction

The rotary encoder can count the pulse outputting times during the process of rotation in positive and reverse direction.

This rotating counting is unlimited, not like potential counting. It can be restored to initial state to count from 0.

Specification

Power Supply: 5V

Interface: Digital

Size: 30*20mm

Weight: 7g

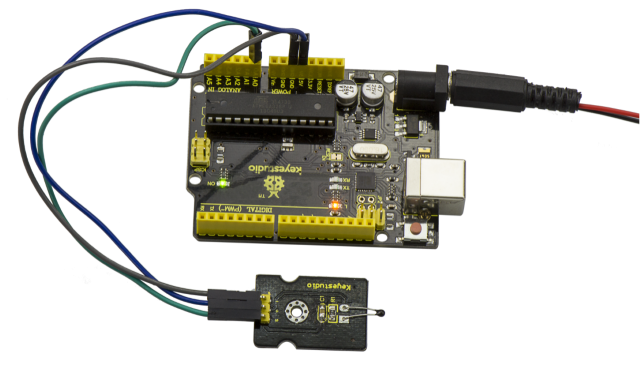

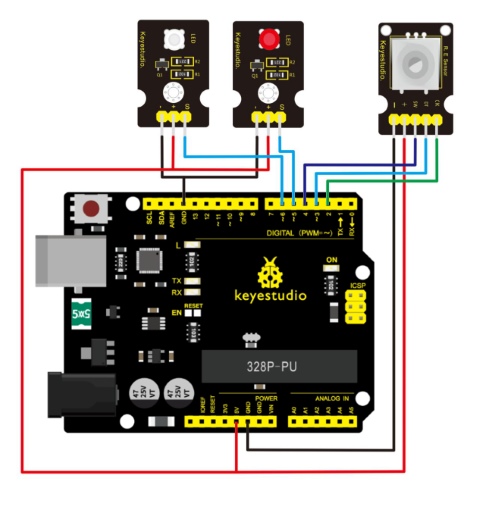

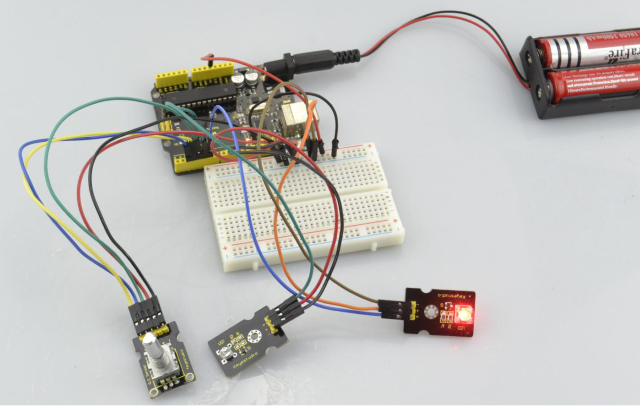

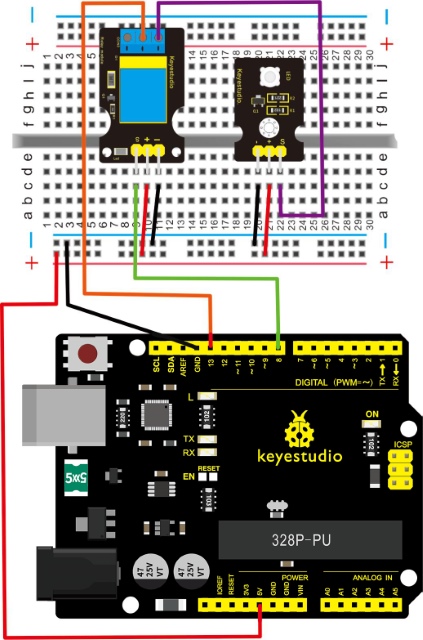

Connection Diagram

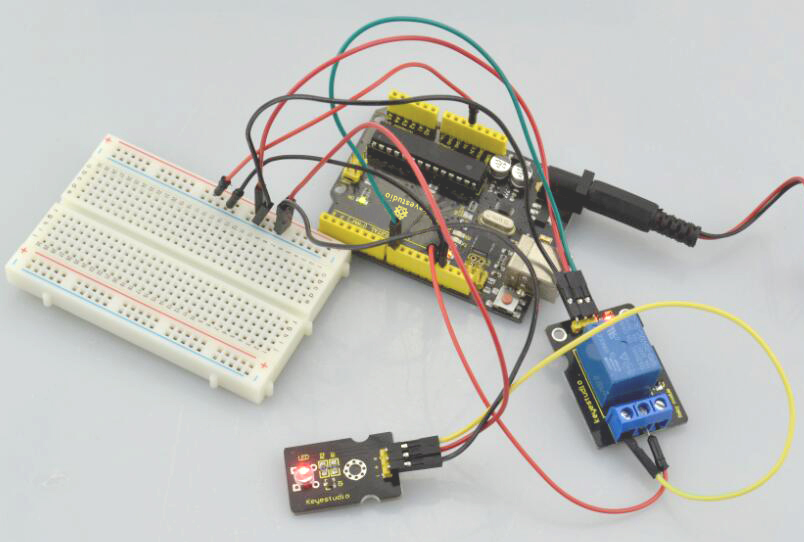

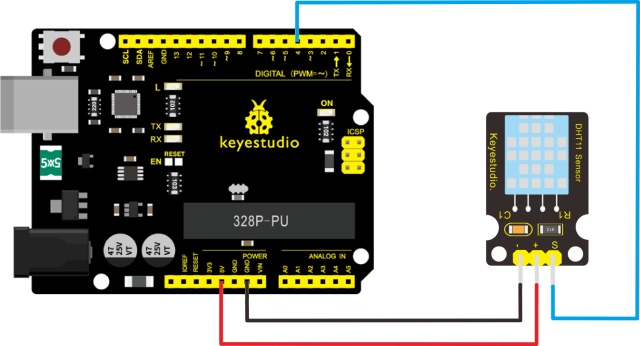

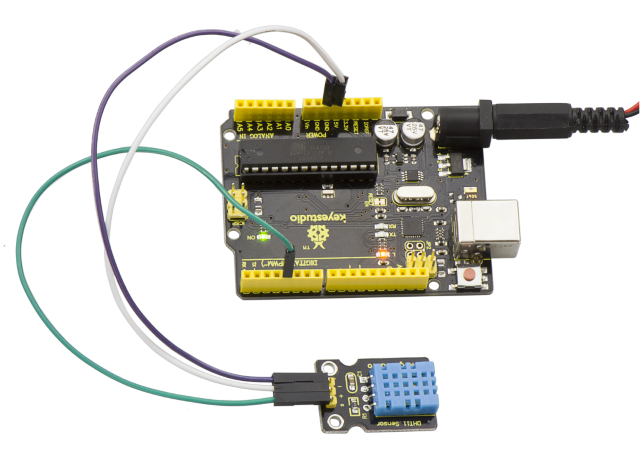

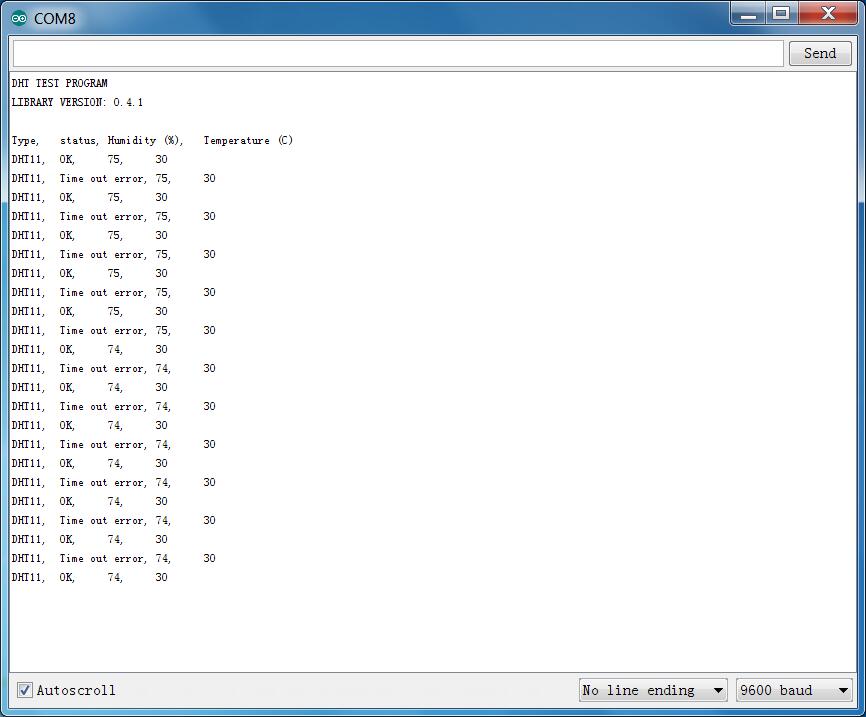

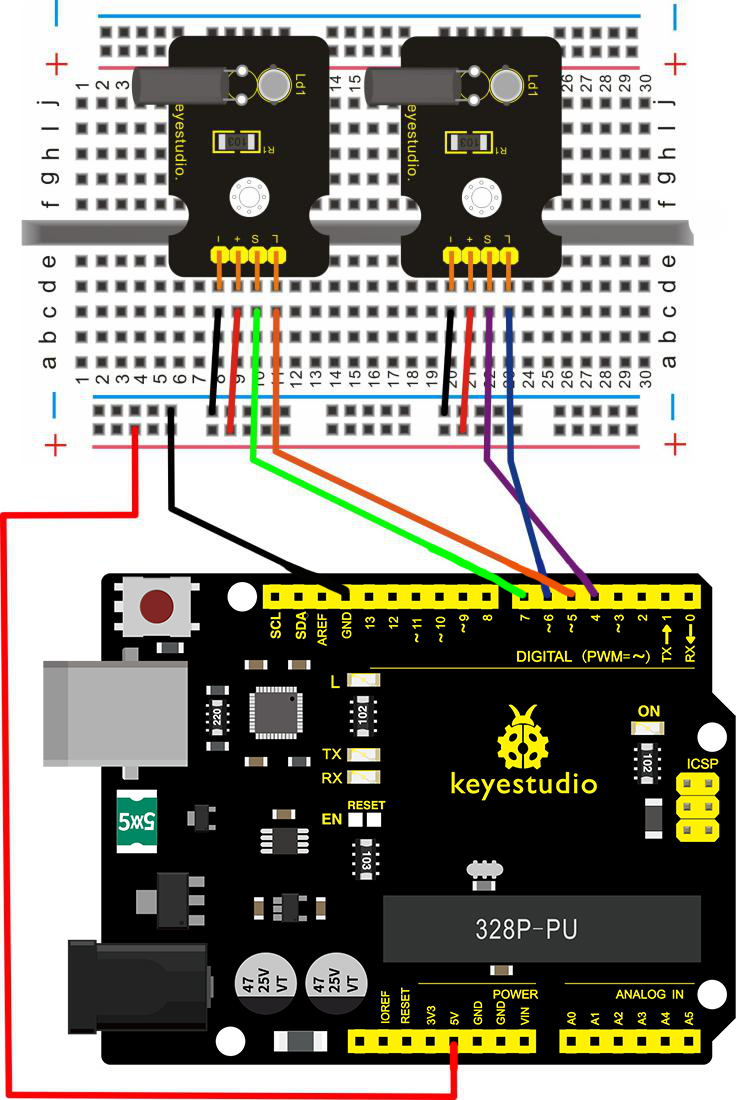

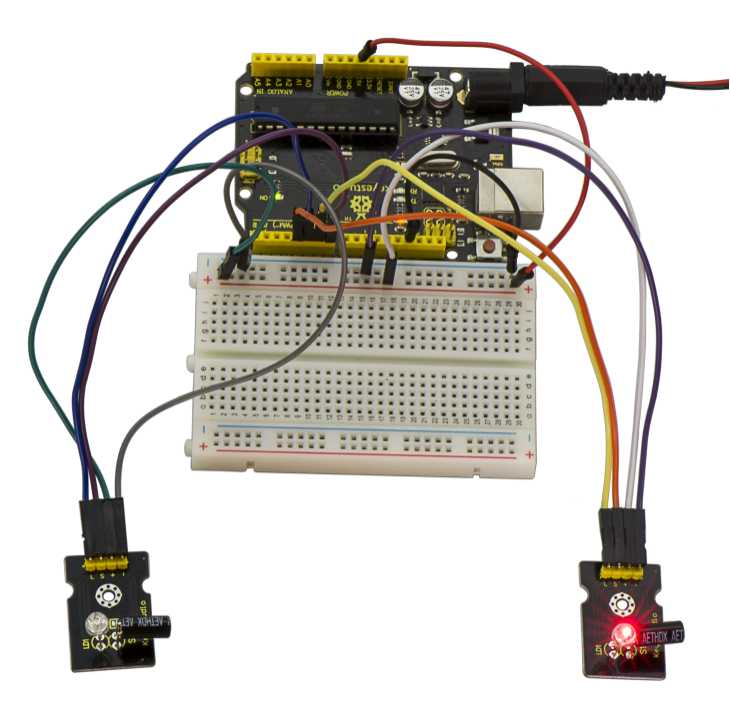

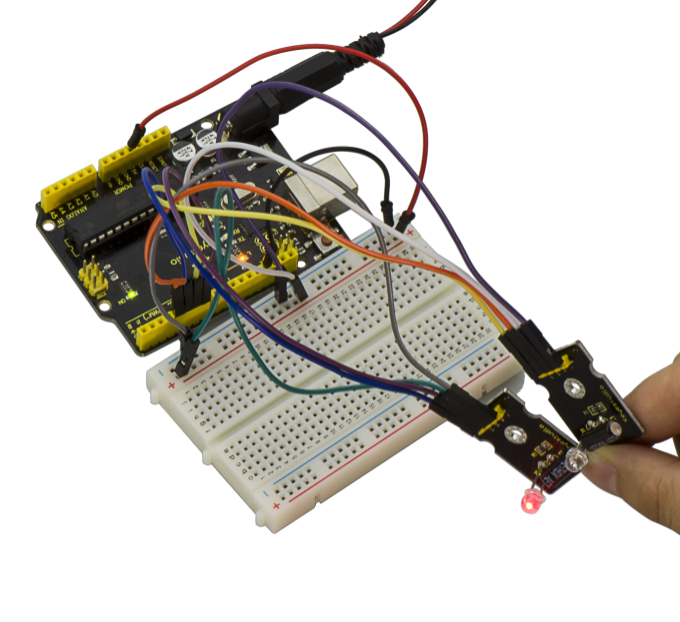

As seen in the diagram, we connect rotary encoder module and two LED modules to the breadboard and V4.0 board.

Use the rotary encoder module to control two LED modules on and off.

Sample Code

///////////////////////////////////////////////////////////////

const int interruptA = 0;

const int interruptB = 1;

int CLK = 2; // PIN2

int DAT = 3; // PIN3

int BUTTON = 4; // PIN4

int LED1 = 5; // PIN5

int LED2 = 6; // PIN6

int COUNT = 0;

void setup()

{

attachInterrupt(interruptA, RoteStateChanged, FALLING);

// attachInterrupt(interruptB, buttonState, FALLING);

pinMode(CLK, INPUT);

digitalWrite(2, HIGH); // Pull High Resistance

pinMode(DAT, INPUT);

digitalWrite(3, HIGH); // Pull High Resistance

pinMode(BUTTON, INPUT);

digitalWrite(4, HIGH); // Pull High Resistance

pinMode(LED1, OUTPUT);

pinMode(LED2, OUTPUT);

Serial.begin(9600);

}

void loop()

{

if (!(digitalRead(BUTTON)))

{

COUNT = 0;

Serial.println("STOP COUNT = 0");

digitalWrite(LED1, LOW);

digitalWrite(LED2, LOW);

delay (2000);

}

Serial.println(COUNT);

}

//-------------------------------------------

void RoteStateChanged() //When CLK FALLING READ DAT

{

if (digitalRead(DAT)) // When DAT = HIGH IS FORWARD

{

COUNT++;

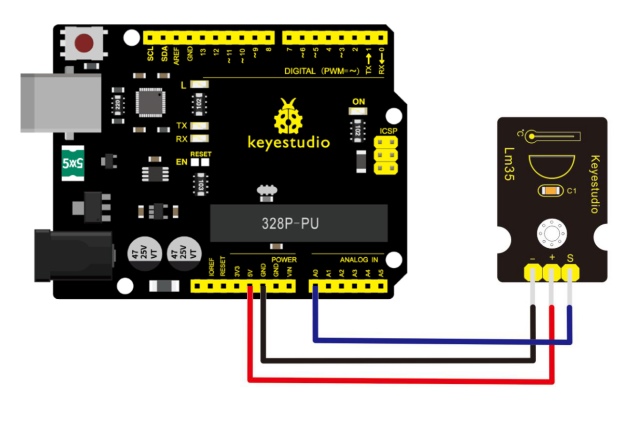

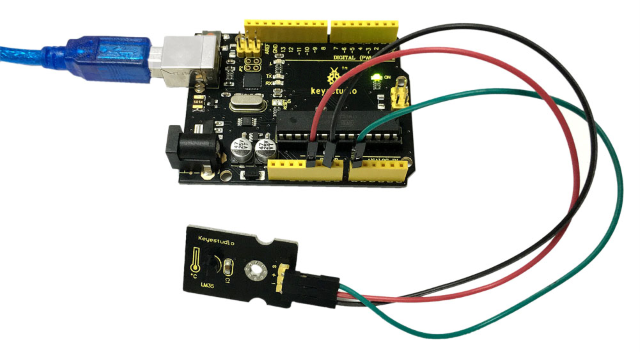

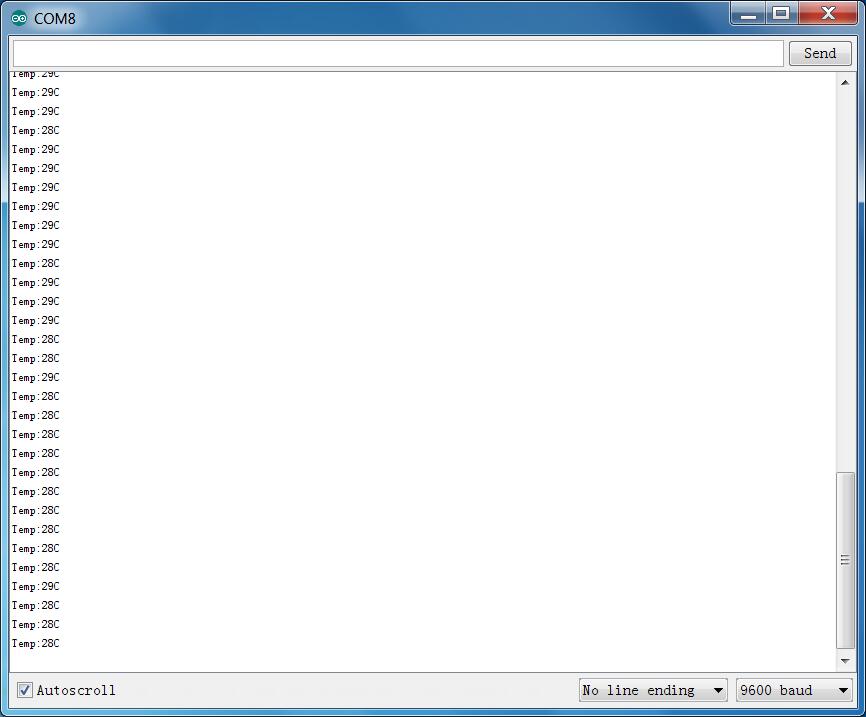

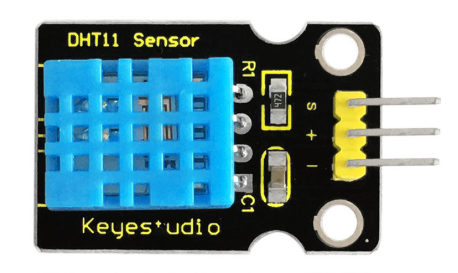

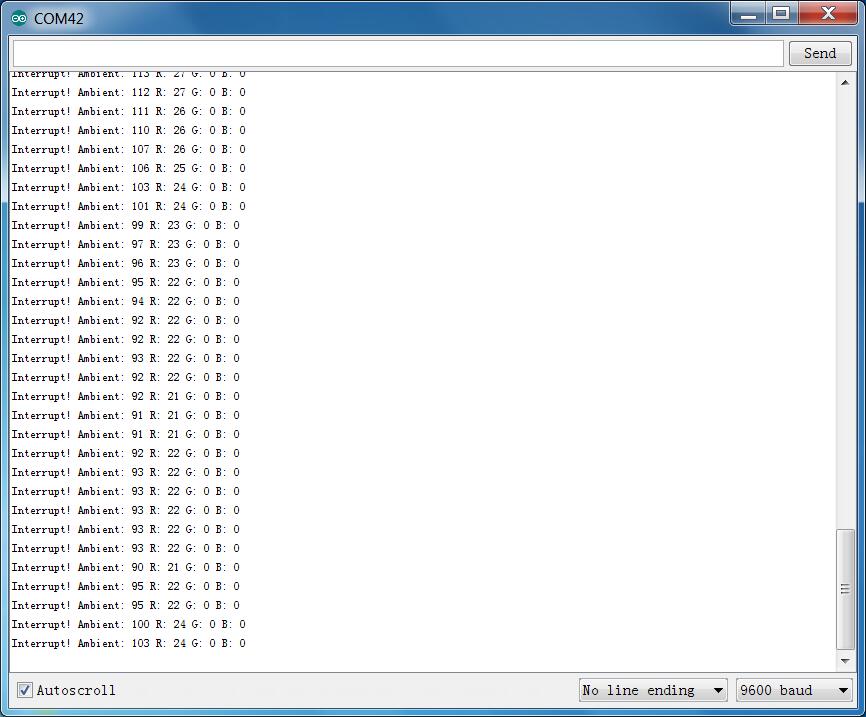

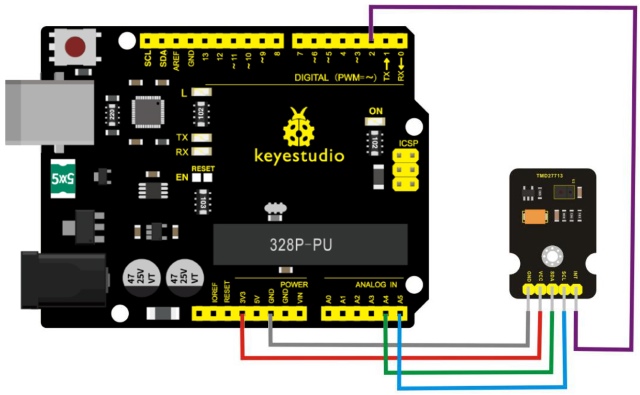

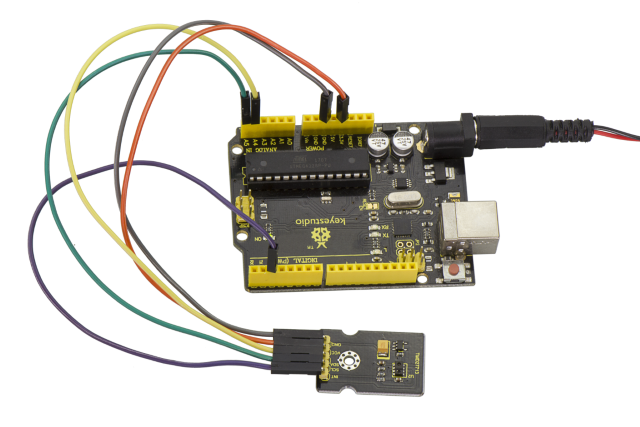

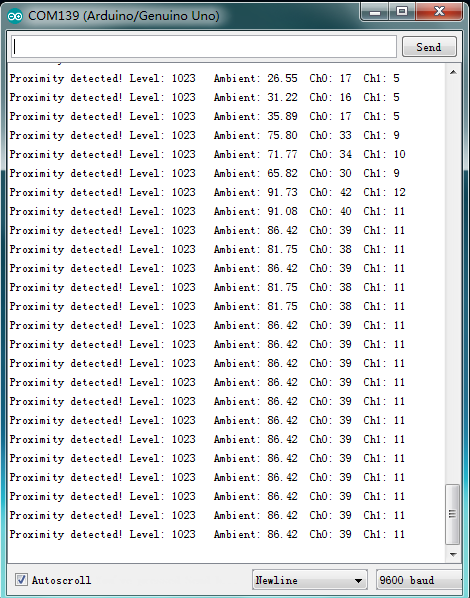

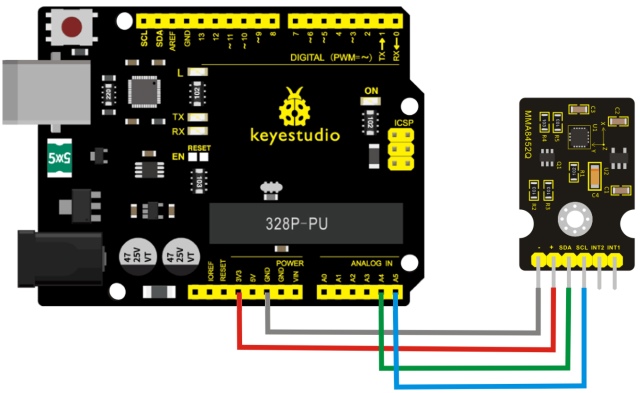

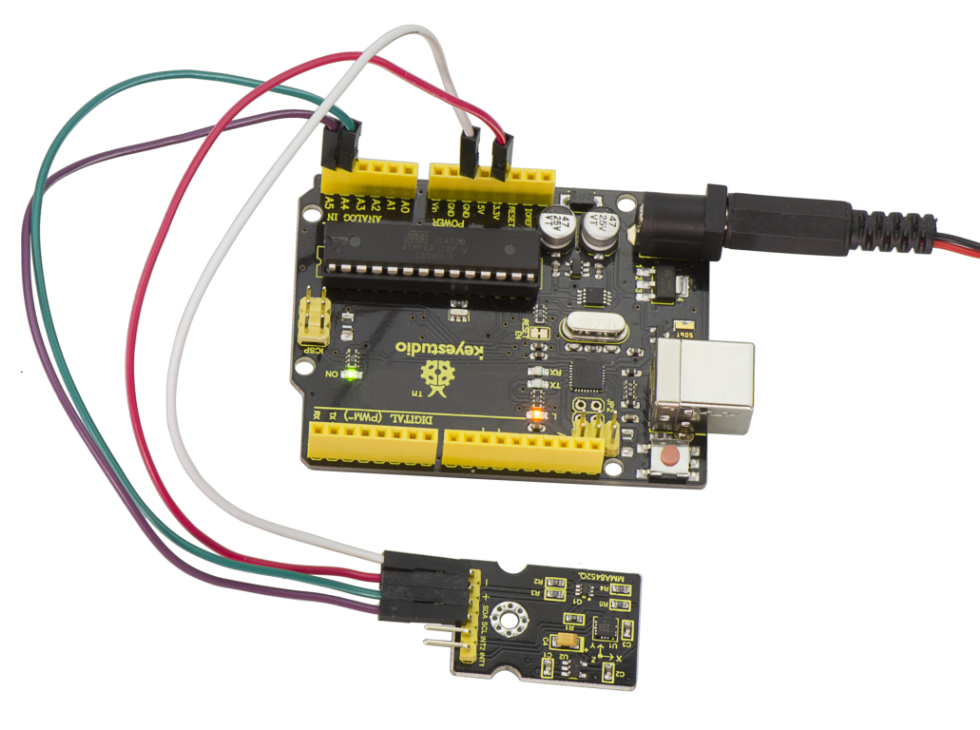

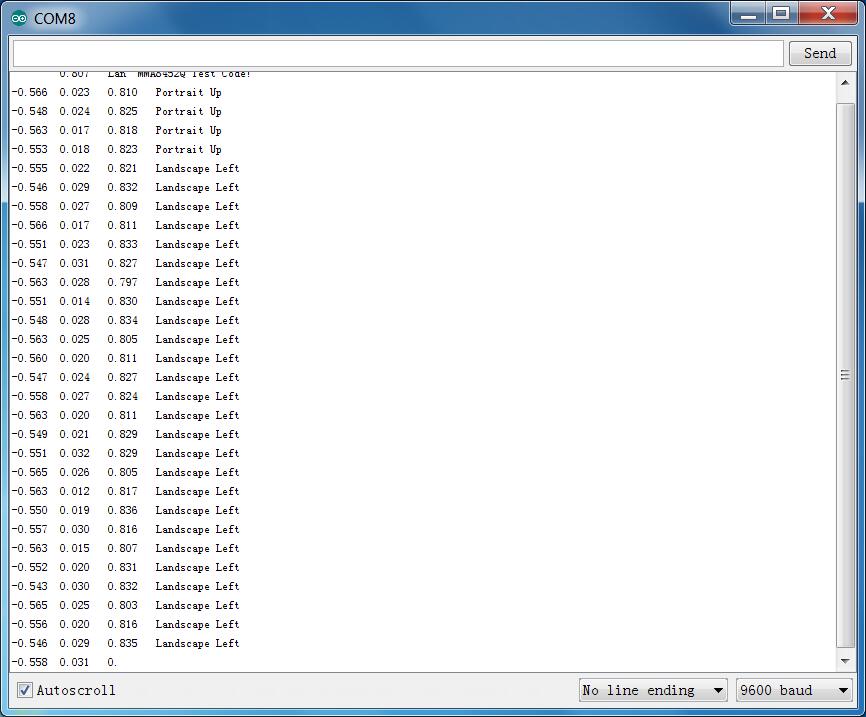

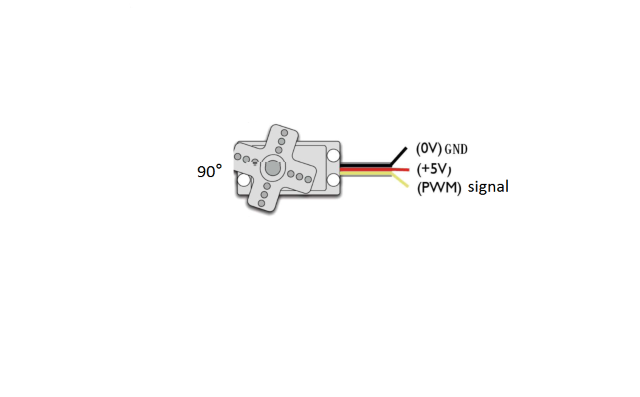

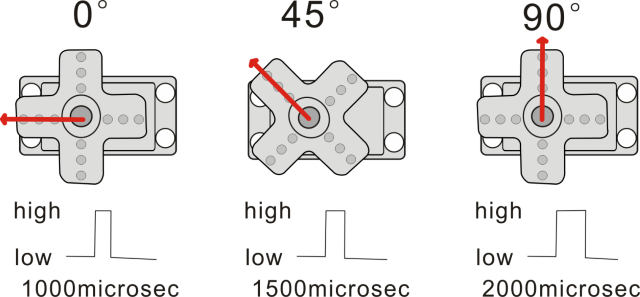

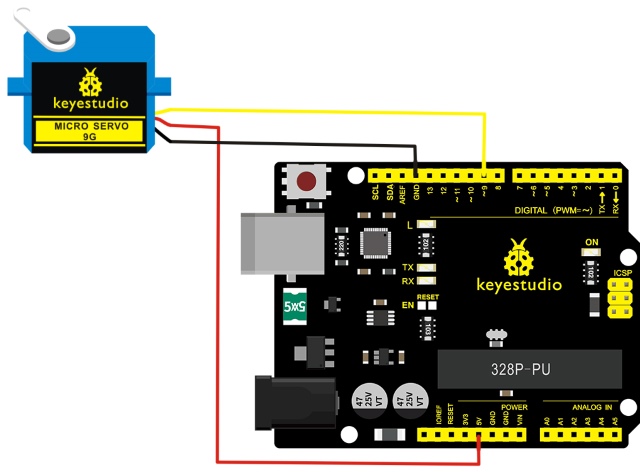

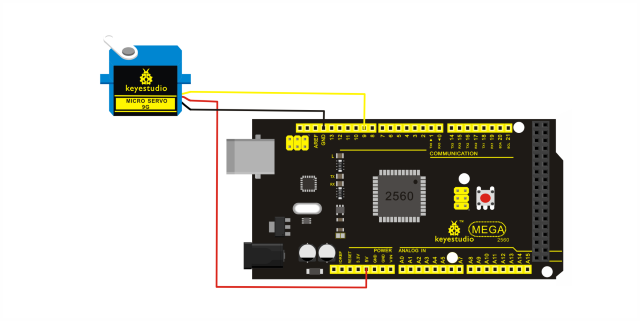

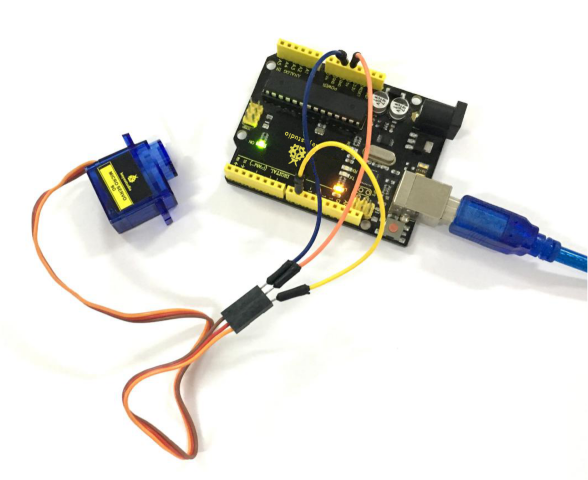

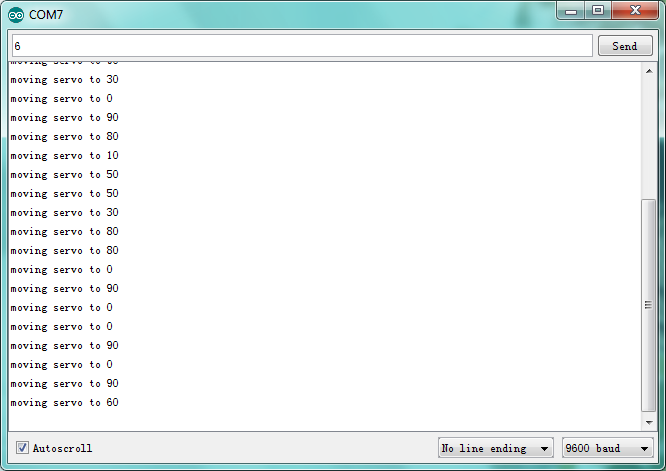

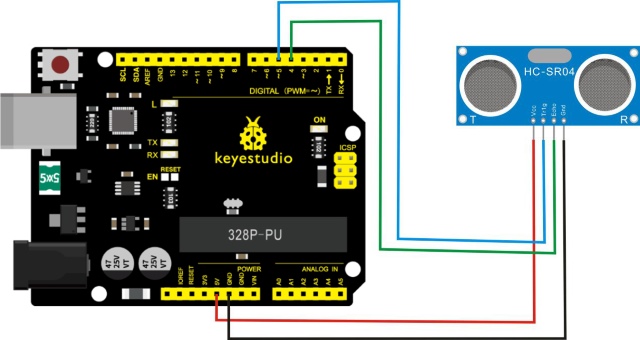

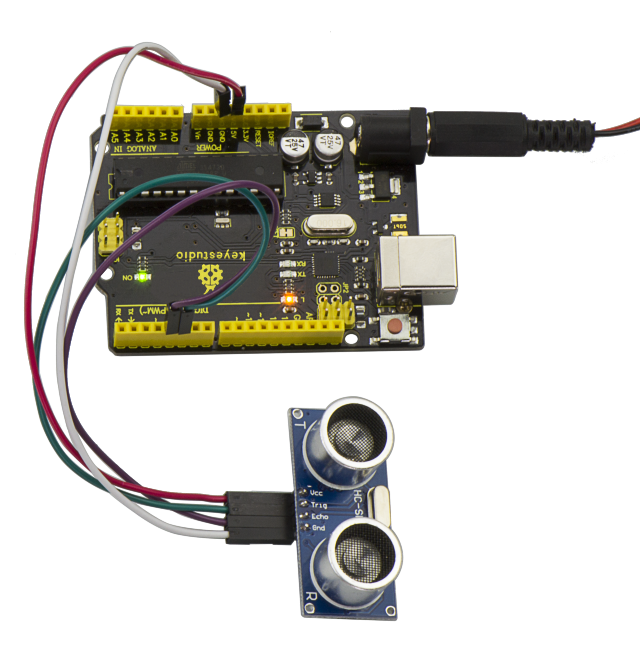

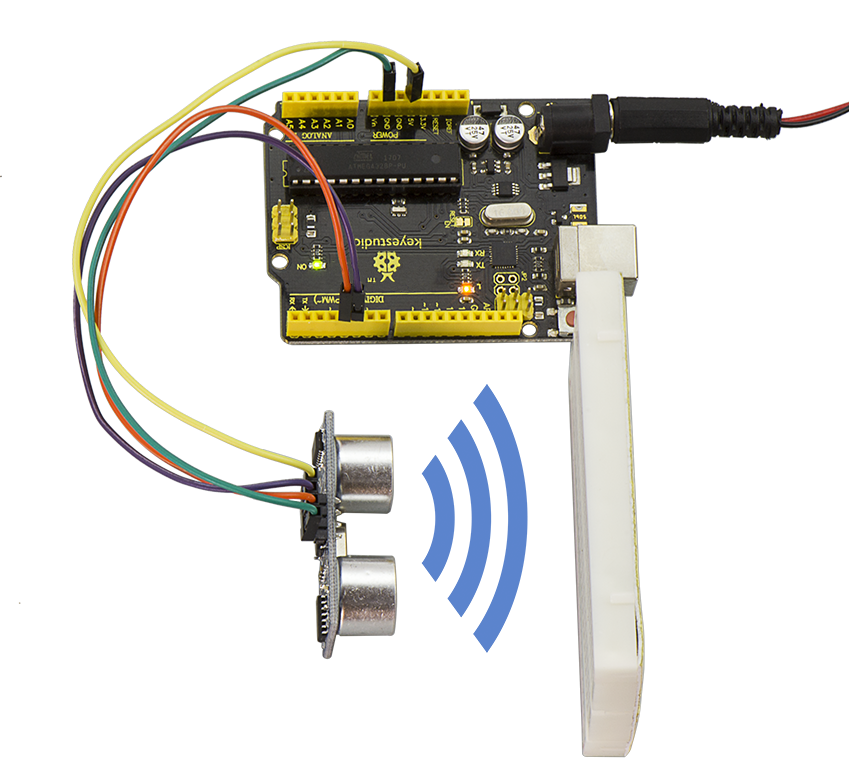

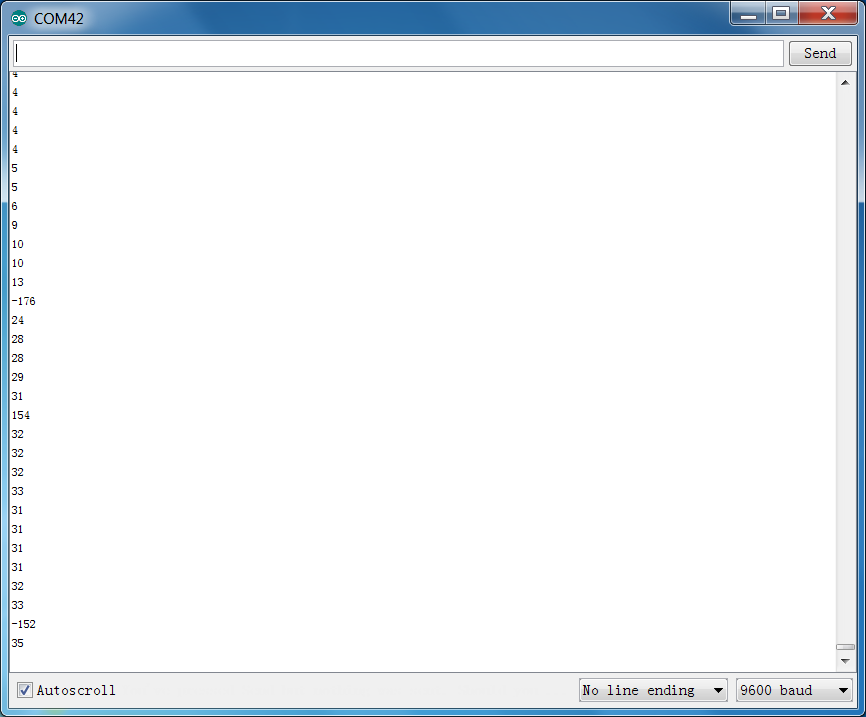

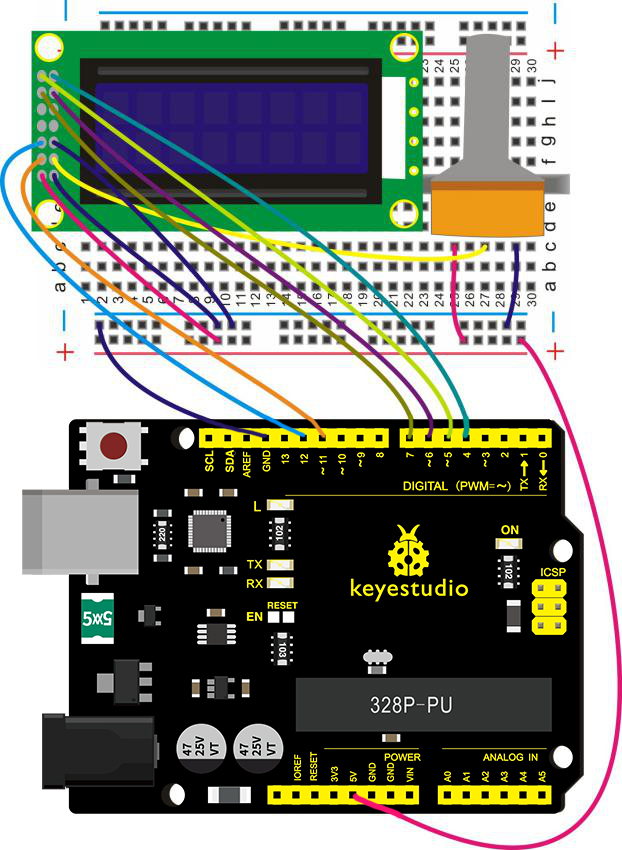

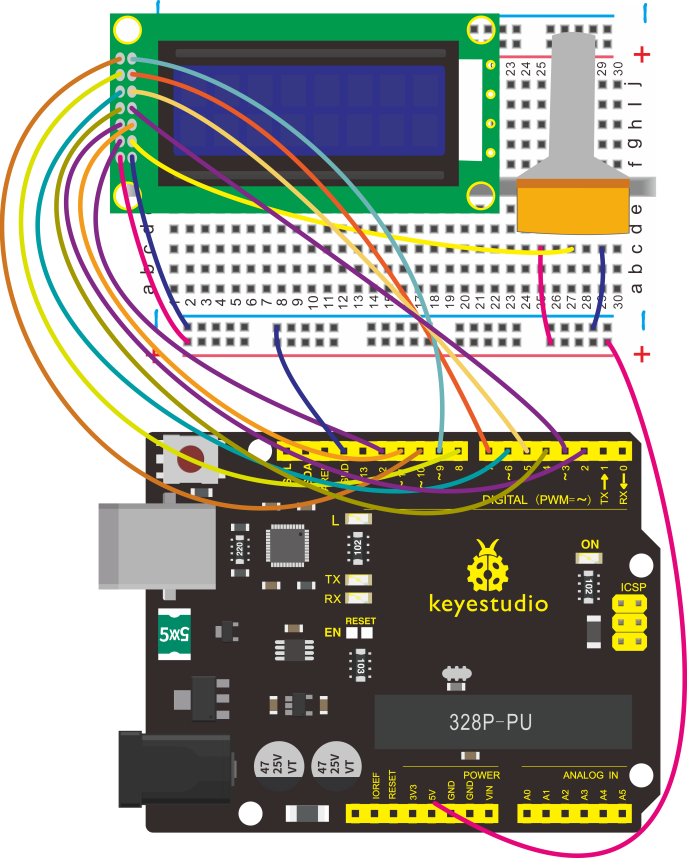

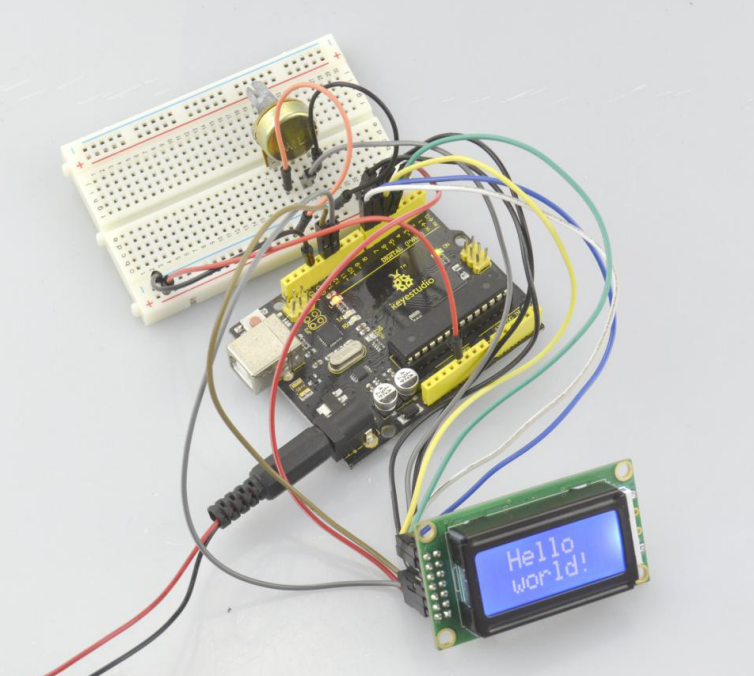

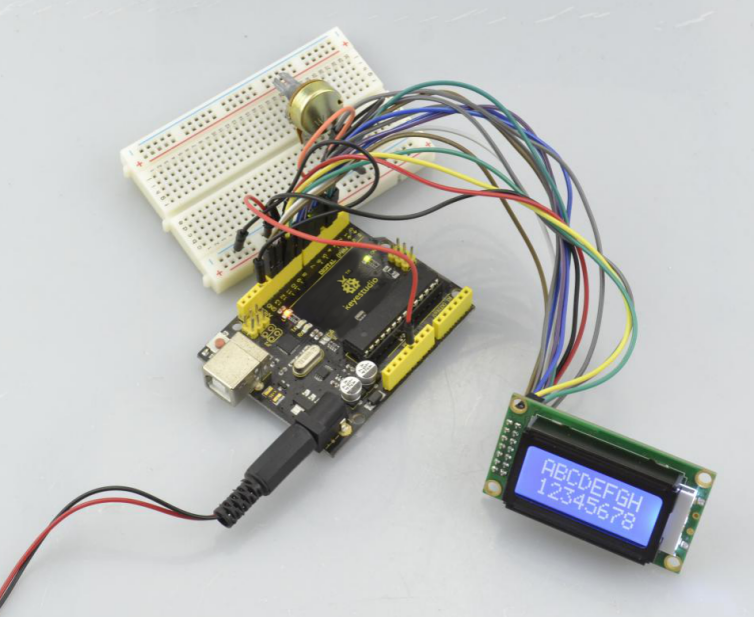

digitalWrite(LED1, HIGH);